Deoxidizing agent for foods and method for preparing deoxidizing agent

A deoxidizer, food technology, applied in food preservation, application, food science and other directions, can solve the problems of low reaction rate, affecting food storage effect, food moisture regain, etc., to achieve good effect, excellent water absorption and drying characteristics, high deoxidation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a preparation method of the deoxidizer, the preparation steps comprising: 1) dissolving the electrolyte with water, adding calcium chloride and stirring evenly; 2) adding a superabsorbent resin to the mixed solution in step 1), After stirring evenly, let it stand for 10-20 minutes to balance the moisture transfer, add filler and silicon dioxide, mix and stir evenly, then add reducing iron powder, and mix for 10-30 minutes, and the mixed material passes through a 30-80 mesh sieve , sealed for subsequent use; 3) after the material in step 2) is cooled, pack it into bags and vacuumize to obtain the deoxidizer of the present invention.

[0026] Preferably, in the bagging and packaging step in step 3), it is preferable to use a packaging film with one-way moisture selective permeation for packaging, so as to effectively prevent the moisture in the deoxidizer content from diffusing into the food.

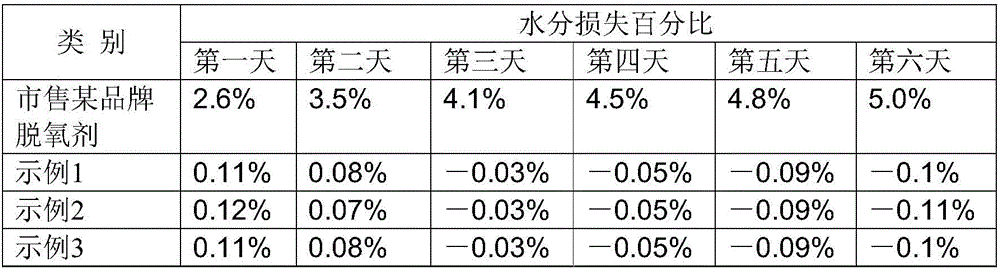

Embodiment 1

[0028] A deoxidizer for food, which is made of the following components by weight percentage: reduced iron powder: 40%, sodium chloride 2%, calcium chloride: 5%, silicon dioxide: 21%, polyacrylic acid Department of super absorbent resin: 5%, bentonite: 21% and water 6%. The preparation step of described deoxidizer comprises:

[0029] 1) After dissolving sodium chloride with water, add calcium chloride and stir to mix evenly;

[0030] 2) Add polyacrylic acid superabsorbent resin to the mixed liquid in step 1), stir evenly and let it stand for 10 minutes. After the water transfer is balanced, add bentonite and silicon dioxide, mix and stir evenly, add reducing iron powder, Sealed and mixed for 20 minutes, then, the mixed material passed through a 60-mesh sieve, and sealed for later use;

[0031] 3) After the material in step 2) is cooled, it is transferred to an automatic packaging machine for bagging and packaging, and the deoxidizer is obtained after vacuuming.

Embodiment 2

[0033] A deoxidizer for food, which is made of the following components by weight percentage: reduced iron powder: 50%, sodium bromide: 1%, sodium iodide: 5%, calcium chloride: 5%, di Silica: 15%, polyacrylamide superabsorbent resin: 1%, bentonite: 5%, diatomaceous earth: 10%, water: 8%. The preparation step of described deoxidizer comprises:

[0034] 1) After dissolving sodium bromide and sodium iodide with water, add calcium chloride and stir to mix evenly;

[0035] 2) Add polyacrylamide-based superabsorbent resin to the mixture in step 1), stir evenly and let it stand for 30 minutes. After the water transfer is balanced, add bentonite, diatomaceous earth and silicon dioxide, mix well and then add Reduced iron powder, sealed and mixed for 15 minutes, then, the mixed material passed through a 60-mesh sieve, and sealed for later use;

[0036] 3) After the material in step 2) is cooled, it is transferred to an automatic packaging machine for bagging and packaging, and the deo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com