Deoxidant for foods and with moisture-absorption function and preparation method of deoxidant

A deoxidizer and food technology, applied in food preservation, food ingredients, applications, etc., can solve the problems of discounted deoxidation performance and poor effect, and achieve good effect, high deoxidation efficiency, and less component dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

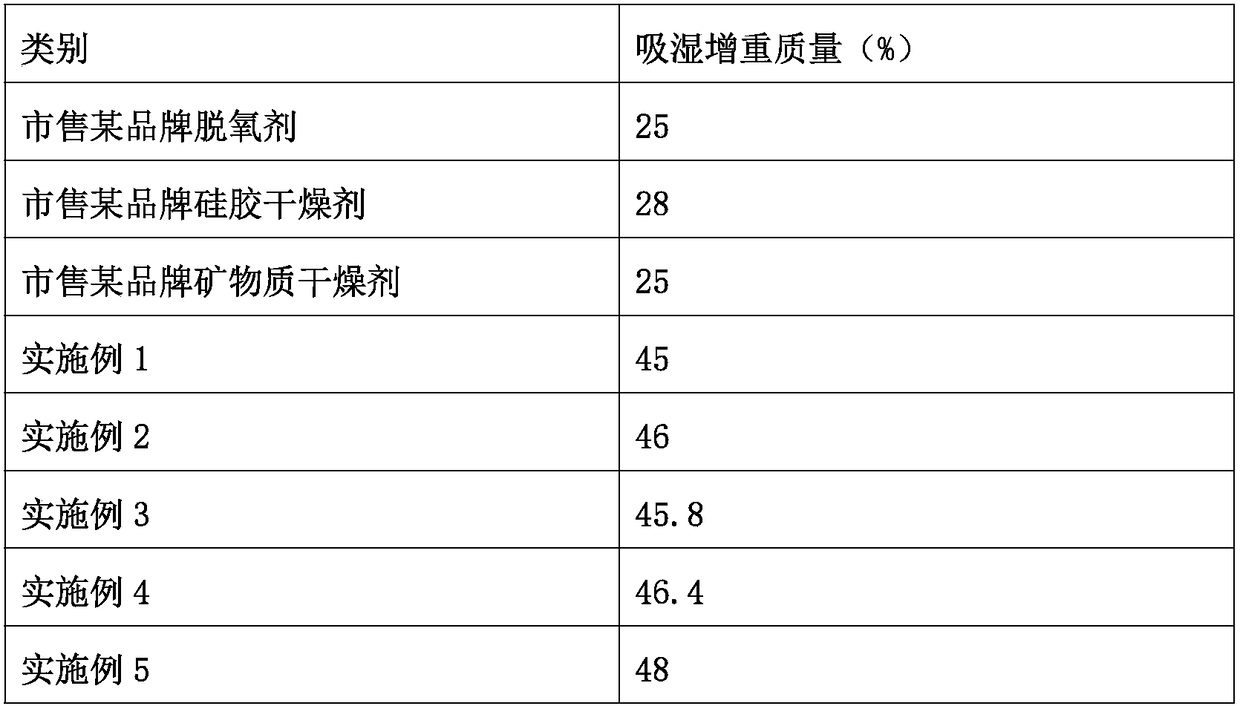

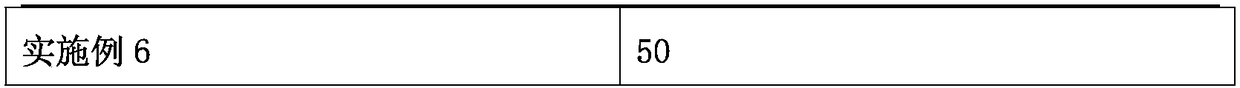

Examples

Embodiment 1

[0024] A food deoxidizer with moisture absorption function, comprising the following components: iron powder, metal chloride, water retention agent and gas adsorbent; the iron powder added content is 40%; the metal chloride added content is 45%, The added content of water retaining agent is 15% and the added content of gas adsorbent is 0%.

[0025] The preparation step of described deoxidizer comprises:

[0026] 1) First mix metal chloride and water retaining agent to make a mixture,

[0027] 2) Add a gas adsorbent to the mixed solution in step 1), stir evenly and let it stand for 2 minutes, then add reducing iron powder, and mix in an airtight manner for 5 minutes, pass the mixed material through a 30-80 mesh sieve, and seal it for later use;

[0028] 3) After the material in step 2) is cooled, quantitatively pack it into bags and vacuumize to obtain the deoxidizer.

[0029]Among them, the iron powder has a particle size of 100 mesh; the metal chloride is calcium chloride; ...

Embodiment 2

[0031] A deoxidizer for food with moisture absorption function, comprising the following components: iron powder, metal chloride, water retention agent and gas adsorbent; the iron powder added content is 80%; the metal chloride added content is 4%, The added content of water retaining agent is 15% and the added content of gas adsorbent is 1%.

[0032] The preparation step of described deoxidizer comprises:

[0033] 1) First mix metal chloride and water retaining agent to make a mixture,

[0034] 2) Add gas adsorbent to the mixed liquid in step 1), stir evenly and let it stand for 2 minutes, then add reducing iron powder, and mix in airtight for 5 minutes, pass the mixed material through a 30-80 mesh sieve, seal it for later use;

[0035] 3) After the material in step 2) is cooled, quantitatively pack it into bags and vacuumize to obtain the deoxidizer.

[0036] Among them, the iron powder has a particle size of 100 mesh; the metal chloride is calcium chloride; the water-reta...

Embodiment 3

[0038] A deoxidizer for food with moisture absorption function, comprising the following components: iron powder, metal chloride, water retention agent and gas adsorbent; the iron powder added content is 60%; the metal chloride added content is 3%, The added content of water retaining agent is 35% and the added content of gas adsorbent is 2%.

[0039] The preparation step of described deoxidizer comprises:

[0040] 1) First mix metal chloride and water retaining agent to make a mixture,

[0041] 2) Add gas adsorbent to the mixed liquid in step 1), stir evenly and let it stand for 2 minutes, then add reducing iron powder, and mix in airtight for 5 minutes, pass the mixed material through a 30-80 mesh sieve, seal it for later use;

[0042] 3) After the material in step 2) is cooled, quantitatively pack it into bags and vacuumize to obtain the deoxidizer.

[0043] Among them, the iron powder has a particle size of 80 mesh; the metal chloride is calcium chloride; the water-retai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com