Method for preparing Cf/TiC-TiB2 surface modified layer through utilizing friction stir processing

A surface modification layer and friction stir technology, applied in coating, metal material coating process and other directions, can solve the problems of small application scope and high cost of metal surface modification technology, reduce production cost, improve fatigue resistance, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

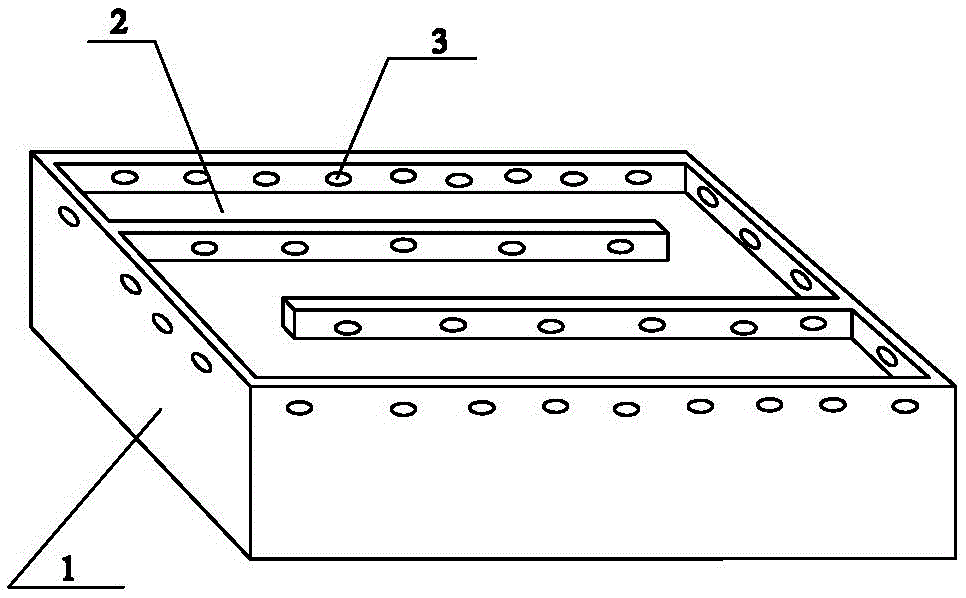

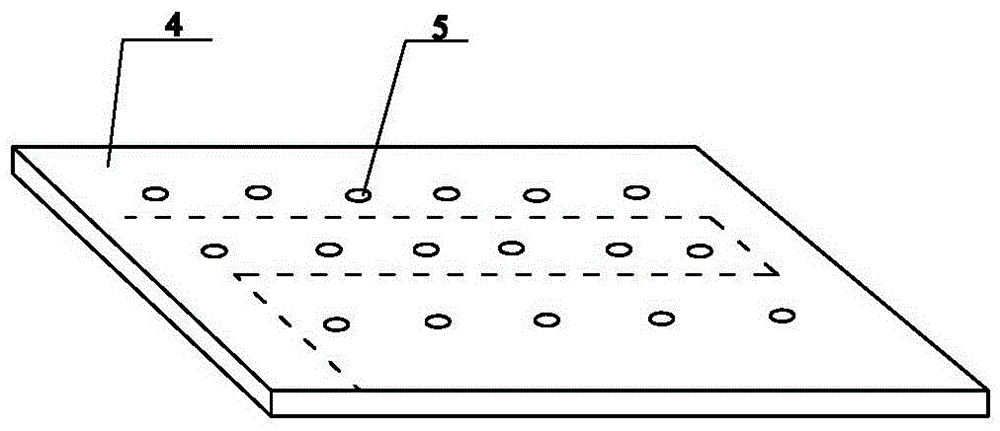

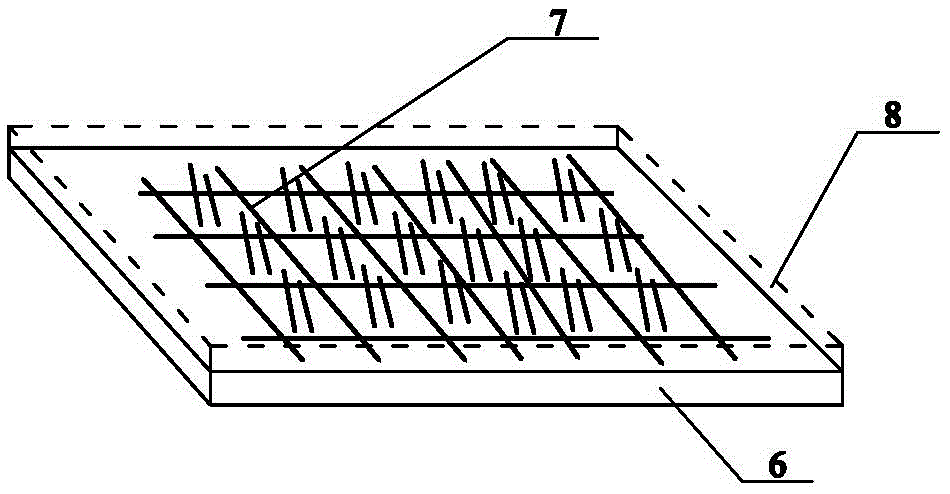

[0022] Such as figure 1 , figure 2 and image 3 As shown, a preparation of C by friction stir processing (FSP for short) f / TiC-TiB 2 The method for surface modification layer, it comprises the following steps:

[0023] First, the upper surface of the substrate 1 that needs surface modification is milled with an "S"-shaped groove 2 (groove depth 2~5mm), and a small hole 3 of about 1 mm is opened around the "S" groove 2 (the size of the small hole 3 The quantity depends on the peripheral length of the "S" slot 2, generally one should be opened every 15mm or so);

[0024] Secondly, find the same material as the base material 1 to make the cover plate 4, and its thickness is 0.5~1mm. The size of the cover plate 4 should be the same as that of the base material 1. The hole 5 has a diameter of 1 mm, and the position of the small hole 5 is consistent w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com