Efficient clean bio-additive capable of preventing spontaneous combustion of lignite and slowing down heat loss and preparation method thereof

A biological additive and lignite technology, applied in the field of fuel additives, can solve the problems of high energy consumption, secondary pollution of the environment, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

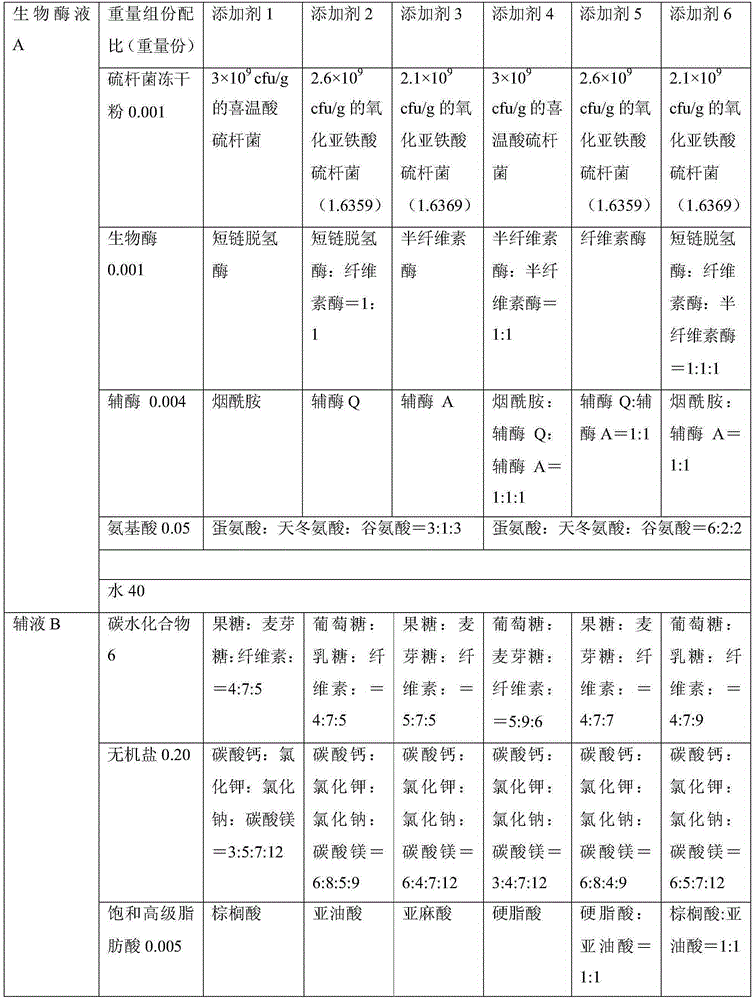

Examples

Embodiment 1

[0037] Embodiment 1. Preparation of the environmental protection and energy-saving additive of the present invention

[0038] (1) Preparation of Thiobacillus freeze-dried powder

[0039] The strains are as follows

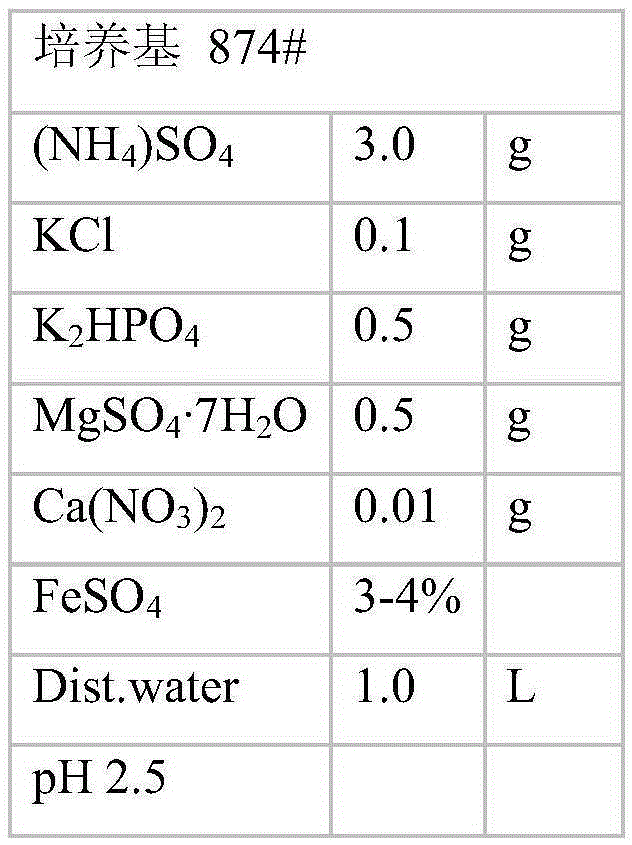

[0040] Thiobacillus ferrooxidans (1.6359), Thiobacillus ferrooxidans (1.6369), Thiobacillus thermophile (1.7296), the medium formula is 874 liquid medium provided by CGMCC, the formula is as follows:

[0041]

[0042] After inoculating 2% of the bacterial seed solution into the liquid medium, it is placed in a constant temperature shaking incubator, and carried out shaking and expanding culture under the conditions of 30-32 ° C and 200 r / min, and continuously expanding the culture for three generations, each generation is 24 hours. Centrifuge the culture solution at 6000rpm for 20min to obtain the bacteria sludge, add lyoprotectant (sodium glutamate 4%, lactose 5%, trehalose 2%, skim milk 18%) to make a bacterial suspension, add the amount of lyoprotectant Make ...

Embodiment 2

[0056] Embodiment 2. Additives to the test of improving coal combustion and emissions performance

[0057] Step 1. Dilute the biological additives 1-18 of Example 1 with water at a volume ratio of 120 times before use.

[0058] Step 2. Prepare the Coal

[0059] There are two types of test coal, one is medium coal and the other is raw coal.

[0060] After the medium coal is mixed, it is divided into 10 points, one part is the control medium coal, and the remaining 9 parts are the test group.

[0061] After the raw coal is mixed, it is evenly divided into 10 points, one part is the control raw coal, and the remaining 9 parts are the test group.

[0062] A total of 18 test coals were randomly matched with the 18 additives in Table 1-3.

[0063] Step 3. After spraying the additive randomly distributed on each test coal and leaving it to stand for 5 days, test the sulfur content in the coal, and the results are shown in Table 4 below:

[0064] Additive No. coal sampl...

Embodiment 3

[0070] Embodiment 3. Prevent spontaneous combustion of coal piles and slow down the loss of calorific value test

[0071] A power plant uses lignite to generate electricity, and the coal storage yard has long-term spontaneous combustion problems, and a coal storage control test was carried out in the coal storage yard.

[0072] Step 1. Dilute the biological additive with water at a volume ratio of 120 times before use.

[0073] Step 2. Prepare the Coal

[0074] There are two groups of test coal, one is about 5000 tons of raw coal (unsprayed) and the other is about 5000 tons of test coal (sprayed with biological additives). The shape, height, size and storage time of the two groups of coal piles are the same.

[0075] Step 3. Regularly compare whether the two coal piles are spontaneously combusted; regularly sample and compare the changes in the calorific value of the coal piles (when sampling, take 2 kg of coal powder from 10 corresponding positions of the two coal piles and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com