A kind of special white oil for polystyrene and preparation method thereof

A polystyrene and white oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., can solve the problem of difficult and effective processing of high-viscosity PS white oil, limited cycloalkane content, and limited PS white oil performance To achieve the effects of ensuring application performance and safety, increasing the content of naphthenes, and excellent light and heat stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

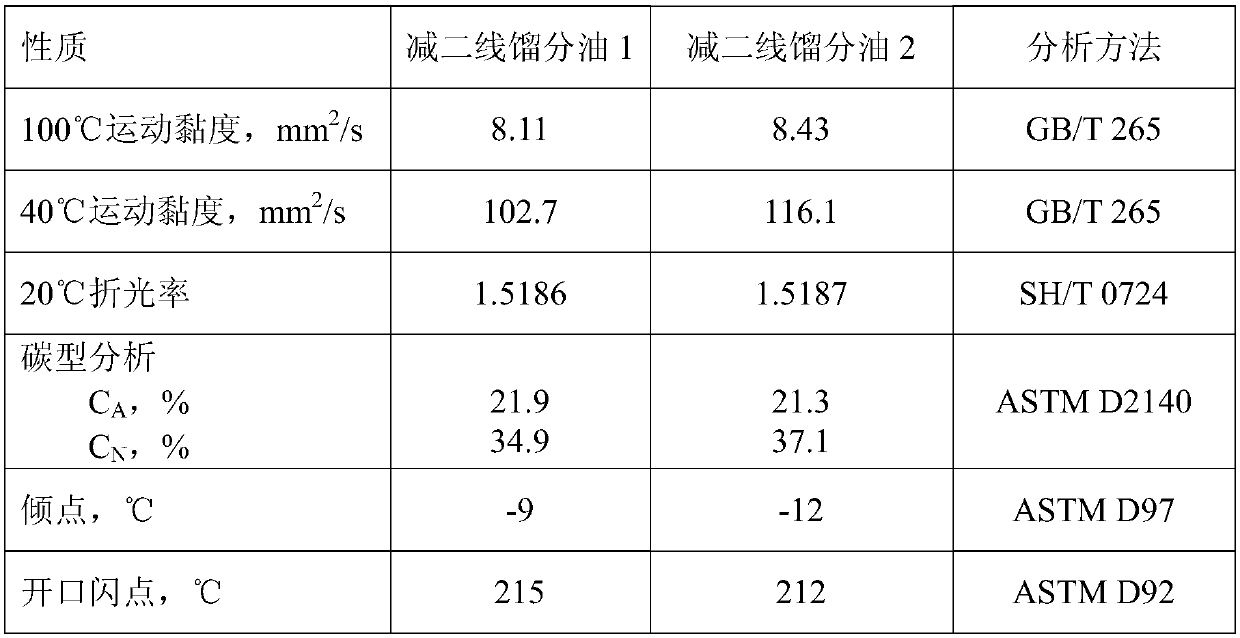

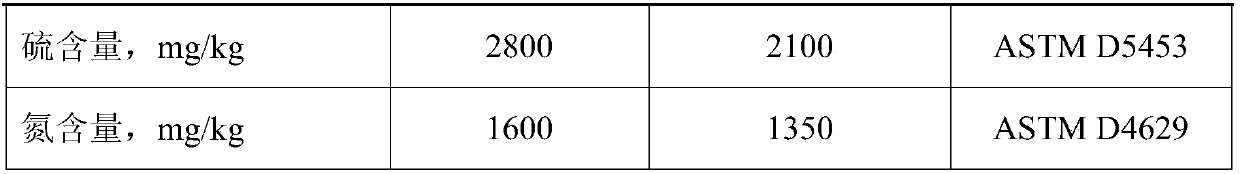

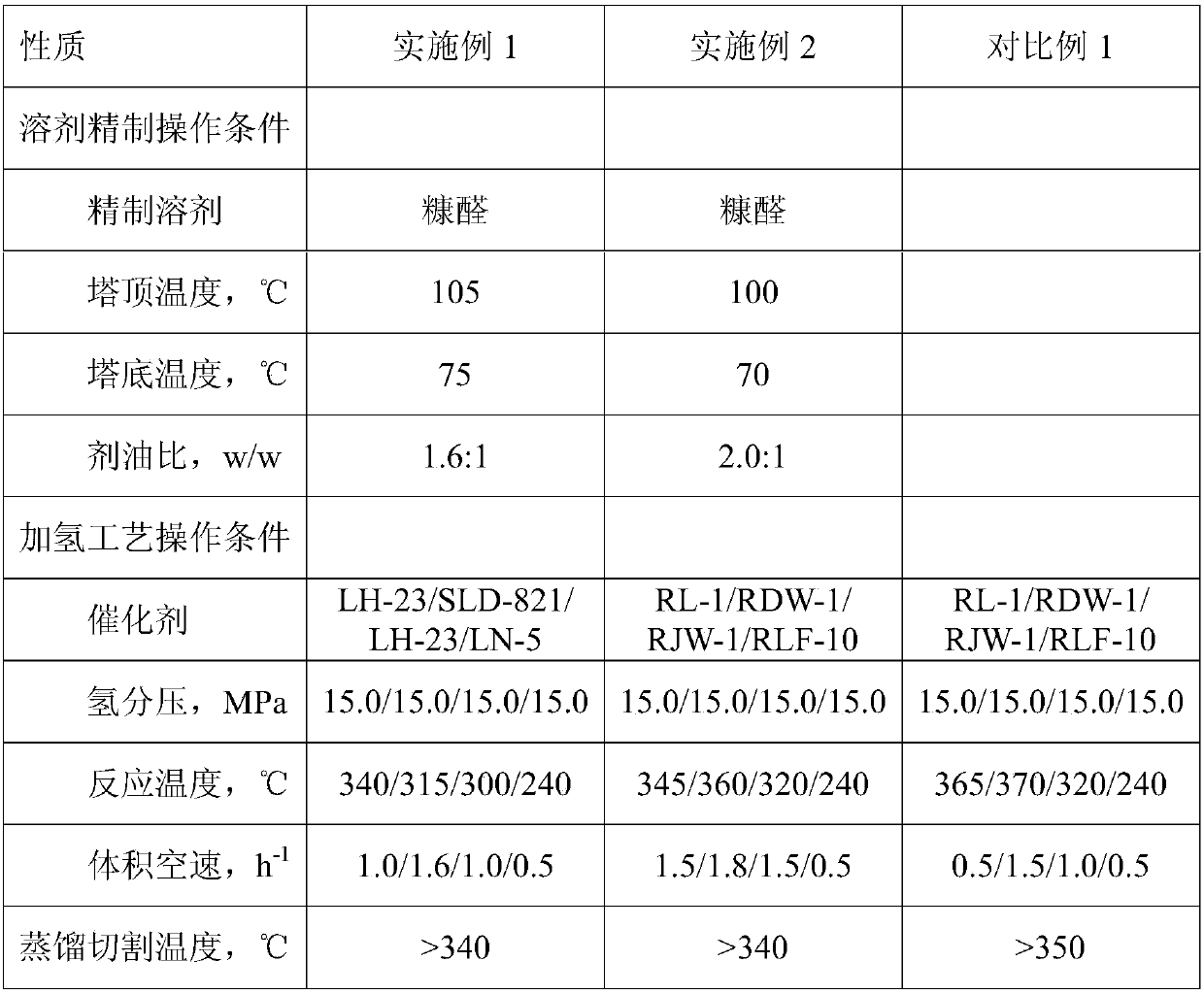

Embodiment 1

[0060] The naphthenic crude oil minus the second-line distillate 1 produced by the atmospheric and vacuum unit is used as raw material (the properties of the raw material are shown in Table 1), and the refined hydrocarbon oil is obtained by solvent refining process. The refined solvent is furfural, and the refined hydrocarbon oil is used as the raw material of the hydrogenation unit , the refined hydrocarbon oil passes through the hydrotreating section, the catalytic dewaxing section, the hydrofining section and the deeply saturated aromatics section in turn, and then is cut by distillation, and the fraction higher than 340°C is collected as PS white oil. Among them, the hydrogenation section adopts LH-23 hydrogenation catalyst, the reaction temperature is 340°C, the hydrogen partial pressure is 15.0MPa, and the space velocity is 1.0h -1 , the volume ratio of hydrogen to oil is 1000:1; the catalytic dewaxing section adopts SLD-821 isomerization dewaxing catalyst, the reaction t...

Embodiment 2

[0064] The naphthenic crude oil minus the second-line distillate 2 produced by the atmospheric and vacuum unit is used as raw material (the properties of the raw material are shown in Table 1), and the refined hydrocarbon oil is obtained by using a solvent refining process. The refined solvent is furfural, and the refined hydrocarbon oil is used as the raw material of the hydrogenation unit , the refined hydrocarbon oil passes through the hydrotreating section, the catalytic dewaxing section, the hydrofining section and the deeply saturated aromatics section in turn, and then is cut by distillation, and the fraction higher than 340°C is collected as PS white oil. Among them, the hydrogenation section adopts RL-1 hydrogenation catalyst, the reaction temperature is 345°C, the hydrogen partial pressure is 15.0MPa, and the space velocity is 1.5h -1 , the volume ratio of hydrogen to oil is 1000:1; the catalytic dewaxing section adopts RDW-1 hydrogen decondensation catalyst, the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com