Control method of ethylene carbonate synthesis process

A technology for ethylene carbonate and synthesis process, which is applied in the control field of ethylene carbonate synthesis process, and can solve the problems of low product purity, reduced circulation amount, complexity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

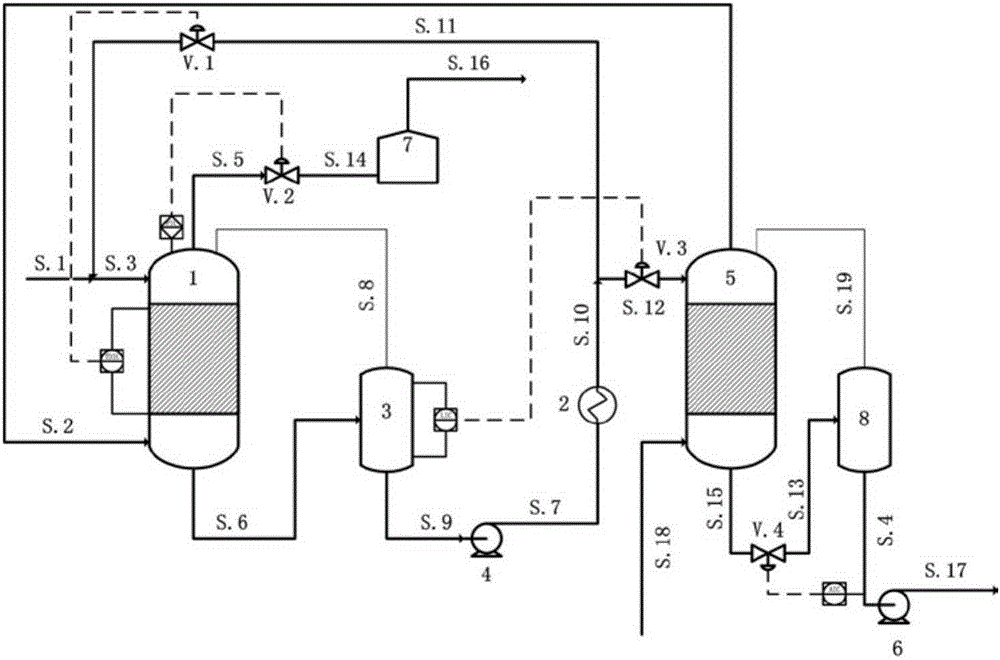

[0044] Combine below figure 1 Example 1 will be described.

[0045] process such as figure 1 Shown, the flow rate of ethylene oxide feed (S.1) is 100kg / h, enters the top of one-stage synthesis reactor (1), and the flow rate of carbon dioxide feed (S.2) is 100kg / h, by the second stage synthesis reaction Add at the bottom of the device (5). The pressure of the first-stage synthesis reactor is controlled at 2.5MPa by the pressure control valve of the top gas phase pipeline. The gas phase space between the reactor and the circulation pump buffer tank (3) is connected by a balance pipe. Controlled by the control valve, the temperature rise in the reactor is controlled at about 20°C by the flow control valve of the circulating material. The reactor inlet temperature was 80°C. When the system is stable, the temperature of the liquid phase stream (S.6) obtained at the bottom of the first section of synthesis reactor is about 100°C, and enters the circulation pump buffer tank (3)...

Embodiment 2

[0050] Combine below figure 1 Example 2 will be described.

[0051] process such as figure 1 Shown, the flow rate of ethylene oxide feed (S.1) is 100kg / h, enters the top of one-stage synthesis reactor (1), and the flow rate of carbon dioxide feed (S.2) is 100kg / h, by the second stage synthesis reaction Add at the bottom of the device (5). The pressure of the first-stage synthesis reactor is controlled at 1.5MPa by the pressure control valve of the top gas phase pipeline. The gas phase space between the reactor and the circulation pump buffer tank (3) is connected by a balance pipe. The control valve controls the temperature of the lower layer of the catalyst bed in the reactor to be controlled at about 100°C by the flow control valve of the circulating material. The reactor inlet temperature was 80°C. When the system is stable, the temperature of the liquid phase stream (S.6) obtained at the bottom of the first section of synthesis reactor is about 100°C, and enters the ...

Embodiment 3

[0056] Combine below figure 1 Example 3 will be described.

[0057] process such as figure 1 Shown, the flow rate of ethylene oxide feed (S.1) is 100kg / h, enters the top of one-stage synthesis reactor (1), and the flow rate of carbon dioxide feed (S.2) is 100kg / h, by the second stage synthesis reaction Add at the bottom of the device (5). The pressure of the first-stage synthesis reactor is controlled at 3.0MPa by the pressure control valve of the gas phase pipeline at the top, and the gas phase space between the reactor and the buffer tank (3) of the circulation pump is connected by a balance pipe, and the liquid level of the buffer tank of the circulation pump is from the first stage to the liquid phase production flow of the second stage Controlled by the control valve, the temperature of the lower layer of the catalyst bed in the reactor is controlled at about 115°C by the flow control valve of the circulating material. The reactor inlet temperature was 90°C. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com