High precision adjustable automatic constant temperature test system for pump

A constant temperature test, high-precision technology, applied in the direction of temperature control using electric mode, auxiliary controller with auxiliary heating device, etc., can solve the problem of heat transfer speed, low strength, unfavorable test medium for a long time, and uncontrollable speed To achieve the effect of ensuring temperature rise and cooling compensation, facilitating the rapid dissipation of heat, and ensuring that the temperature control is not excessive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

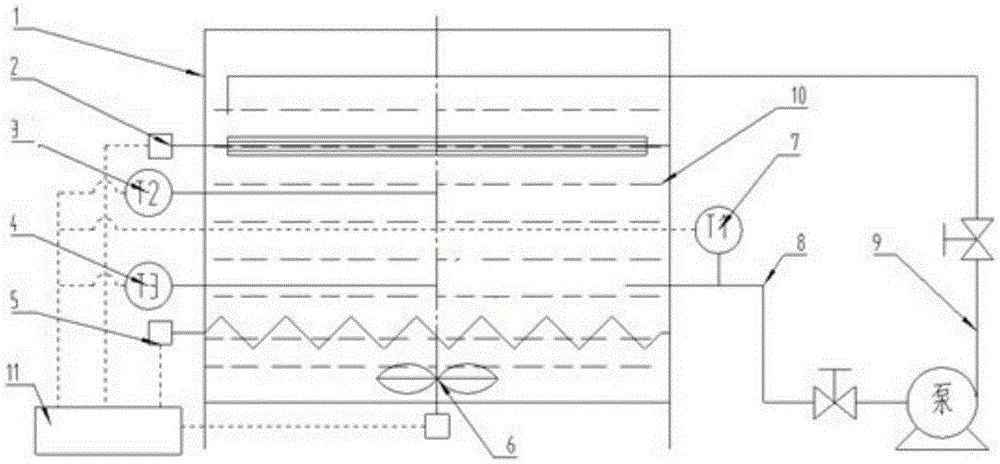

[0045] Such asfigure 1 As shown, a high-precision adjustable automatic constant temperature test system for pumps includes a liquid storage tank 1, a test medium 10, a temperature rise device 5, a cooling device 2, a forced convection device 6, a temperature measurement and analysis system, and a temperature acquisition and control system. 11. The pump inlet pipeline 8 and the pump outlet pipeline 9, the test medium 10 is stored in the liquid storage tank 1, the temperature rise device 5, the cooling device 2, the forced convection device 6, the temperature sensor, the pump inlet pipeline 8 and the pump outlet The pipelines 9 are all installed on the liquid storage tank 1, and the temperature rise device 5 is installed on the inner lower part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com