High-modulus glass fiber composition

A glass fiber and composition technology, which is applied in the field of national defense and military industry, can solve the problems of high liquidus temperature of glass fiber, unsatisfactory glass fiber modulus, difficult production, etc., and can reduce the liquidus temperature and mechanical properties, improve the Glass melting performance, effect of improving melting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

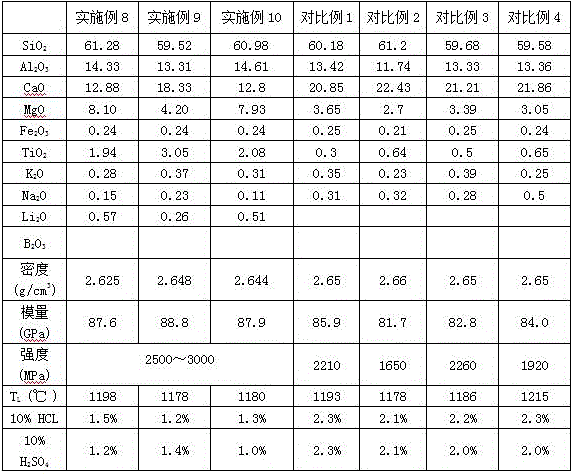

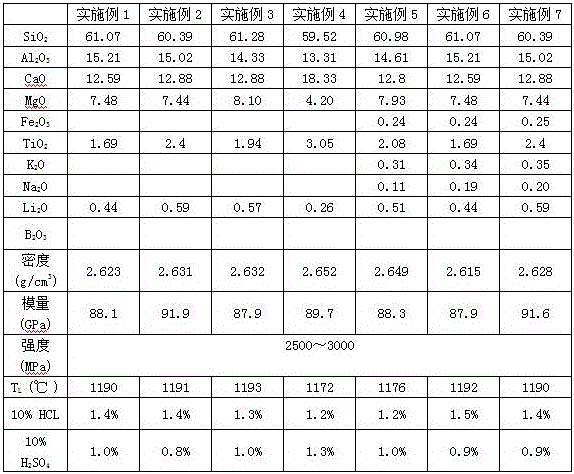

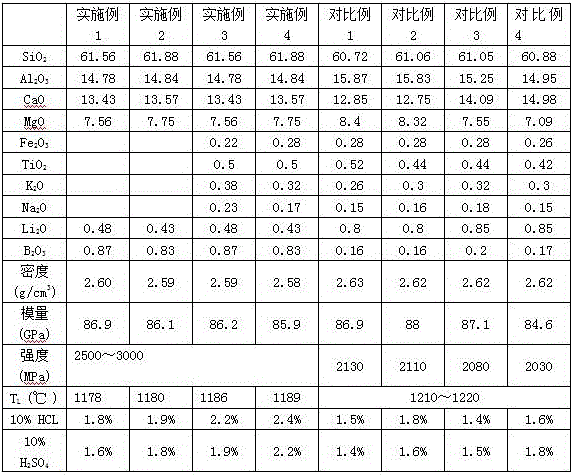

[0031] Table 1 is an example of the high modulus glass fiber composition of the technical solution 1 of the present invention.

[0032] According to the high modulus glass fiber composition shown in Table 1, the glass composition contains the following components, and the content of each component is expressed as follows in parts by weight: SiO 2 59~62 copies; Al 2 o 3 13~15.5 parts; CaO 12.5~18.5 parts; MgO 4~8.5 parts; TiO 2 1.5 to 4 parts and Li 2 O 0.1 to 0.6 parts.

[0033] During specific implementation, the glass fiber composition also includes the following components, and the content of each component is expressed as follows in parts by weight: Fe 2 o 3 0.2~0.3 parts; K 2 O 0.2~0.4 parts and Na 2 O 0.1 to 0.4 parts.

[0034] Table 1

[0035]

[0036] Table 1 (continued)

[0037]

[0038] The method for preparing glass fiber from the high-modulus glass fiber composition of the technical solution 1 of the present invention, the raw materials used mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com