Dielectric material of glass-ceramics with high energy storage density and preparation method

A technology with high energy storage density and dielectric material, applied in inorganic insulators and other directions, can solve the problems of high dielectric loss and unfavorable electrical resistance of glass-ceramic, and achieve low dielectric loss, fine grains, and accelerated diffusion speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

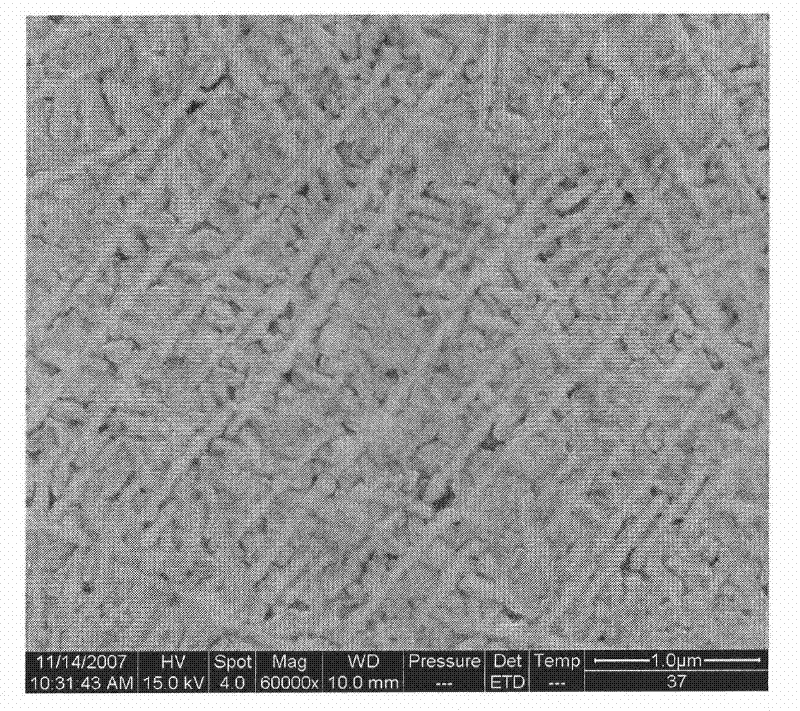

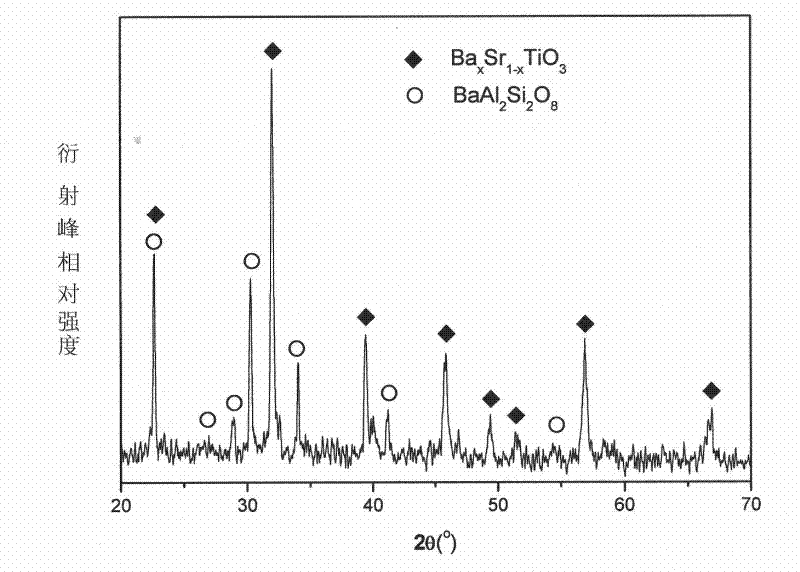

Embodiment 1

[0036] A high energy storage density glass-ceramic dielectric material, the main components of the glass-ceramic dielectric material are BaO, SrO, TiO 2 , SiO 2 And Al 2 O 3 , Its composition doped with AlF 3 And MnO 2 , The molar ratio of main components is BaO:SrO:TiO 2 : SiO 2 : Al 2 O 3 = 0.2936: 0.0734: 0.305: 0.212: 0.086, doped with AlF 3 The number of moles accounts for 4% of the total number of moles of the component (the component is composed of the main component and the doped component), doped with MnO 2 The number of moles accounts for 1% of the total number of moles of the component (the component is composed of the main component and the doped component).

[0037] A method for preparing a high energy storage density glass-ceramic dielectric material is as follows:

[0038] (1) Using BaCO with a purity greater than 99% 3 , SrCO 3 , TiO 2 , SiO 2 , Al 2 O 3 , AlF 3 And MnO 2 As starting material, according to the main components BaO, SrO, TiO 2 , SiO 2 And Al 2 O 3 The m...

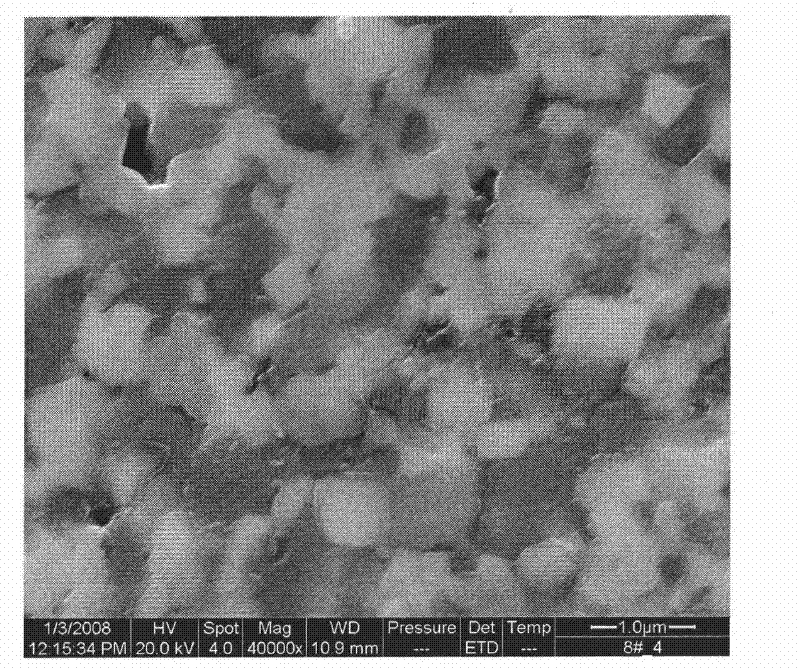

Embodiment 2

[0047] A high energy storage density glass-ceramic dielectric material, the main components of the glass-ceramic dielectric material are BaO, SrO, TiO 2 , SiO 2 And Al 2 O 3 , Its composition doped with AlF 3 And MnO 2 , The molar ratio of main components is BaO:SrO:TiO 2 : SiO 2 : Al 2 O 3 = 0.2800: 0.0820: 0.3150: 0.2200: 0.1060, doped with AlF 3 The number of moles accounts for 6% of the total number of moles of components, doped with MnO 2 The number of moles accounts for 0.4% of the total number of moles of components.

[0048] A method for preparing a high energy storage density glass-ceramic dielectric material is as follows:

[0049] (1) Using BaCO with a purity greater than 99% 3 , SrCO 3 , TiO 2 , SiO 2 , Al 2 O 3 , AlF 3 And MnO 2 As starting material, according to the main components BaO, SrO, TiO 2 , SiO 2 And Al 2 O 3 The molar ratio is BaO:SrO:TiO 2 : SiO 2 : Al 2 O 3 = 0.2800: 0.0820: 0.3150: 0.2200: 0.1060, doped with AlF 3 The number of moles accounts for 6% of the ...

Embodiment 3

[0055] A high energy storage density glass-ceramic dielectric material, the main components of the glass-ceramic dielectric material are BaO, SrO, TiO 2 , SiO 2 And Al 2 O 3 , Its composition doped with AlF 3 And MnO 2 , The molar ratio of main components is BaO:SrO:TiO 2 : SiO 2 : Al 2 O 3 =0.3301:0.0522:0.3150:0.2300:0.0800, doped with AlF 3 The number of moles accounts for 7% of the total number of moles of the components, doped with MnO 2 The number of moles accounts for 0.6% of the total number of moles of components.

[0056] A method for preparing a high energy storage density glass-ceramic dielectric material is as follows:

[0057] (1) Using BaCO with a purity greater than 99% 3 , SrCO 3 , TiO 2 , SiO 2 , Al 2 O 3 , AlF 3 And MnO 2 As starting material, according to the main components BaO, SrO, TiO 2 , SiO 2 And Al 2 O 3 The molar ratio is BaO:SrO:TiO 2 : SiO 2 : Al 2 O 3 =0.3301:0.0522:0.3150:0.2300:0.0800, doped with AlF 3 The number of moles accounts for 7% of the total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com