Preparation method of silica gel for polyolefin catalyst carrier

A polyolefin catalyst, silica gel technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor quality stability of silica gel products, difficult to control process repeatability, complex process, etc. Process repeatability, improved pore volume, simple process control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

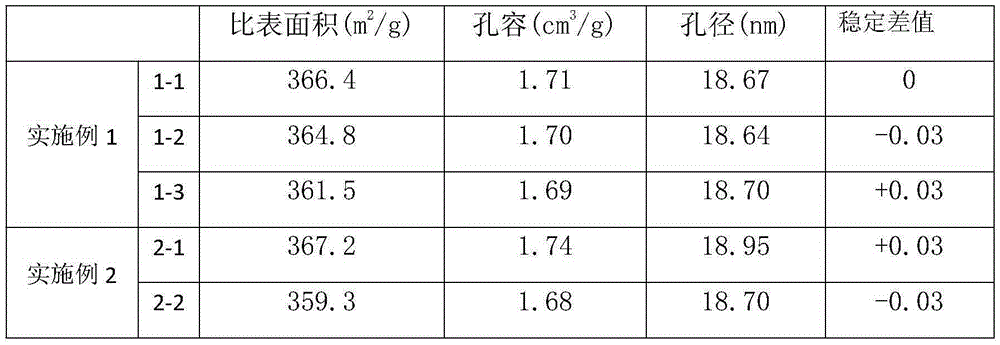

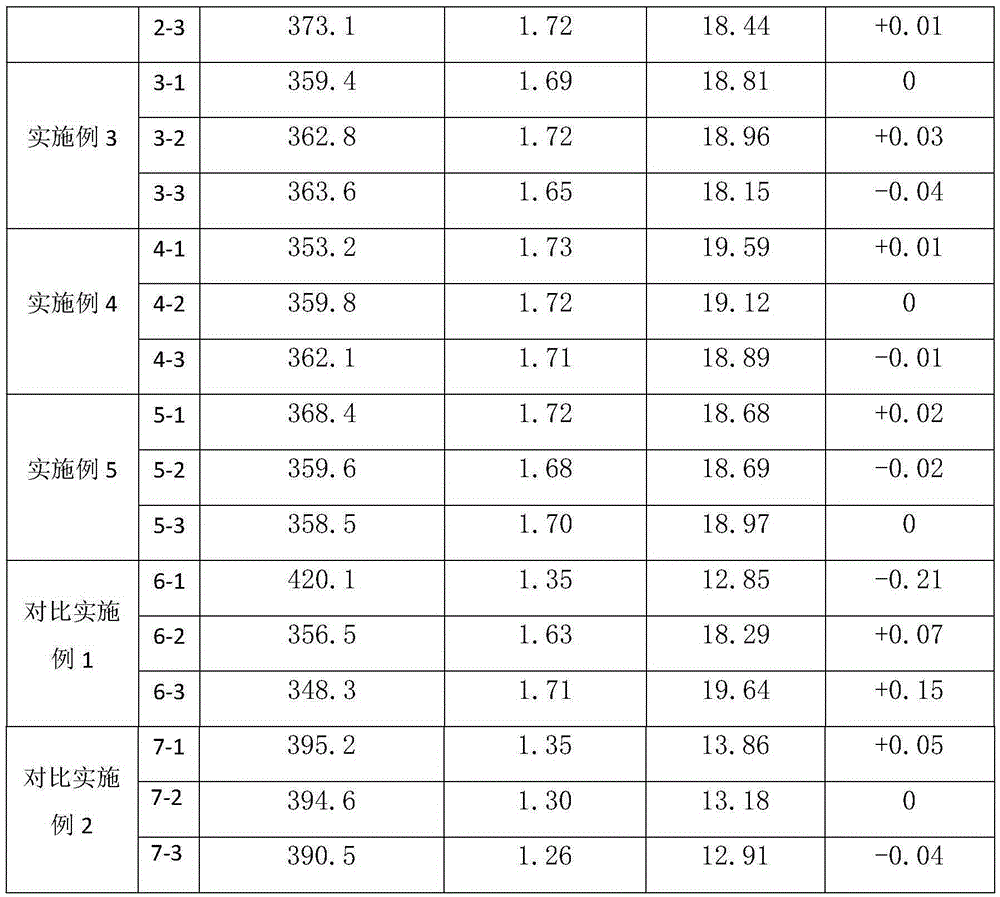

Embodiment 1

[0030] Add 4.0g of alkaline silica sol into the reaction kettle, turn on the stirring at 18r / min, slowly raise the temperature to 50°C, add 1.0mol / L silicate and 1.5mol / L dilute sulfuric acid at 3ml / min in parallel, when When the pH value of the reaction solution reaches 6, distilled water is added to disperse the sol-gel system thoroughly; 2.0mol / L silicate and 1.5mol / L dilute sulfuric acid are added in parallel flow at 6ml / min, when the pH value of the reaction solution is 12, Stop adding the mixed solution, and react at a constant temperature for 2 hours; slowly raise the temperature of the reaction solution to 90°C, and react at a constant temperature for 3 hours; quickly add 1.5mol / L dilute sulfuric acid, when the pH value of the reaction solution is 3, stop adding dilute sulfuric acid, and react at a constant temperature for 1 Hours; remove the heating device, slowly cool to room temperature, then wash with distilled water three times, dry at 335°C, and activate at 600°C ...

Embodiment 2

[0032] The preparation process is the same as in Example 1, except that 3.0 g of silica sol is added, and other conditions are the same as in Example 1. The three repeated tests are 2-1, 2-2, 2-3, and the test results of silica gel physical properties are shown in Table 1.

Embodiment 3

[0034] 1.0mol / L silicate and 1.5mol / L dilute sulfuric acid were added in parallel at 5ml / min. When the pH value of the reaction solution reached 6, distilled water was added to completely disperse the sol-gel system. Other conditions were the same as in Example 1. The three repeated tests are 3-1, 3-2, 3-3, and the test results of silica gel are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com