Toughened epoxy-resin-based glass fiber composite material and preparation method thereof

A tough epoxy resin and composite material technology, applied in chemical instruments and methods, synthetic resin layered products, glass/slag layered products, etc., can solve the problems of low impact strength, reduce the tensile strength of composite materials, etc. Strong impact resistance, avoids the reduction of tensile strength, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

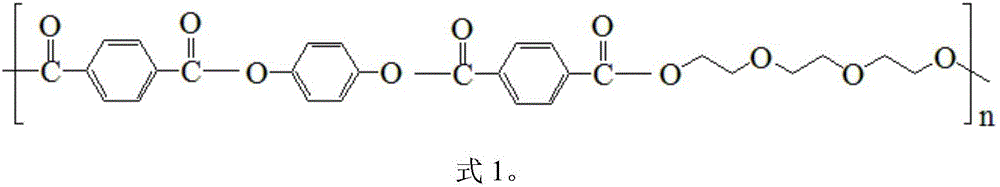

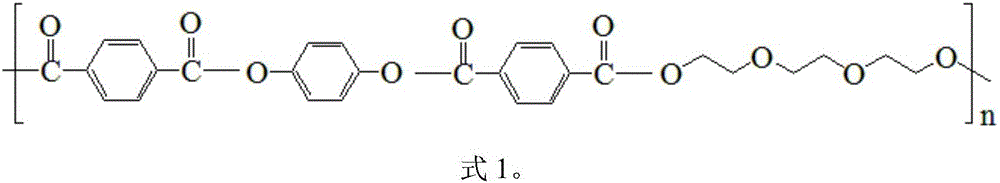

[0041] A toughened epoxy resin-based fiberglass composite material comprising five composite material units, each composite material unit comprising an epoxy resin substrate layer and a glass fiber cloth placed on the epoxy resin substrate layer Lay-up, between every two composite material units, the epoxy resin substrate layer of one composite material unit is closely attached to the glass fiber cloth layer of the other composite material unit to superimpose to form the toughened epoxy resin-based glass fiber Composite material, the epoxy resin substrate includes the following components in parts by mass: 75 parts of epoxy resin EP-51, 25 parts of 593 curing agent and 8 parts of the liquid crystal material of the above formula 1.

[0042] A preparation method of a toughened epoxy resin-based glass fiber composite material is prepared by the following method:

[0043] 1) Weigh the following components by mass: 75 parts of epoxy resin EP-51, 25 parts of 593 curing agent and 8 p...

Embodiment 2

[0049] A toughened epoxy resin-based fiberglass composite material comprising five composite material units, each composite material unit comprising an epoxy resin substrate layer and a glass fiber cloth placed on the epoxy resin substrate layer Lay-up, between every two composite material units, the epoxy resin substrate layer of one composite material unit is closely attached to the glass fiber cloth layer of the other composite material unit to superimpose to form the toughened epoxy resin-based glass fiber Composite material, the epoxy resin substrate includes the following components in parts by mass: 80 parts of epoxy resin EP-51, 20 parts of DDM and 3 parts of the liquid crystal material of the above formula 1.

[0050] A preparation method of a toughened epoxy resin-based glass fiber composite material is prepared by the following method:

[0051] 1) Weigh the following components by mass: 80 parts of epoxy resin EP-51, 20 parts of DDM and 3 parts of the liquid crystal...

Embodiment 3

[0057] A toughened epoxy resin-based fiberglass composite material comprising five composite material units, each composite material unit comprising an epoxy resin substrate layer and a glass fiber cloth placed on the epoxy resin substrate layer Lay-up, between every two composite material units, the epoxy resin substrate layer of one composite material unit is closely attached to the glass fiber cloth layer of the other composite material unit to superimpose to form the toughened epoxy resin-based glass fiber Composite material, the epoxy resin substrate includes the following components in parts by mass: 70 parts of epoxy resin EP-51, 30 parts of DDM and 5 parts of the liquid crystal material of the above formula 1.

[0058] A preparation method of a toughened epoxy resin-based glass fiber composite material is prepared by the following method:

[0059] 1) Weigh the following components by mass: 70 parts of epoxy resin EP-51, 30 parts of DDM and 5 parts of the liquid crystal...

PUM

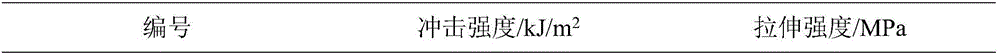

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com