Matching welding consumables for fgb method high-efficiency submerged arc welding

A technology of submerged arc welding and welding materials, applied in welding/cutting medium/material, welding equipment, welding medium and other directions, can solve the problems of inability to turn the workpiece over construction, reach 3Y level, etc. Good process performance, avoiding the effect of thick slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

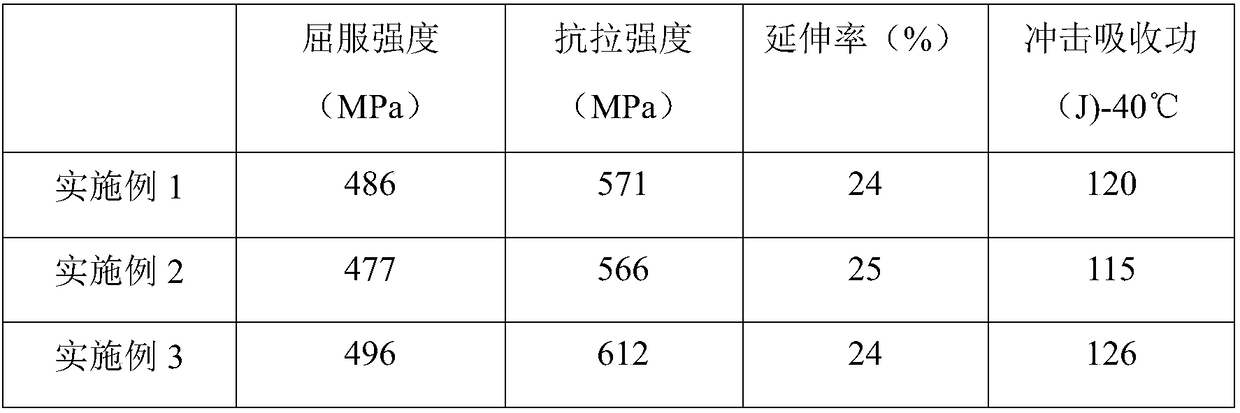

Examples

Embodiment 1

[0028] The invention provides a matching welding material for high-efficiency submerged arc welding of FGB method, including submerged arc welding wire, sintering flux, alloy powder and ceramic liner:

[0029] The sintered flux comprises the following raw materials in parts by weight: 33 parts of MgO, 6 parts of CaO, 10 parts of CaF 2 , 22 Al 2 o 3 , 25 parts of SiO 2 , 2 copies of K 2 O, 1 part of Na 2 O and 1 part of CeO;

[0030] The alloy powder includes the following raw materials in parts by weight: 96 parts of Fe, 2 parts of Mn, 0.5 part of TiFe, 0.5 part of SiFe, 0.5 part of Ni and 0.5 part of Mo;

[0031] The ceramic liner includes the following raw materials in parts by weight: 57 parts of Al 2 o 3 , 5 parts of MgO, 34 parts of SiO 2 and 4 copies of K 2 O.

[0032]During the welding process, the single power supply double wire submerged arc welding machine of ZD5(D)-1250 produced by Weida manufacturer is selected, and the EH36 material steel plate is select...

Embodiment 2

[0035] The invention provides a matching welding material for high-efficiency submerged arc welding of FGB method, including submerged arc welding wire, sintering flux, alloy powder and ceramic liner:

[0036] The sintered flux includes the following raw materials in parts by weight: 30 parts of MgO, 5 parts of CaO, 20 parts of CaF 2 , 20 Al 2 o 3 , 20 parts of SiO 2 , 2 copies of K 2 O, 2 parts of Na 2 O and 1 part of CeO;

[0037] The alloy powder includes the following raw materials in parts by weight: 96.2 parts of Fe, 2 parts of Mn, 0.5 parts of TiFe, 1 part of SiFe, 0.2 parts of Ni and 0.1 part of Mo;

[0038] The ceramic liner comprises the following raw materials in parts by weight: 50 parts of Al 2 o 3 , 6 parts of MgO, 39 parts of SiO 2 and 5 copies of K 2 O.

[0039] During the welding process, the single power supply double wire submerged arc welding machine of ZD5(D)-1250 produced by Weida manufacturer is selected, and the EH36 material steel plate is se...

Embodiment 3

[0041] The invention provides a matching welding material for high-efficiency submerged arc welding of FGB method, including submerged arc welding wire, sintering flux, alloy powder and ceramic liner:

[0042] The sintered flux includes the following raw materials in parts by weight: 35 parts of MgO, 4 parts of CaO, 15.5 parts of CaF 2 , 18 Al 2 o 3 , 22 parts of SiO 2 , 1 copy of K 2 O, 4 parts of Na 2 O and 0.5 part of CeO;

[0043] The alloy powder includes the following raw materials in parts by weight: 95 parts of Fe, 3 parts of Mn, 0.5 parts of TiFe, 0.5 parts of SiFe, 0.5 parts of Ni and 0.5 parts of Mo;

[0044] The ceramic liner comprises the following raw materials in parts by weight: 55 parts of Al 2 o 3 , 4 parts of MgO, 35 parts of SiO 2 and 6 copies of K 2 O.

[0045] During the welding process, the single power supply double wire submerged arc welding machine of ZD5(D)-1250 produced by Weida manufacturer is selected, and the EH36 material steel plate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com