Tubular synthesis system for water-soluble polymer water treatment agent production

A water-soluble polymer, water treatment agent technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical processes, chemical/physical/physical-chemical processes, etc. Intermittent production has problems such as low production efficiency and inability to guarantee product quality, to achieve the effect of being conducive to the control of reaction temperature, high production efficiency, and maintaining stable operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

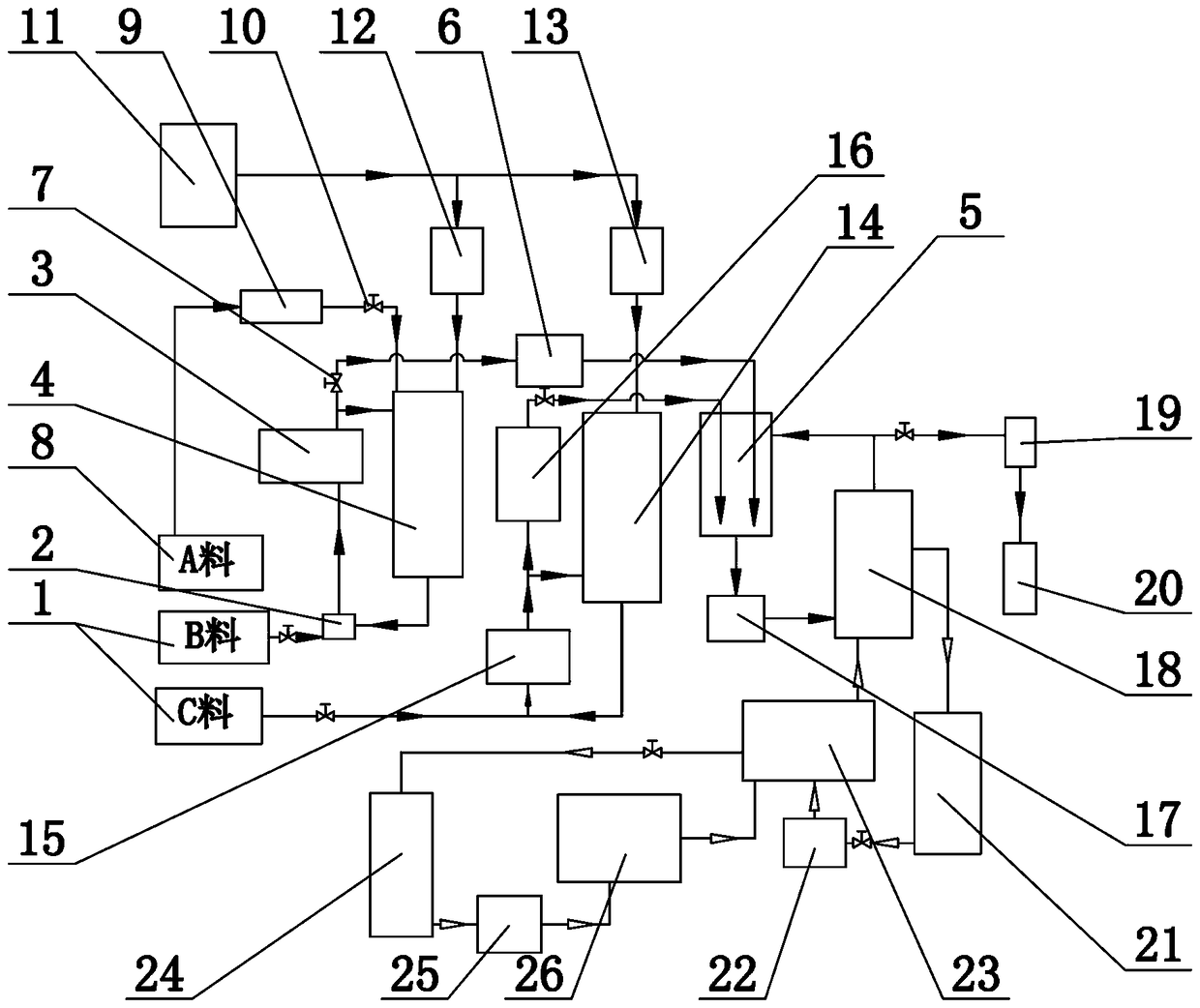

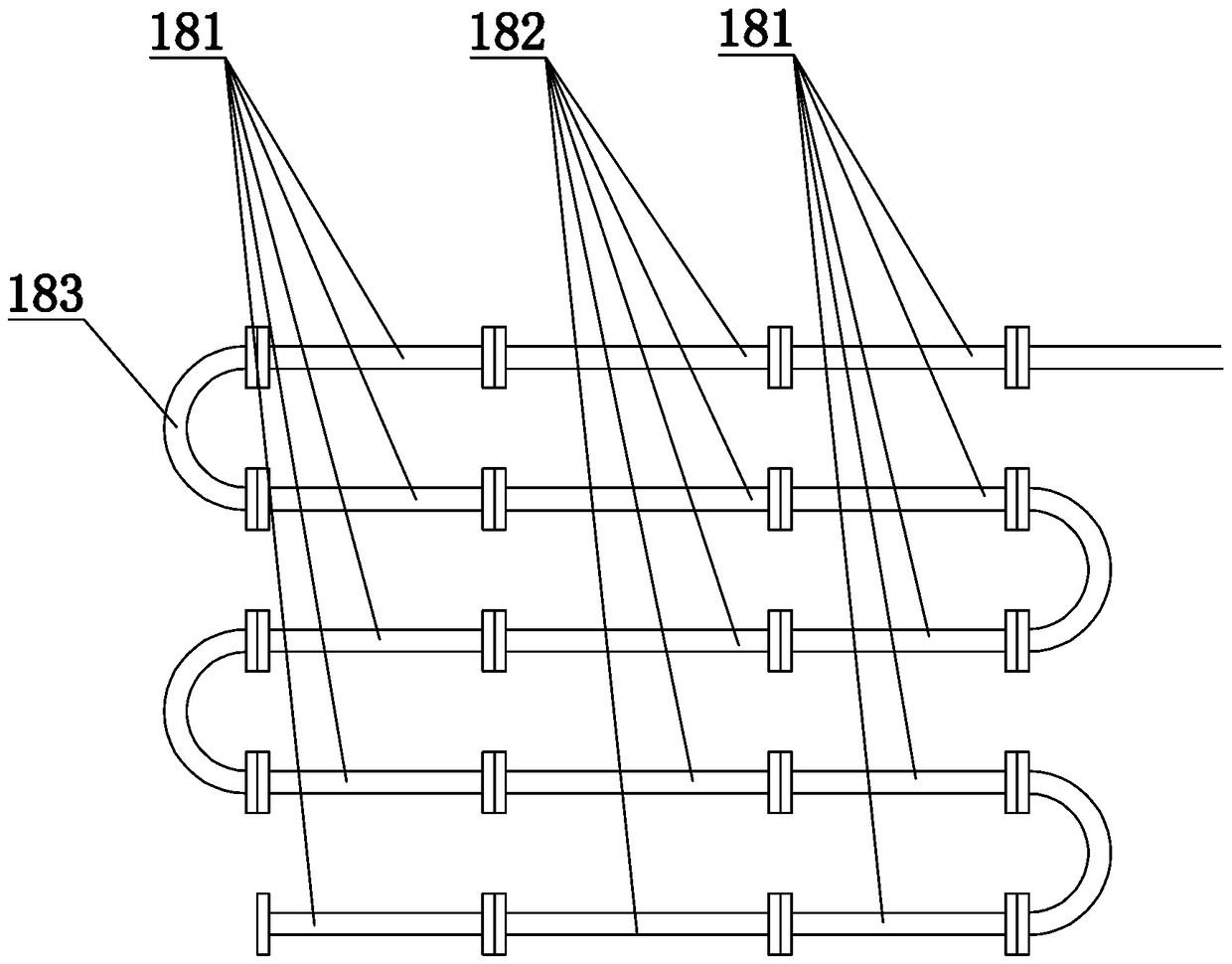

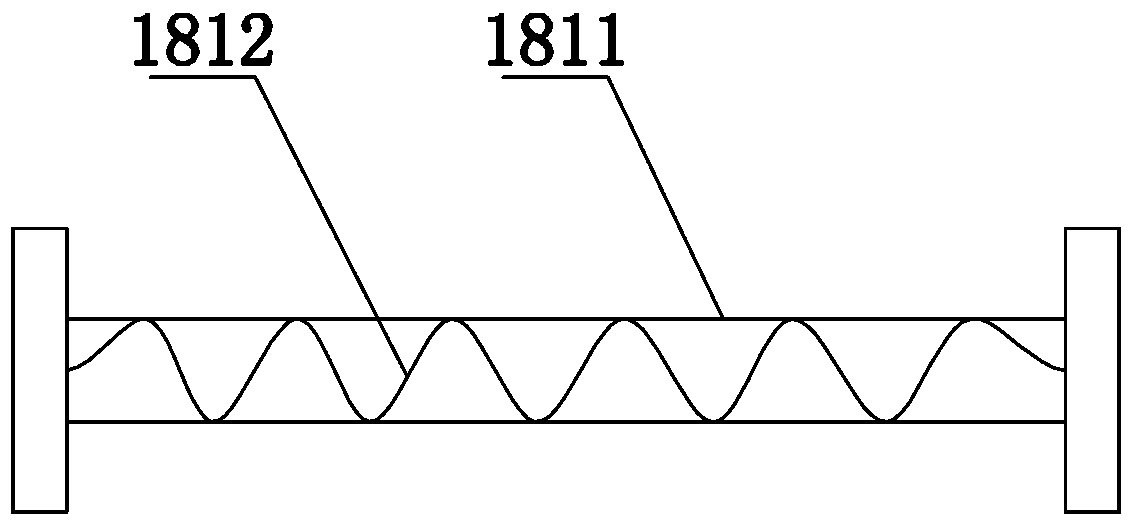

[0024] like Figure 1~4 As shown, a tubular synthesis system for the production of water-soluble polymer water treatment agents includes a plurality of raw material storage tanks 1, one of the plurality of raw material storage tanks 1 is connected to a heat exchanger I3 through a raw material pump I2, and the heat exchanger I3 It is an air-cooled heat exchanger, and the discharge port of heat exchanger I3 is respectively connected to the feed port of raw material mixing tank II4 and the mixing tank 5, and the discharge port at the lower end of the raw material mixing tank II4 is connected to the feed of raw material pump I2 mouth, the connecting pipeline between the outlet of heat exchanger I3 and the mixing tank 5 is provided with a flow meter I6 and a mixing valve I7, the initiator storage tank 8 is connected to the high-level dropping tank 9, and the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com