Hand-sewn valved outer pipe and mold and sewing method for the pipe

A technology with external tubes and valves, which is applied in the direction of valve rings and heart valves, can solve the problems of no calcification and thickening of valve leaflets, increase the financial burden of the family, increase the pain of children, etc., and achieve superior performance and durability Strong, good anti-reflux effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

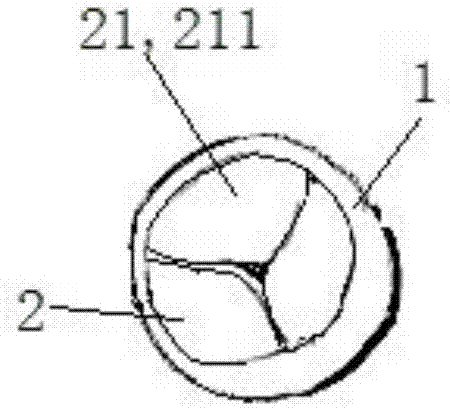

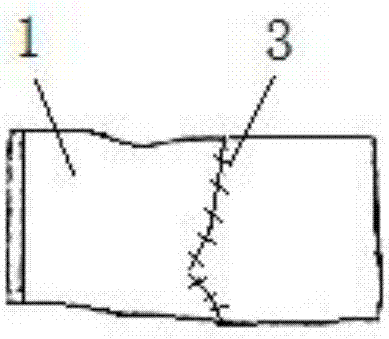

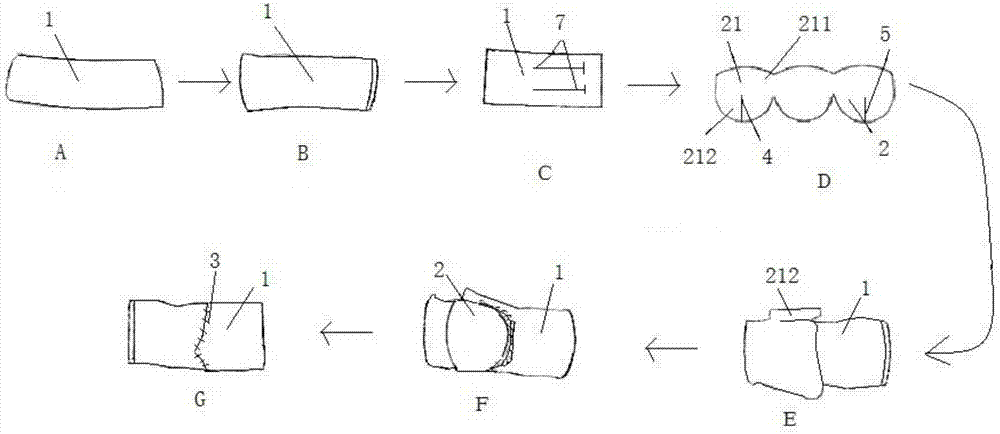

[0035] Such as figure 1 As shown, the hand-sewn valved outer tube includes an outer tube body 1 and a PTFE valve 2; the PTFE valve is composed of three U-shaped units 21 connected continuously, and each U-shaped unit 21 includes a valve part 211 and a connecting part 212 , the edge of each "U"-shaped unit 21 is sewn on the inner wall of the outer tube body 1; as image 3 As shown in the process step F and step G state, the valve portion 211 of each U-shaped unit 21 extends toward the central axis of the outer tubular body 1, and the edge portions of several valve portions 211 overlap each other freely; throughout the The 5-0 prolene line 4 from left to right and the 5-0 prole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com