A kind of heavy oil processing method

A processing method and heavy oil technology, applied in the petroleum industry, hydroprocessing process, hydrocarbon oil treatment, etc., to achieve the effects of increasing utilization, reducing dry gas and coke yield, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

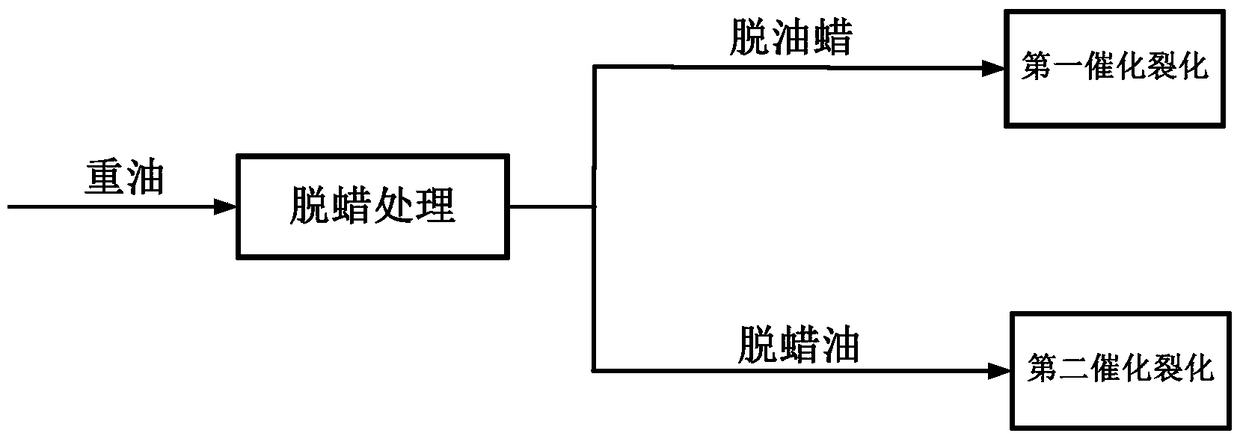

Method used

Image

Examples

Embodiment 1

[0048] This example is used to illustrate the preparation method of the separated product (ie the heavy oil defined in the present invention) in the heavy oil processing method provided by the present invention. Fill the bottom of the separation column with 30g of neutral alumina (the specific surface area is 152m 2 / gram, the pore volume is 0.213 milliliters / gram), the aluminum oxide (the massfraction of silver is 7.05 mass %, adopts silver nitrate impregnation method to prepare) of 110g loading silver in the middle of filling, upper layer filling 30g silica gel (specific surface area is 479 meters 2 / gram, the pore volume is 0.349 milliliters / gram); The lower end of the separation column is connected with the vacuum system. The total volume of the stationary phase was 150 mL. Straight-run vacuum distillate oil (referred to as VGO, Tahe crude oil is taken from the Tahe Oilfield of Sinopec Northwest Branch Company, and obtained by distillation at the real boiling point of the...

Embodiment 2

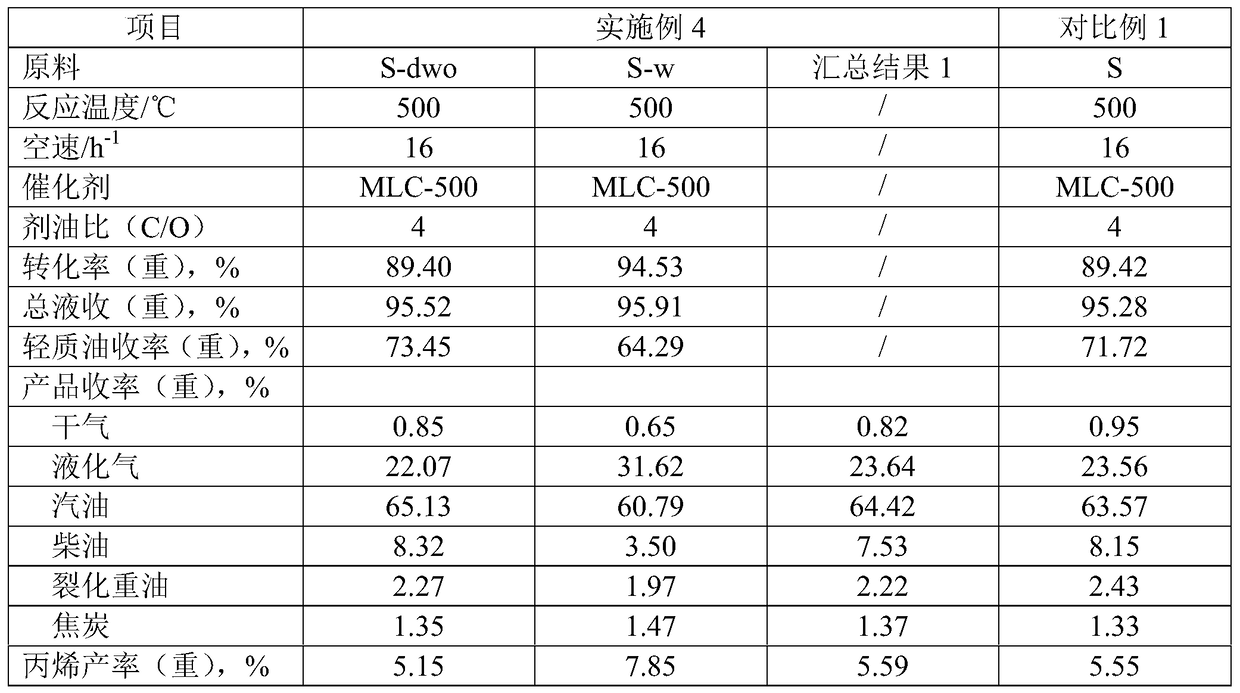

[0050] This example is used to illustrate the implementation method of heavy oil ketone-benzene dewaxing treatment in the heavy oil processing method provided by the present invention. Turn on the refrigerator and the constant temperature cold bath in advance, so that the temperature of the constant temperature cold bath reaches -22 °C. Mix methyl ethyl ketone and toluene uniformly according to the volume ratio of 3:2 and use it as a dewaxing solvent. Put a dewaxing solvent bottle containing a dewaxing solvent equivalent to twice the volume of the sample in a constant temperature cold bath at -22°C, and cool stand-by. Take by weighing 55g of the S component obtained in Example 1 in a 500mL Erlenmeyer flask, add the dewaxing solvent according to the sample: solvent=1:3 (volume), first slowly heat on a water bath to make the solution transparent and then cool to room temperature. Place the Erlenmeyer flask on the stirring device in the cold bath, turn on the stirring, and adju...

Embodiment 3

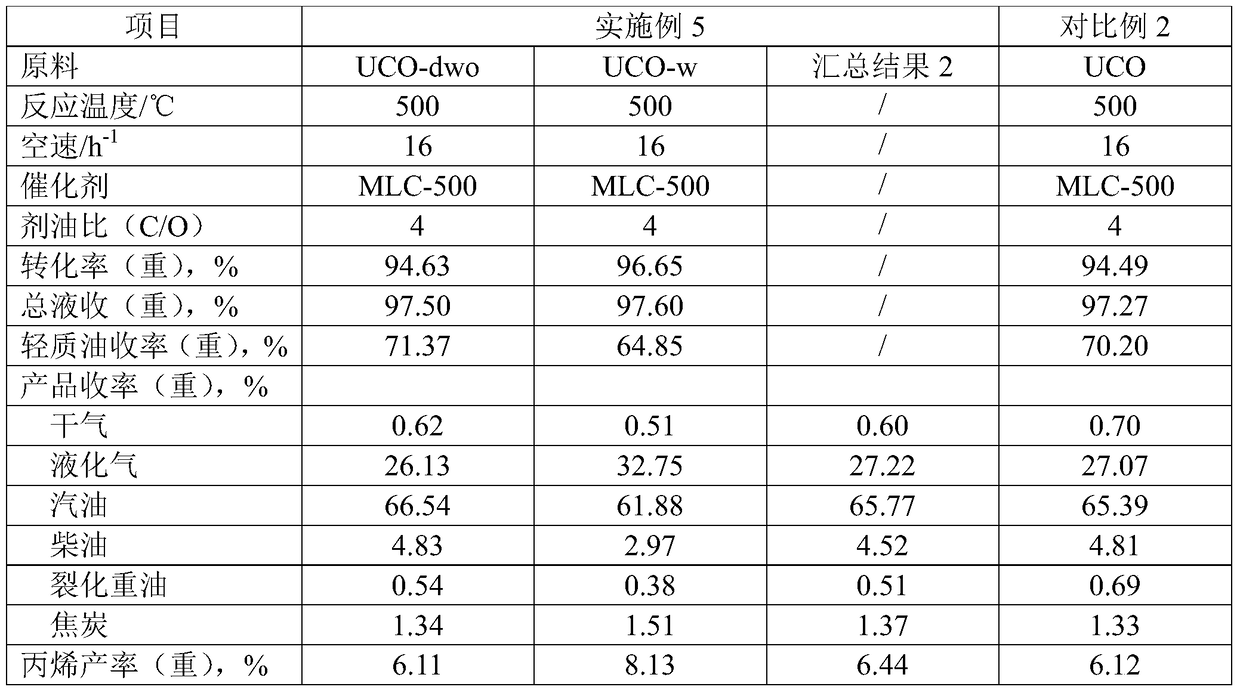

[0052] This example is used to illustrate the implementation method of ketone-benzene dewaxing treatment of hydrocracking tail oil in the heavy oil processing method provided by the present invention. Using the same method as in Example 2, the hydrocracking tail oil (Unconverted oil, referred to as UCO, the hydrocracking tail oil from the hydrocracking medium-sized unit of the Petrochemical Science Research Institute) was subjected to ketone-benzene dewaxing treatment. The dewaxed wax component (abbreviated as UCO-w) and the dewaxed oil fraction (abbreviated as UCO-dwo) obtained by dewaxing ketonebenzene were 8.98g and 45.56g, with a loss of 0.46g. The recovery rate of the dewaxing process was 99.17%. The basic physical property data of the UCO component, UCO-w component and UCO-dwo component used in the examples are listed in Table 3, and the hydrocarbon group composition is listed in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com