Assembly having two copper sheets screwed to each other and method for producing said assembly

A technology of threaded parts and copper sheets, which is applied in the direction of connecting components, threaded fasteners, and assembly of parts into assemblies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

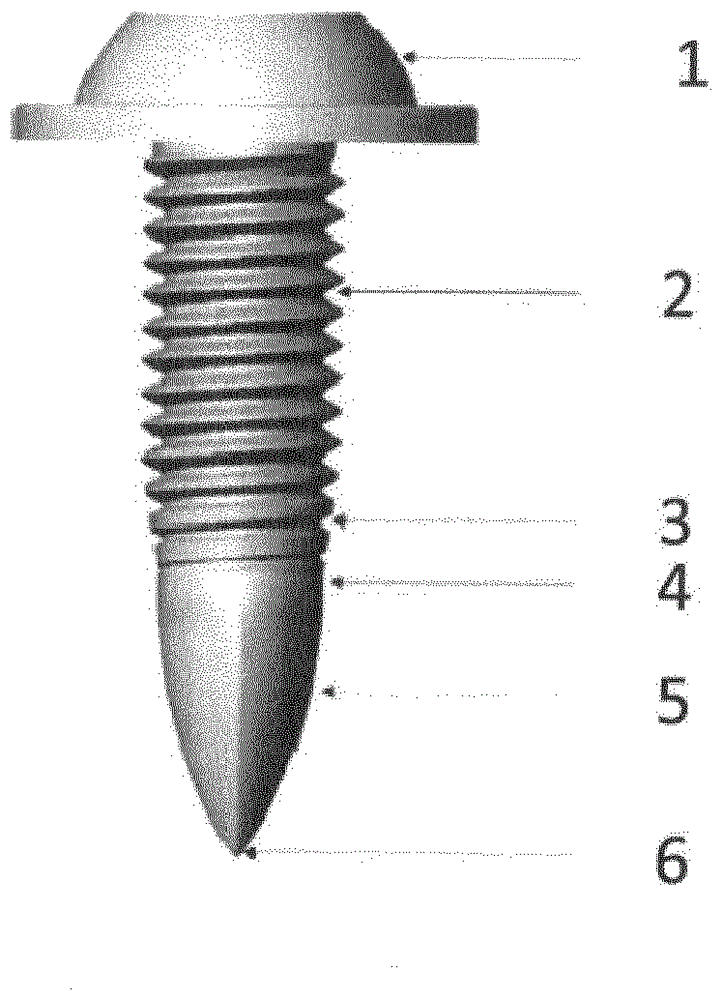

[0014] figure 1 The screw in has a screw head 1 which preferably has a recessed drive. In this context, the diameter of the screw head must be adapted to the recessed drive to be used, eg for Torx plus it is 2.5 mm. Both the screw material and the recessed drive must be designed for briefly very high rotational speeds of 4000 revolutions per minute and above.

[0015] At its end opposite the screw head 1 (advancing from the screw tip 6 to the calibration section 4 ), the screw has a flow hole forming region 5 which, in the example shown, is covered by Designed as a square tapering from calibration section 4 to the tip of the screw. After the alignment section 4 there follows a short thread-forming region 3 , adjacent to which is the carrier thread 2 .

[0016] According to the invention, a screw of this type is pressed with great force against the load-bearing support and a high rotational speed against the copper sheets to be joined, so that the screw entry point heats up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com