Semiconductor Lamp

A semiconductor and housing technology, applied in the field of semiconductor lamps, can solve the problems of glass bulbs, increase the time of hardening adhesives, and driver tension, and achieve the effects of reducing mechanical load, simplifying curling, and compact arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

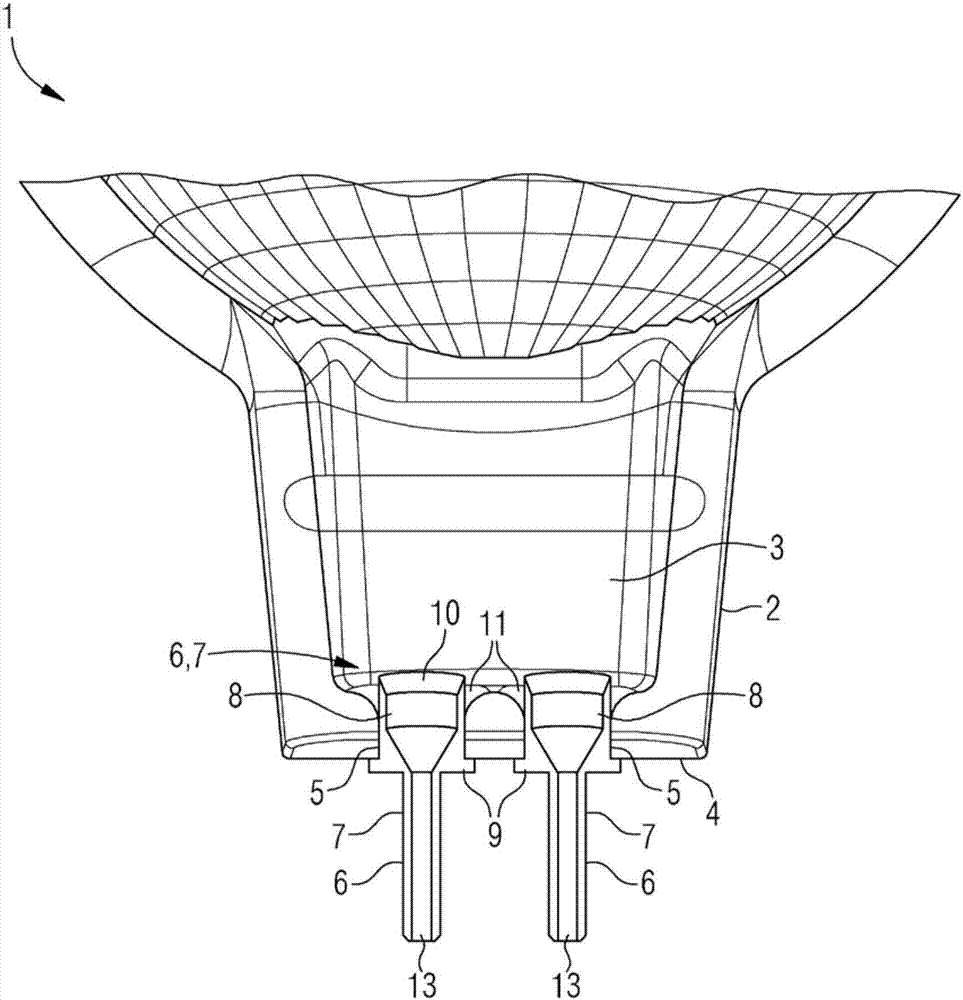

[0034] figure 1 A partial side sectional view of an LED-MR16 retrofit lamp 1 according to the invention is shown. The retrofit lamp 1 has a housing 2 in which a driver 3 is placed. Arranged on the rear end face 4 of the housing 2 are two bushings 5 into which the respective contact pin 6 is inserted. Contact pins 6 are inserted into the sleeve 5 from the outside and protrude outward from the housing 2 . Thus, a pin-base is formed there.

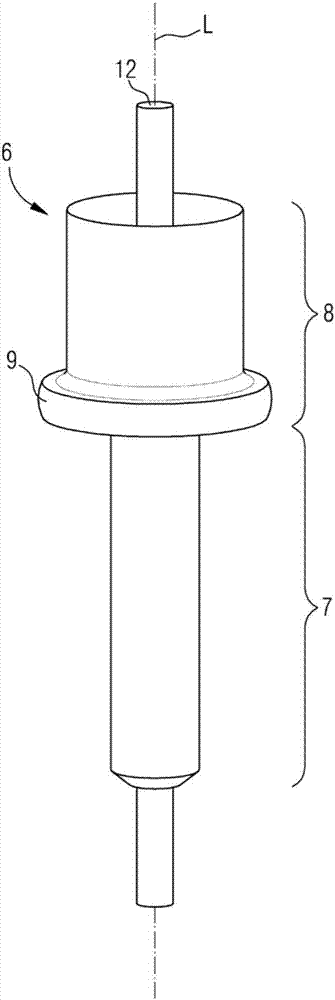

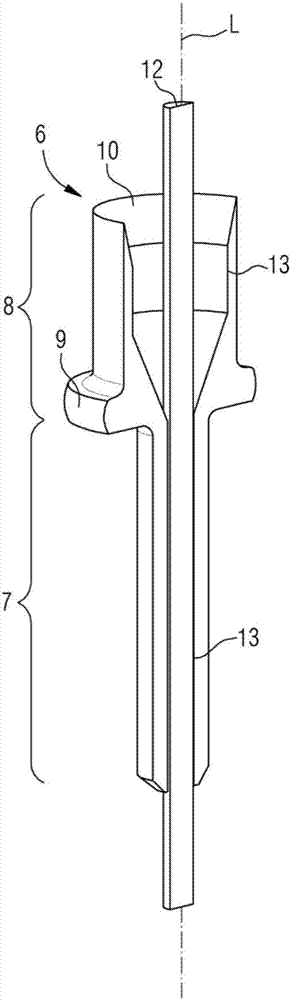

[0035] The contact pin 6 has a tubular or pin-like basic shape. This means that the outer-projecting contact section 7 has the shape of a hollow cylinder, which is compatible with conventional MR16 contact pins 102 . On the housing side, they each adjoin a widened section 8 , which is inserted into the sleeve 5 . The widened section 8 has an annular transverse projection or collar 9 in the transition to the contact section 7 . The collar 9 serves as a stop during the insertion of the respective contact pin 6 into the sleeve 5 and is on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com