Active energy ray-curable composition and film using same

An active energy ray, curable composition technology, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve problems such as film adhesion, dust adhesion, etc., to prevent adhesion, prevent adhesion, The effect of suppressing adhesion of dust and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Hereinafter, the present invention will be described more specifically using examples.

Synthetic example 1

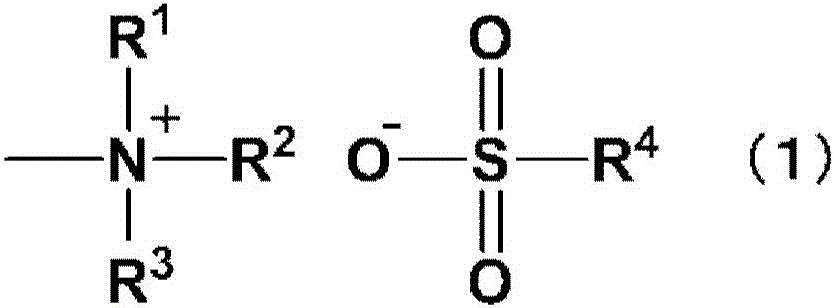

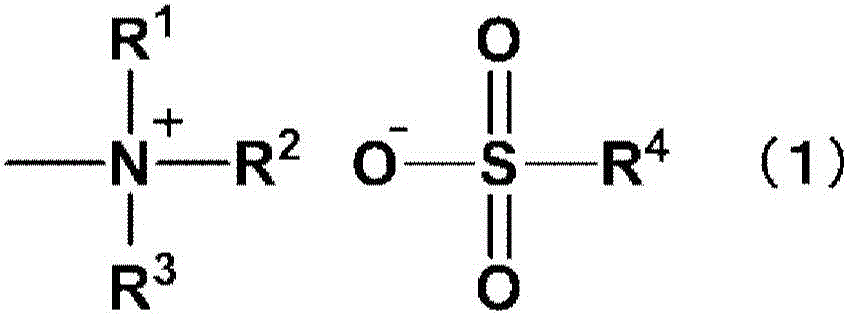

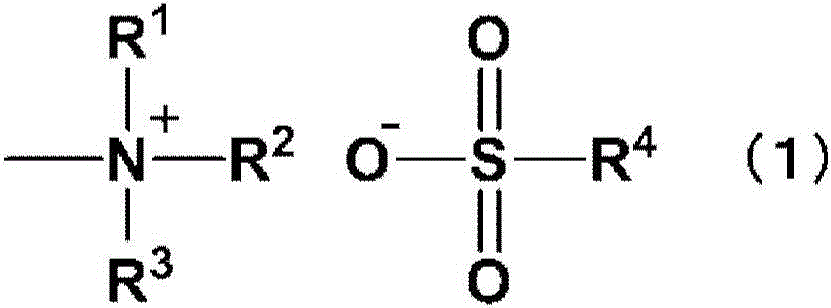

[0062] (Synthesis Example 1: Synthesis of Resin (1) with Quaternary Ammonium Salt)

[0063] Add 80% of 2-(methacryloyloxy)ethyltrimethylammonium methylphenylsulfonate (hereinafter referred to as "DMS") into a flask equipped with a stirring device, a reflux condenser, and a nitrogen introduction pipe. Mass % aqueous solution 87.5 parts by mass (70 parts by mass as DMS), methoxypolyethylene glycol methacrylate ("BLEMMER PME-4000" manufactured by NOF Corporation; number of repeating units n≈90, molecular weight 4,000) 30 parts by mass, 94.5 parts by mass of methanol, 9.45 parts by mass of propylene glycol monomethyl ether, and 1.08 parts by mass of a polymerization initiator (azobisisobutyronitrile) were reacted at 80° C. for 6 hours under a nitrogen atmosphere. Next, methanol was added and diluted, and the 45 mass % solution of the resin (1) which has a quaternary ammonium salt (sulfonate) was obtained. The weight average molecular weight of the obtained resin was 10,000.

Synthetic example 2

[0064] (Synthesis Example 2: Synthesis of Resin (2) with Quaternary Ammonium Salt)

[0065] Add 80% of 2-(methacryloyloxy)ethyltrimethylammonium methylphenylsulfonate (hereinafter referred to as "DMS") into a flask equipped with a stirring device, a reflux condenser, and a nitrogen introduction pipe. Mass % aqueous solution 87.5 parts by mass (70 parts by mass as DMS), methoxypolyethylene glycol methacrylate ("BLEMMERPME-1000" manufactured by NOF Corporation; number of repeating units n≈23, molecular weight 1,000) 30 Parts by mass, 94.5 parts by mass of methanol, 9.45 parts by mass of propylene glycol monomethyl ether, and 1.08 parts by mass of a polymerization initiator (azobisisobutyronitrile) were reacted at 80° C. for 6 hours under a nitrogen atmosphere. Next, methanol was added and diluted, and the 45 mass % solution of the resin (2) which has a quaternary ammonium salt (sulfonate) was obtained. The weight average molecular weight of the obtained resin was 10,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com