Polymer composite solid electrolyte and preparation method and application thereof

A solid electrolyte and polymer technology, applied in the field of electrochemical energy storage, can solve the problems of inability to form rechargeable and dischargeable lithium-sulfur batteries, reduce the cycle life of lithium-sulfur batteries, loss of active materials, etc. The effect of migrating channels, improving cycle life and specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of Polymer Composite Solid Electrolyte

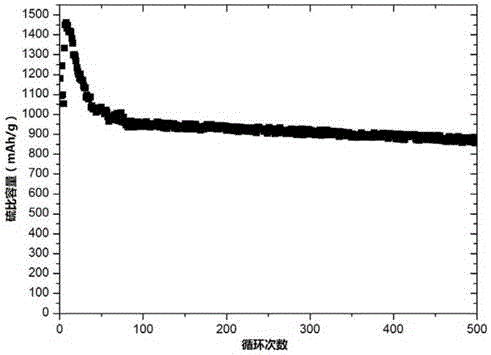

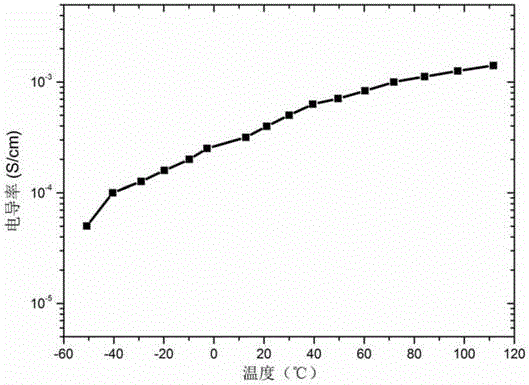

[0035] Polyphenylene sulfide (PPS) particles were mixed with lithium hydroxide (LiOH) and lithium carbonate (Li 2 CO 3 ) are mixed according to the mass ratio of 100:16:16, and then the mixture is made into a powder with a particle size of less than 1 μm by a jet mill. Dichlorodicyanoquinone (DDQ) was added to the above mixture according to the mass ratio of polyphenylene sulfide to dichlorodicyanoquinone being 100:50. The mixture was then placed in a sealed reaction vessel. Heating to 260° C. for 1 hour, and then cooling to room temperature to obtain a polymer composite solid electrolyte. The conductivity of the polymer composite solid electrolyte is shown in Table 1.

[0036] Preparation of Sulfur Composite Electrode Materials

[0037] The above-mentioned polymer composite solid electrolyte was taken out from the reactor and ground into fine particles, and then the polymer composite solid electrolyte was pulveri...

Embodiment 2

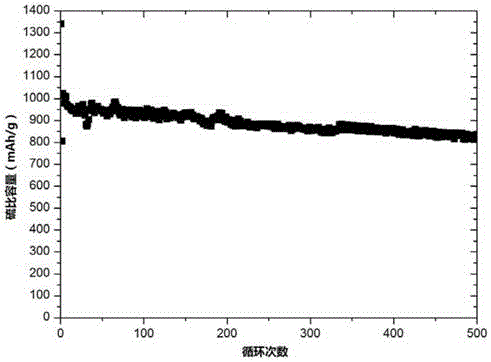

[0044] Preparation of Polymer Composite Solid Electrolyte

[0045]Polyphenylene sulfide (PPS) particles and lithium hydroxide (LiOH) were mixed according to a mass ratio of 100:30, and then the mixture was made into a powder with a particle size of less than 0.5 μm by jet milling. Chloro-p-benzoquinone was added to the above mixture according to the mass ratio of polyphenylene sulfide and tetrachloro-p-benzoquinone of 100:40, and then the mixture was placed in a sealed reaction vessel. Heated to 210° C. for 2 hours, then cooled to room temperature to obtain a polymer composite solid electrolyte. The conductivity of the polymer composite solid electrolyte is shown in Table 1.

[0046] Preparation of Sulfur Composite Electrode Material

[0047] The polymer composite solid electrolyte was taken out from the reactor and ground into fine particles, and then the polymer composite solid electrolyte was pulverized to a particle size of 2 μm by a jet mill. The polymer composite solid...

Embodiment 3

[0053] Preparation of Polymer Composite Solid Electrolyte

[0054] Polyphenylene sulfide (PPS) particles were mixed with lithium hydroxide (LiOH) at a mass ratio of 100:50, and then the mixture was made into a powder with a particle size of 0.5 μm by jet mill. Add tetracyanoquinodimethane to the above mixture according to the mass ratio of polyphenylene sulfide to tetracyanoquinodimethane of 100:60. The mixture was then placed in a sealed reaction vessel. Heating to 300°C for 0.5 hours, then cooling to room temperature to obtain a polymer composite solid electrolyte, the conductivity of the polymer composite solid electrolyte is shown in Table 1.

[0055] Preparation of Sulfur Composite Electrode Material

[0056] The above-mentioned polymer composite solid electrolyte was taken out from the reactor and ground into fine particles, and then the polymer composite solid electrolyte was pulverized to a particle size of 1 μm by a jet mill. Mix the polymer composite solid electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com