Organic electroluminescent device and preparation method thereof

An electroluminescence device and luminescence technology, which is applied in the manufacture of organic semiconductor devices, electric solid state devices, semiconductor/solid state devices, etc., can solve the problems of changing the light emitting properties of the light emitting layer, low external quantum efficiency, uncontrollable light emitting properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

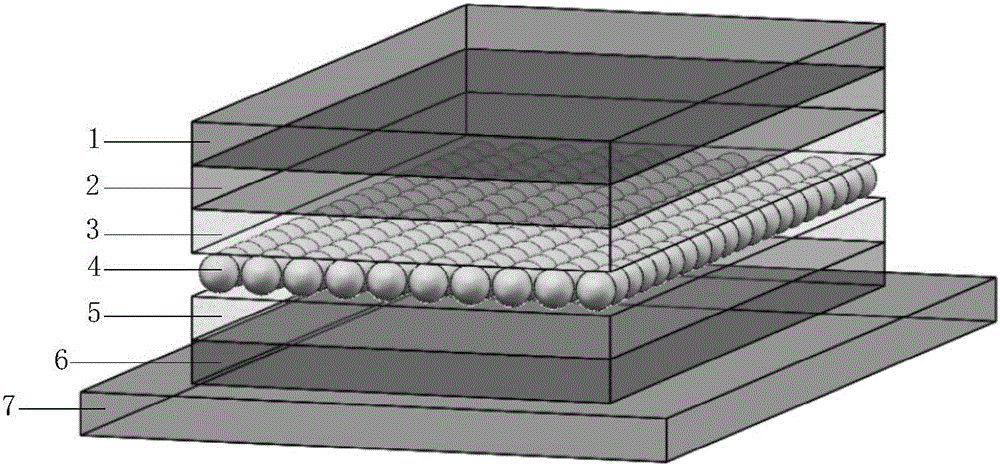

[0069] The specific embodiment part of the present invention also provides a preparation method of the organic electroluminescence device, and the preparation method includes the following steps:

[0070] (1) Spin-coat the hole injection material on the coating surface of the anode, and solidify to obtain the hole injection layer 6;

[0071] (2) Spin-coat the hole transport material on the surface of the hole injection layer 6 obtained in step (1), and solidify to obtain the hole transport layer 5;

[0072] (3) Spin-coat perovskite quantum dots on the surface of the hole transport layer 5 obtained in step (2), and solidify to obtain the light-emitting layer 4;

[0073] (4) The surface of the luminescent layer 4 obtained in step (3) is coated with an electron transport material, an electron injection material and a cathode material in sequence to obtain an organic electroluminescent device.

[0074] For better illustrating the present invention, facilitate understanding techni...

Embodiment 1

[0076] A preparation method of an organic electroluminescent device, the preparation method comprising the following steps:

[0077] (1) Spin-coat a layer of polythienothiophene doped with poly(perfluoroethylene-perfluoroethersulfonic acid) with a thickness of 20nm on the surface of the indium tin oxide coating of conductive glass. The speed of spin coating is 4000rpm, and the spin coating The time is 60s, and the spin coating is baked at 115° C. for 15 minutes to cure, and the hole injection layer 6 is obtained;

[0078] (2) The surface of the hole injection layer 6 obtained in step (1) is spin-coated with 18nm thick poly[N,N'-bis(4-butylphenyl)-N,N'-bis(phenyl)benzidine ], the spin-coating speed is 4000rpm, the spin-coating time is 35s, and the spin-coating layer is baked at 115°C for 15min to cure and solidify to obtain the hole transport layer 5;

[0079] (3) spin-coat 25nm thick perovskite type CsPbCl on the hole transport layer 5 surface that step (2) obtains 0.9 I 2....

Embodiment 2

[0083] A preparation method of an organic electroluminescent device, the preparation method comprising the following steps:

[0084] (1) Spin-coat a layer of nickel oxide with a thickness of 10nm on the surface of the fluorine-doped tin oxide coating of conductive glass, the speed of spin coating is 3000rpm, the time of spin coating is 40s, and the spin coating is baked at 100°C for 25min to solidify. A hole injection layer 6 is obtained;

[0085] (2) The surface of hole injection layer 6 obtained in step (1) is spin-coated with 5nm thick NPD, the speed of spin coating is 3000rpm, the time of spin coating is 20s, and the spin coating is baked at 100°C for 25min to cure and solidify. A hole transport layer 5 is obtained;

[0086] (3) spin-coat 10nm thick perovskite type CsPbCl on the hole transport layer 5 surface that step (2) obtains 1.1 Br 1.9 For quantum dots, the speed of spin coating is 1000rpm, the time of spin coating is 20s, and the spin coating is baked at 100°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com