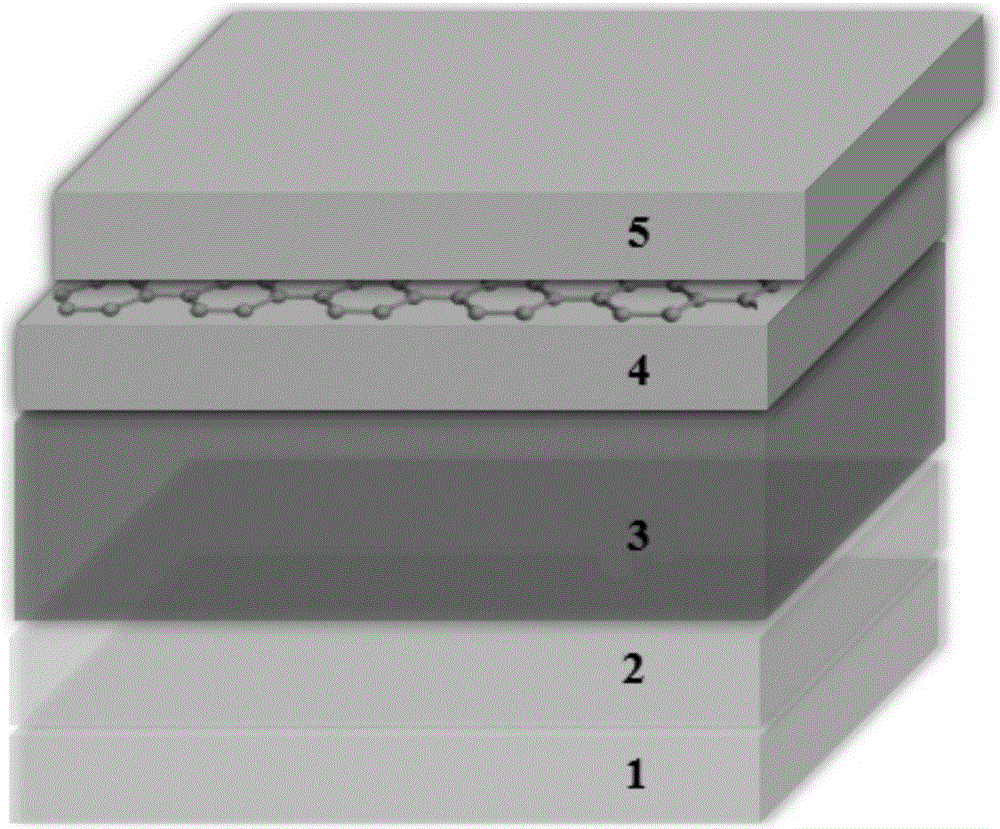

Perovskite battery having graphene barrier layer and preparation method

A perovskite battery, graphene technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of irreversible decomposition of water and oxygen, harmful doping of perovskite materials, affecting the flexibility of flexible devices, etc. Oxygen stability and thermal stability, the effect of improving water and oxygen stability, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: substrate pretreatment;

[0030] (1) Etching the FTO glass with zinc powder and dilute hydrochloric acid into a strip structure of 4mm*25mm; the dilute hydrochloric acid is prepared by mixing 1 volume mass fraction of 38% concentrated hydrochloric acid and 4 volumes of water.

[0031] (2) The etched FTO glass was ultrasonically cleaned in acetone, isopropanol, and ethanol for 5 minutes each, and dried with nitrogen.

[0032] Step 2: preparing a perovskite thin film battery substrate;

[0033] (1) Deposit a layer of TiO on the etched FTO surface by hydrothermal insulation deposition method 2 as electron transport material;

[0034] (2) The perovskite layer is spin-coated on the electron transport layer by solution spin coating, and the solution used is CH 3 NH 3 I and PbI 2 The mixed solution, the solution concentration is 1.2mol / L;

[0035] (3) The hole transport layer Spiro-MeOTAD is spin-coated on the perovskite layer by the solution spin coating method,...

Embodiment 2

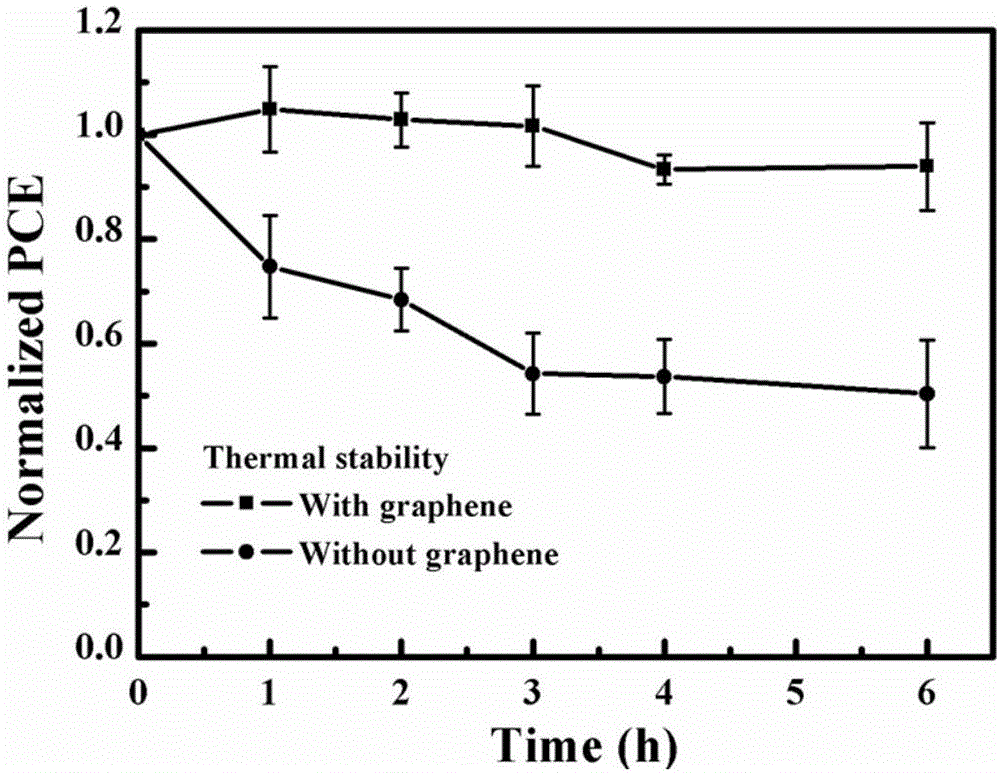

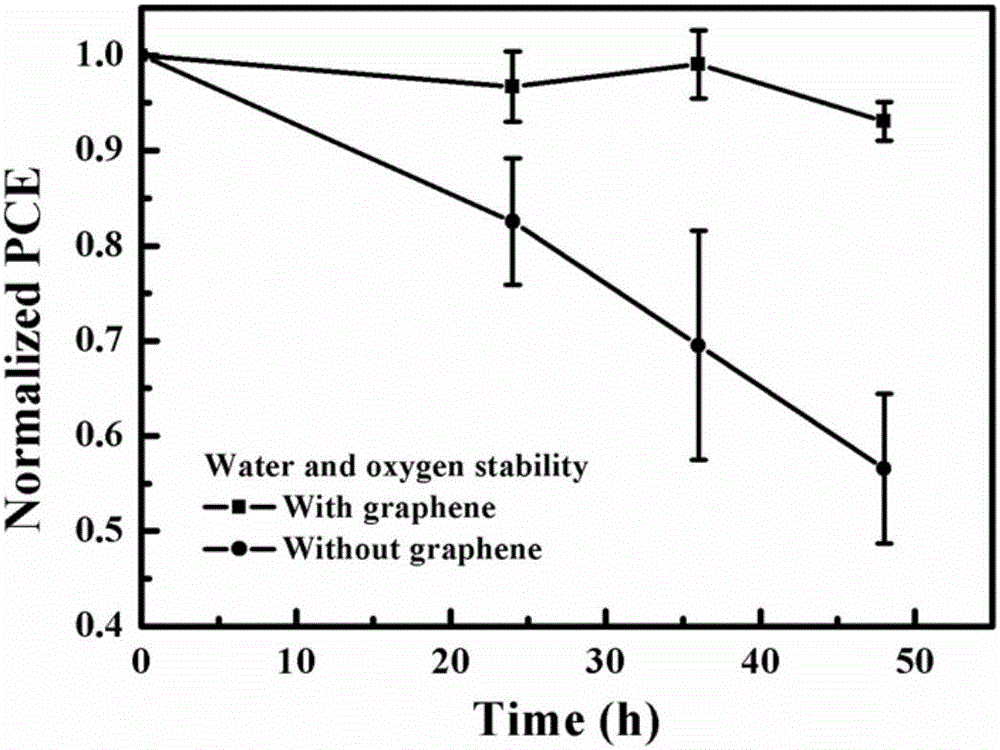

[0046] In this example, the thickness of the gold electrode is 90nm, the thickness of PDMS is 0.5mm, the material of the electron transport layer is ZnO, and the material of the hole transport layer is P3HT; wherein, the perovskite battery substrate and the graphene film are heated at 70°C at the same time Heating on the stage for 10 minutes, and then pasting the heated graphene film on the heated perovskite battery substrate, and then fumigated with solvent. Other steps are the same as Example 1. In this example, the efficiency of the perovskite cell with the graphene barrier was 14.6%. The thermal stability of the battery can reach 85% after being heated at 80°C for 6 hours continuously, and the water-oxygen stability can reach 90% after being placed in the air for 48 hours.

Embodiment 3

[0048] In this example, the thickness of the gold electrode is 100nm, the thickness of PDMS is 0.5mm, and the material of the electron transport layer is Nb 2 o 5 , the material of the hole transport layer is P3HT; among them, the multi-layer copper-based graphene film is etched in ferric chloride solution for 5-6 hours, then dried and heated at 80°C with the normal temperature perovskite battery substrate For lamination, place it on a hot stage at 85°C again and anneal it with toluene solvent for 15 minutes. Other steps are the same as Example 1. In this example, the efficiency of the perovskite cell with the graphene barrier was 15.12%. The thermal stability of the battery can reach 90% after being heated at 80°C for 6 hours continuously, and the water-oxygen stability can reach 95% after being placed in the air for 48 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com