Biogas purification device based on biological desulfurization technology and purification method thereof

A desulfurization device and biological desulfurization technology, applied in the field of biogas purification devices based on biological desulfurization technology, can solve the problems of poor biogas desulfurization effect, lack of feeding elements, blockage of packing racks, etc. Avoid unwieldy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

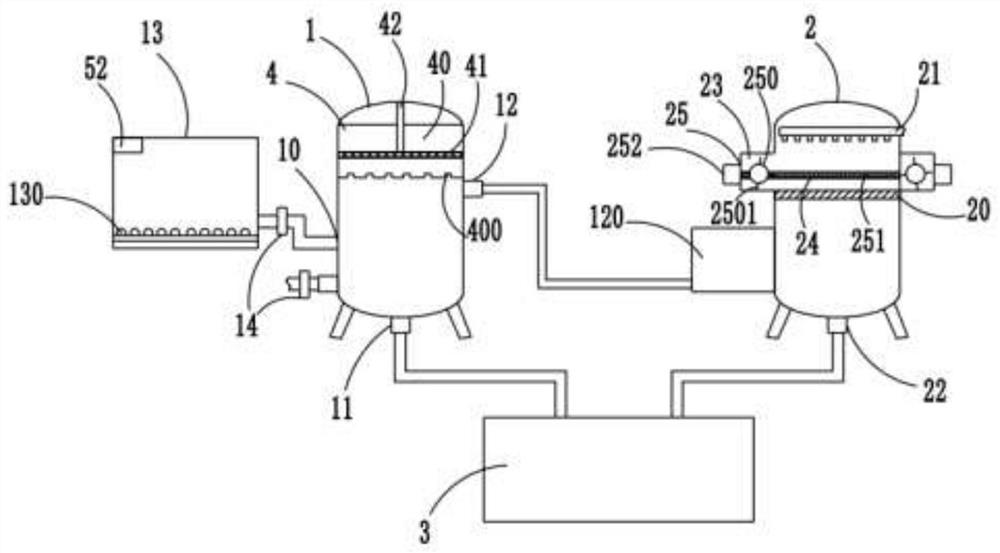

[0037] Embodiment 1: as figure 1 The shown biogas purification device based on biological desulfurization technology mainly includes a first-stage desulfurization device 1 with a biogas inlet 10 and a liquid discharge port 11 at the bottom and a biogas outlet 12 at the top, and a biogas outlet at the bottom. 12 connected and internally provided with a horizontal packing frame 20 and a spray device 21 from bottom to top, and a secondary desulfurization device 2 with a drain port 222 at the bottom, and a discharge port 11 and a drain port 22. Sulfur reactor 3 for sulfur removal treatment of the mixed liquid, mixing and pumping element 4, intelligent element 5, power supply for each electrical component;

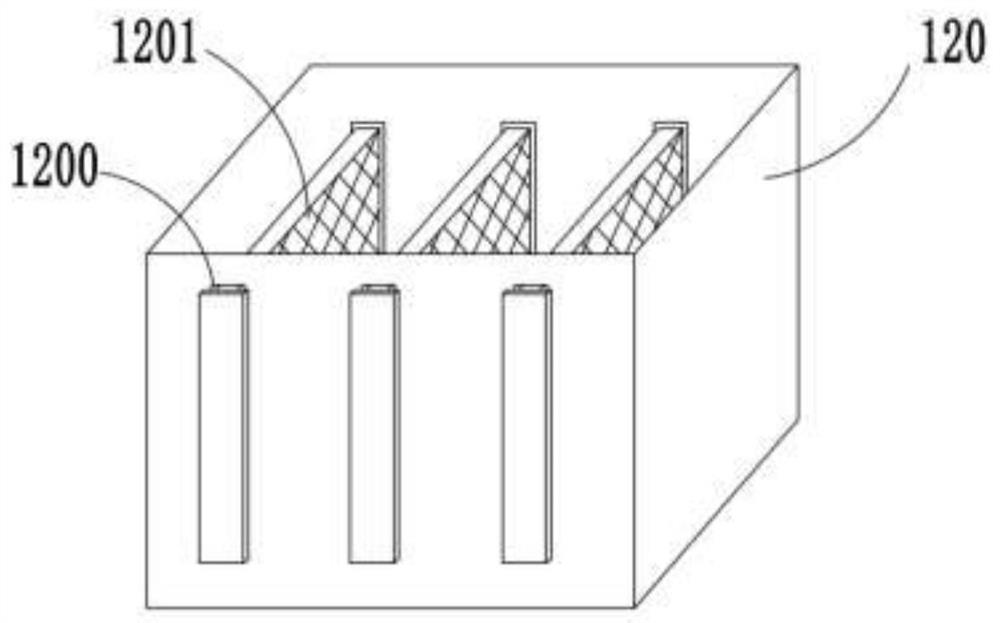

[0038] Such as figure 2 As shown, the primary desulfurization device 1 is connected to a liquid treatment tank 13 through a connecting pipe, and an aeration element 130 is provided inside the liquid processing tank 13. A one-way valve 14, a gas buffer dispersion box 120 is p...

Embodiment 2

[0048] Embodiment 2: as figure 1 The shown biogas purification device based on biological desulfurization technology mainly includes a first-stage desulfurization device 1 with a biogas inlet 10 and a liquid discharge port 11 at the bottom and a biogas outlet 12 at the top, and a biogas outlet at the bottom. 12 connected and internally provided with a horizontal packing frame 20 and a spray device 21 from bottom to top, and a secondary desulfurization device 2 with a drain port 222 at the bottom, and a discharge port 11 and a drain port 22. Sulfur reactor 3 for sulfur removal treatment of the mixed liquid, mixing and pumping element 4, intelligent element 5, power supply for each electrical component;

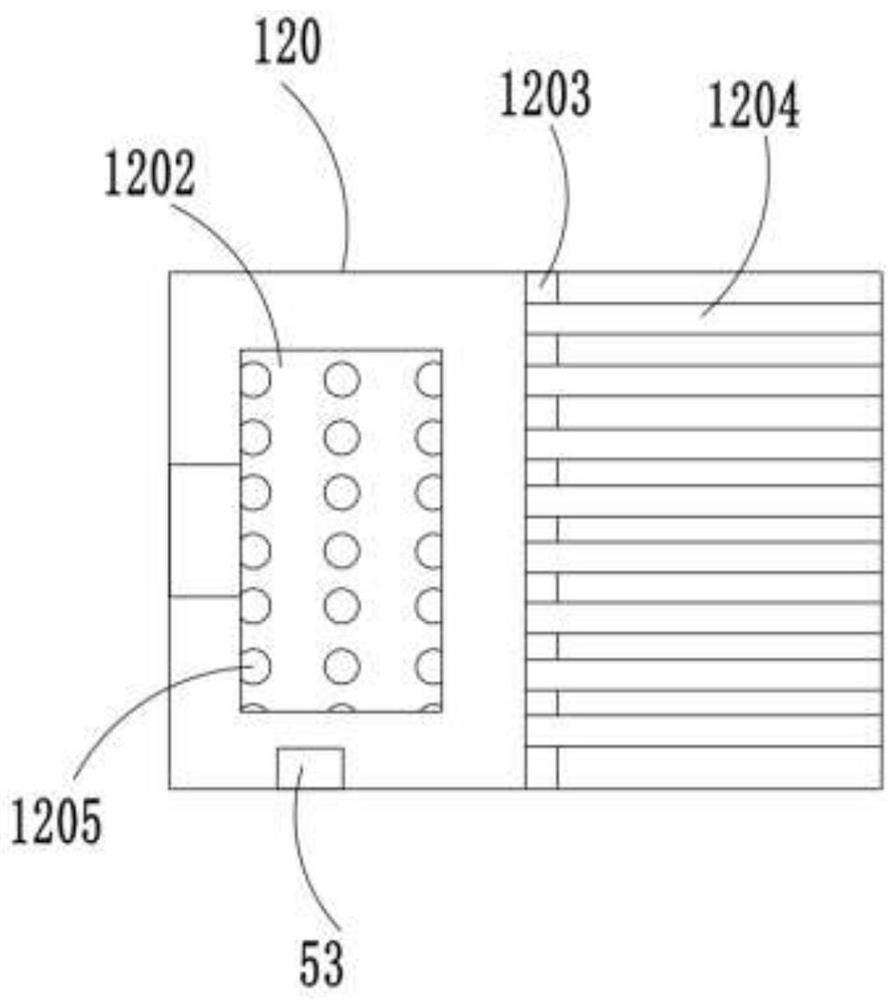

[0049] Such as image 3 As shown, the primary desulfurization device 1 is connected to a liquid treatment tank 13 through a connecting pipe, and an aeration element 130 is provided inside the liquid processing tank 13. A one-way valve 14, a gas buffer dispersion box 120 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com