Anisotropic nanocrystalline rare earth permanent magnet and preparation method therefor

A rare earth permanent magnet, anisotropic technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of the small number of rare earth permanent magnet slip systems, poor magnetic powder contact surface conditions, difficult plastic deformation, etc. problems, to achieve the effect of overcoming fewer slip systems, abundant types, and shortened temperature and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

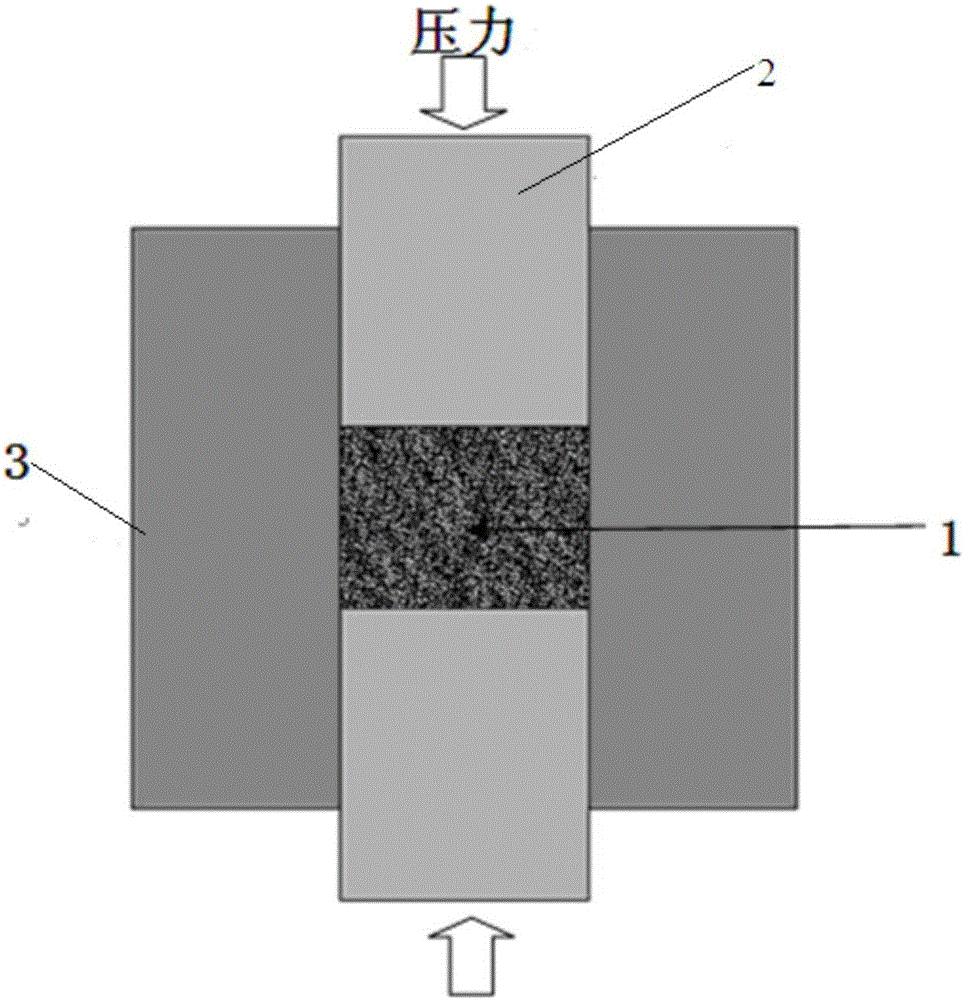

Method used

Image

Examples

Embodiment 1

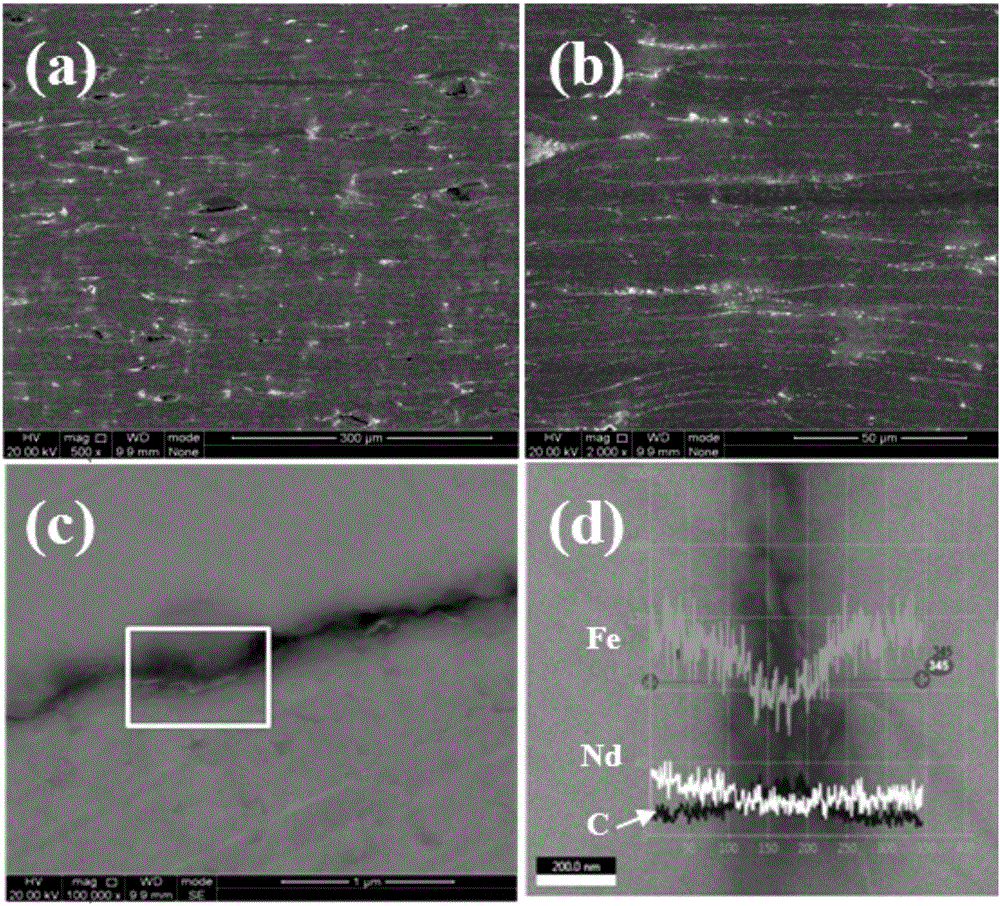

[0035] (1) According to the chemical formula Nd 29.89 Fe 66.15 co 5.93 Ga 0.64 B 0.92 Ingredients, the raw materials used are rare earth neodymium with a purity greater than 99.5%, gallium with a purity of 99.99%, cobalt with a purity of 99.9%, pure iron with a purity greater than 99.9%, and ferroboron with a boron content of 19.3% by weight;

[0036] (2) The configured Nd 29.89 Fe 66.15 co 5.93 Ga 0.64 B 0.92 The alloy raw materials are put into the smelting quick-setting crucible of the intermediate frequency induction furnace, and the vacuum degree reaches 10 -2 When Pa is above, power on and preheat until the vacuum degree reaches 10 again. -2 When the pressure of Ar in the furnace reaches -0.05MPa, adjust the power of the melting furnace to the melting power for smelting. After all the raw materials are melted, stir and refine for 3 minutes. After refining, the alloy liquid Pouring into a water-cooled copper mold to obtain Nd 29.89 Fe 66.15 co 5.93 Ga 0.64 B...

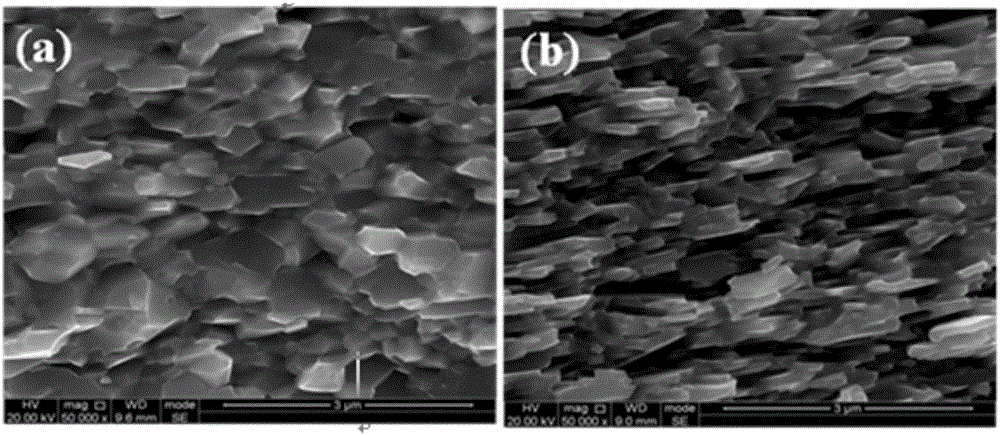

Embodiment 2

[0045] (1) According to the chemical formula MM 29.6 Fe 63.2 co 6.0 Ga 0.6 al 0.2 B 1.0 (MM is a mixed rare earth, mainly containing Ce, Nd, Pr, and a small amount of Dy) ingredients, the raw material MM used is 49.8wt% Ce, 25wt% Nd, 25wt% Pr, 0.2wt% Dy, and the purity is 99.99% gallium, cobalt with a purity of 99.9%, aluminum with a purity of 99.95%, pure iron with a purity greater than 99.9%, and ferroboron with a boron content of 19.3% by weight;

[0046] (2) The configured MM 29.6 Fe 63.2 co 6.0 Ga 0.6 al 0.2 B 1.0 The alloy raw materials are put into the smelting quick-setting crucible of the intermediate frequency induction furnace, and the vacuum degree reaches 10 -2 When Pa is above, power on and preheat until the vacuum degree reaches 10 again. -2 When the pressure of Ar in the furnace reaches -0.05MPa, adjust the power of the melting furnace to the melting power for smelting. After all the raw materials are melted, stir and refine for 3 minutes. After ref...

Embodiment 3

[0055] (1) According to the chemical formula Ce 33 Fe 66.15 Ga 0.5 B 1.35 Ingredients, the raw materials used are rare earth cerium with a purity greater than 99.5%, gallium with a purity greater than 99.9%, pure iron with a purity greater than 99.9%, and ferroboron with a boron content of 19.3 wt%.

[0056] (2) The configured Ce 33 Fe 66.15 Ga 0.5 B 1.35 The alloy raw materials are put into the smelting quick-setting crucible of the intermediate frequency induction furnace, and the vacuum degree reaches 10 -2 When Pa is above, power on and preheat until the vacuum degree reaches 10 again. -2When the pressure of Ar in the furnace reaches -0.05MPa, adjust the power of the melting furnace to the melting power for smelting. After all the raw materials are melted, stir and refine for 3 minutes. After refining, the alloy liquid poured into a water-cooled copper mold to obtain Ce 33 Fe 66.15 Ga 0.5 B 1.35 alloy ingot;

[0057] (3) Coarsely crush the alloy ingot into par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com