Measurement method of corrosiveness of electronic and electrical appliance service environment

A service environment, electronic and electrical technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of failure to measure the service environment of electronic and electrical appliances, insufficient accuracy, weak corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

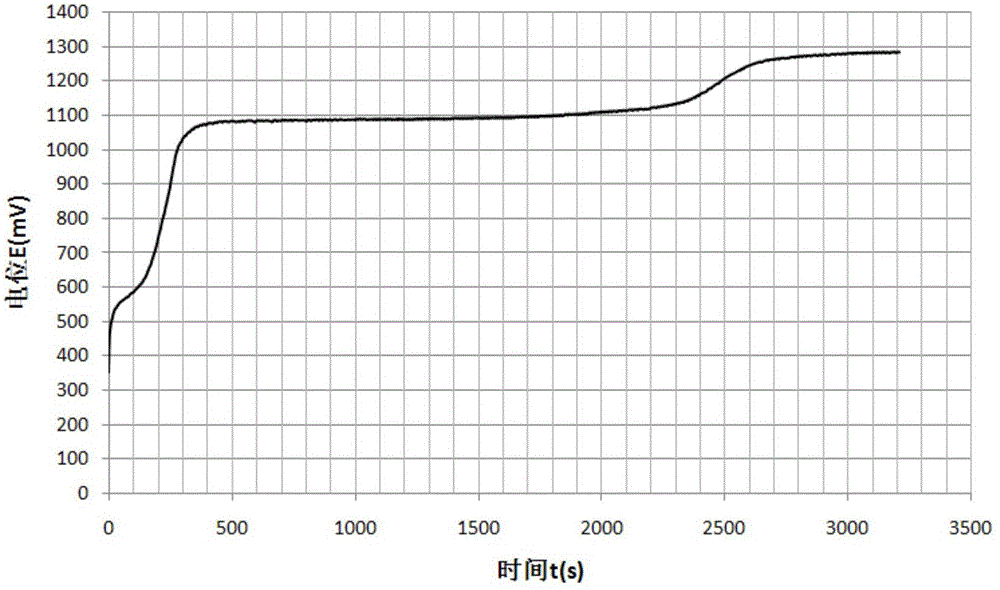

Image

Examples

Embodiment Construction

[0038] The measuring method of the corrosivity of the service environment of electronic appliances of the present invention comprises:

[0039] Step S1, preparing a copper test piece, the copper test piece has a purity of more than 99.99% and a surface area of 15 cm 2 to 30cm 2 The oxygen-free copper with high conductivity in between, the copper test piece is preferably in the shape of a copper sheet with a size of 90mm*12mm*0.5mm, and the copper test piece is surface treated according to the following steps in turn, so that the surface of the copper test piece should be free of Visible pits, no corrosion products, no oil stains and pollutants such as dust:

[0040] Step S1a, using No. 240 metallographic sandpaper plus lubricating wax to grind the copper test piece;

[0041] Step S1b, using No. 400 metallographic sandpaper plus lubricating wax to grind the copper test piece;

[0042] Step S1c, using No. 600 metallographic sandpaper plus lubricating wax to grind the copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com