Automatic chemical feeding and mixing method and device for detecting nitrite nitrogen content

A nitrite nitrogen, automatic dosing technology, applied in the direction of measuring devices, test sample preparation, color/spectral characteristics measurement, etc., can solve the problems of longer detection period, lower food intake, loss of oxygen, etc., to achieve The effect of increasing the number of effective collisions, saving time and energy consumption, and avoiding cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

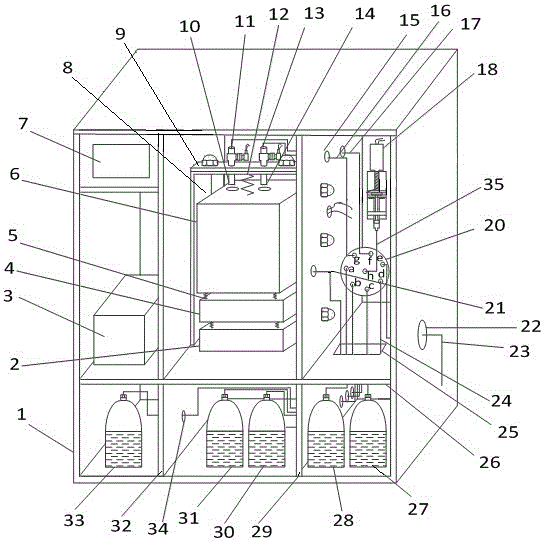

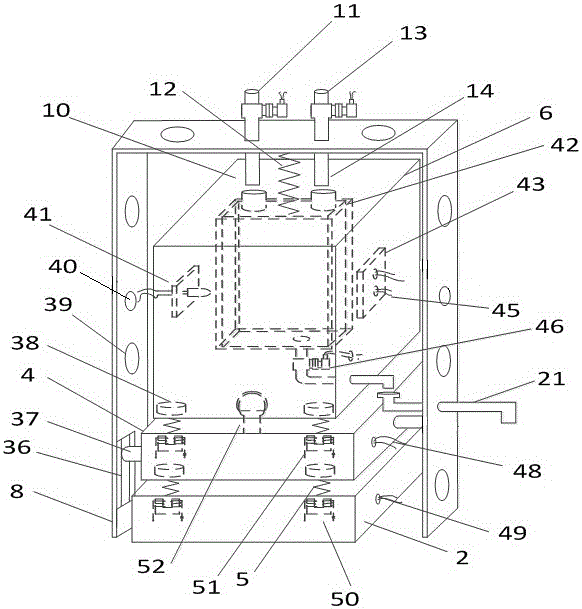

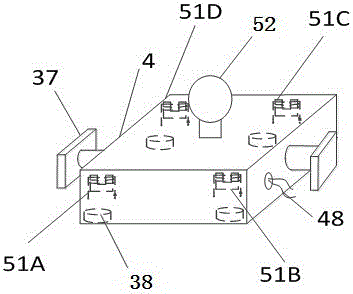

[0025] see figure 1The outermost part of the automatic dosing and mixing device for detecting nitrite nitrogen in the present invention is a box body 1, and the box body 1 is square. Divide into six small compartments, three at the top and three at the top and bottom. Wherein, the horizontal partition 26 divides the interior of the box body 1 into upper and lower layers, and the left longitudinal partition 32 and the right longitudinal partition 29 are perpendicular to the horizontal partition 26, and the upper and lower floors are respectively divided into three small compartments, each small compartment Different modules are placed in the room. In the three small compartments on the lower floor, waste liquid bottle 33, distilled water bottle 31, cleaning solution bottle 30, N-(1-naphthyl)-ethylenediamine dihydrochloride solution bottle 28, 4- Sulfonamide and hydrochloric acid solution bottle 27; These five bottle tops are all connected with pipeline, and pipeline mouth is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com