An adaptive once-through boiler drainage expansion control device and drainage system

A technology for drain expansion and once-through boilers, applied in control systems, boiler cleaning devices, steam traps, etc., can solve problems such as water temperature mismatch in condenser hot wells, increased water consumption and heat energy consumption in power plants, and difficulty in parameter adjustment. Achieve the effects of improving energy utilization efficiency and system safety, reducing steam emission losses, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

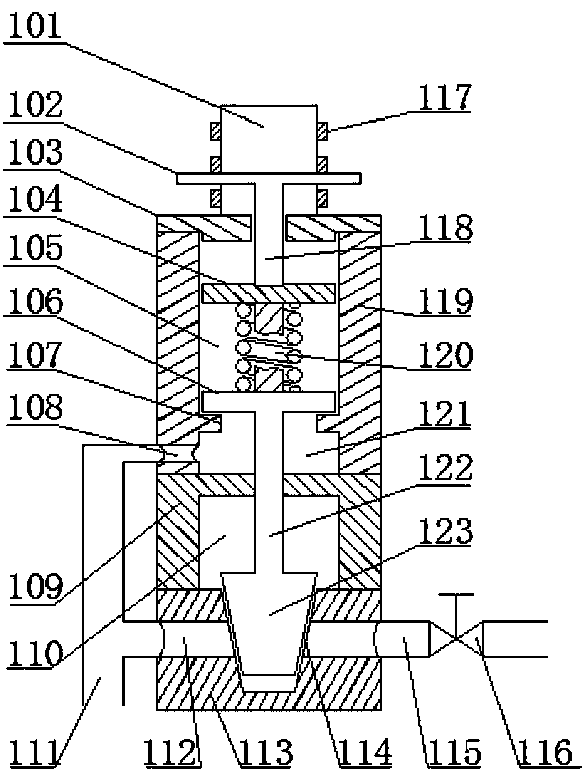

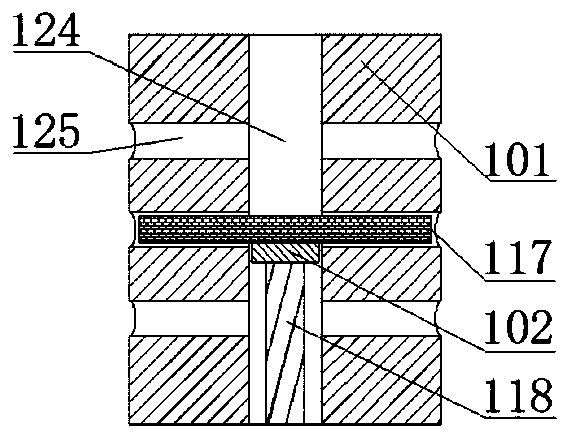

[0031] see Figure 1 to Figure 3 , the hydrophobic expansion control device 4 in this embodiment is arranged axisymmetrically along the height increasing direction (coordinate axis Z direction), and sequentially includes a valve body base 113, a valve stem base 109, a slider base 119 and a positioning base 101 , their central axis and seat sealing surface 114, sealing valve core 123, sealing valve stem 122, main slider 106, auxiliary slider 104, pressure regulating connecting rod 118, base sealing cover 103, pressure regulating top plate 102, positioning The central axes of the bases 101 coincide with each other. Wherein the stem base 109 and the slider base 119 are axisymmetric hollow structures.

[0032] The valve body base 113 has a circular hole-shaped steam flow channel 112 running through it in the horizontal direction, and a circular platform hollow valve seat sealing surface 114 is provided in the axial direction, completely penetrating to the upper end surface of the...

Embodiment 2

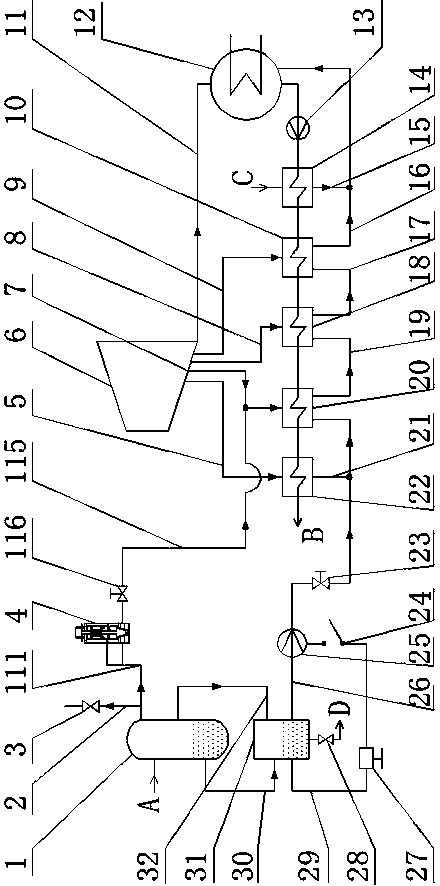

[0045] Still take the once-through boiler and the drainage system in Embodiment 1 as an example. In the early stage of boiler start-up, the expansion steam pressure in the hydrophobic expansion vessel is 0.1 MPa and the temperature is 100°C, and the main slider 106 in the hydrophobic expansion control device 4 cannot be pushed upward, and the steam flow channel 112 is blocked by the sealing valve core 123 . At this time, the water quality of the boiler body drain A cannot meet the condensate water quality requirements in the condenser 12, the drain pump 25 stops running, the blowdown valve 28 is opened, the boiler body drain A enters the drain tank 31 through the drain artesian pipe 30, and passes through the sewage pipe Drain to accident sink.

[0046] When the water quality of the boiler body drainage A reaches the condensed water quality requirement in the condenser 12, close the drain valve 28, and after the water level in the drainage tank 31 gradually rises beyond the ma...

Embodiment 3

[0048] Taking the drainage system in Example 1 as an example, under the rated working conditions of the once-through boiler, the evaporation capacity is 3030t / h, the superheated steam pressure is 26.3MPa, and the superheated steam temperature is 605°C.

[0049]The steam parameters of the steam extraction pipe 5 in the fifth section of the steam turbine are 0.636MPa and 338°C respectively, the steam parameters of the steam extraction pipe 7 in the sixth section are 0.329MPa and 262°C respectively, and the drain temperature in the drain pipe 21 of the #5 low-pressure heater is 142°C, by adjusting the position of the positioning slider 117 of the drain expansion control device 4, the drain A of the boiler body enters the drain expander 1 to depressurize and cool down to become expansion steam and drain at a pressure of 0.39MPa and a temperature of 143°C. The water that enters the water pump 25 from the water tank 31 through the water outlet pipe 26 is boosted from 0.39 MPa to 0.65...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com