Fastening and connecting assembly and structure, disassembling method, track structure, crankshaft connecting rod system, bone connecting device and bone connecting method

A technology for fastening connections and components, applied in the direction of connecting components, locking fasteners, threaded fasteners, etc., which can solve the problem of the difficulty of the anti-rotation sleeve, the useless fastening of the connection components, and the inability to stop the rotation from the first Problems such as taking out of the hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

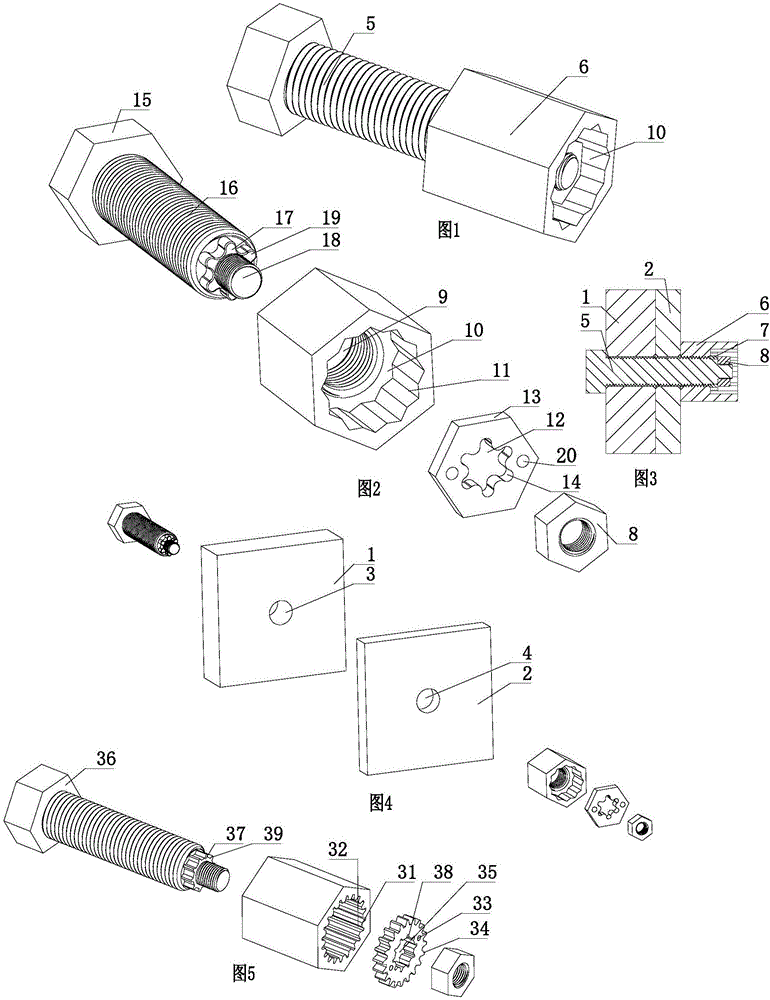

[0150] As shown in FIGS. 1 to 4 , a fastening connection structure includes a fastening connection assembly, a mother body 1 and an appendage 2 . The base body 1 is provided with a through hole 3 , and the attached body 2 is provided with a through hole 4 .

[0151] The fastening connection assembly includes a screw rod 5, a lock nut 6, an anti-rotation sleeve 7, and an anti-rotation sleeve limiter. The stopper of the anti-rotation sleeve is a blocking nut 8.

[0152] The locking nut 6 is provided with a threaded through hole 9 and a first anti-rotation hole 10 communicating with the threaded through hole 9 , and the minimum diameter of the first anti-rotation hole 10 is larger than the diameter of the threaded through hole 9 . First anti-rotation portions 11 arranged in the circumferential direction are arranged on the hole wall of the first anti-rotation hole 10 . The hole wall of the first anti-rotation hole 10 is an intersecting structure in which two regular hexagonal h...

Embodiment 2

[0160] As shown in Figure 5, different from Embodiment 1, the hole wall of the first anti-rotation hole 31 is in the shape of an internal gear, and the hole wall of the first anti-rotation hole 31 is evenly arranged with a plurality of axial trapezoidal grooves in the circumferential direction. A single trapezoidal groove forms a first anti-rotation portion 32 . The outer circumference of the anti-rotation sleeve 33 is in the shape of an external gear matching the hole wall of the first anti-rotation hole 31 , and the outer circumference of the anti-rotation sleeve 33 is evenly arranged with a plurality of axial trapezoidal teeth, and a single trapezoidal tooth forms the second anti-rotation part 34 . The anti-rotation through hole 35 of the anti-rotation sleeve 33 is an internal gear shape, and the anti-rotation shaft 37 of the screw rod 36 is an external gear shape matched with the anti-rotation through hole 35 of the internal gear shape. A plurality of axial trapezoidal gr...

Embodiment 3

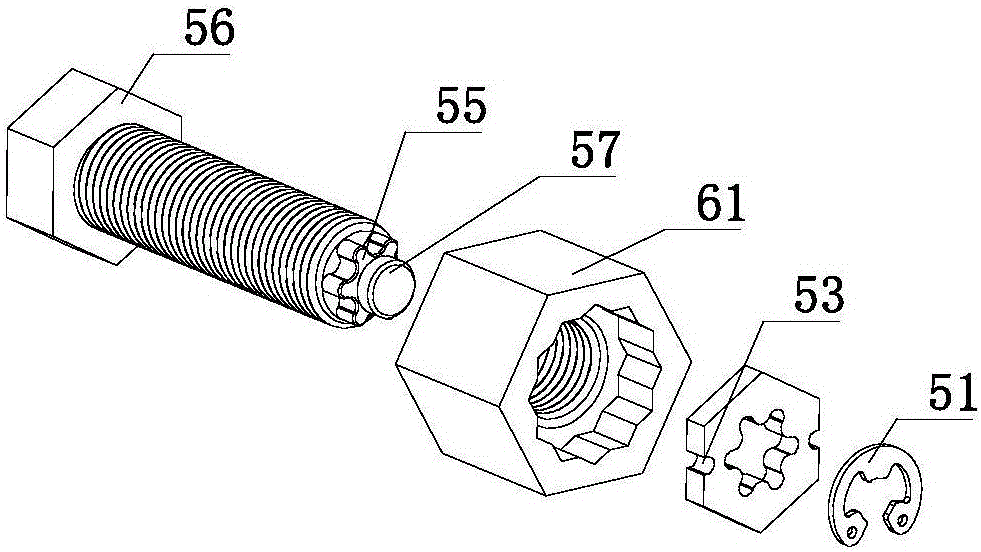

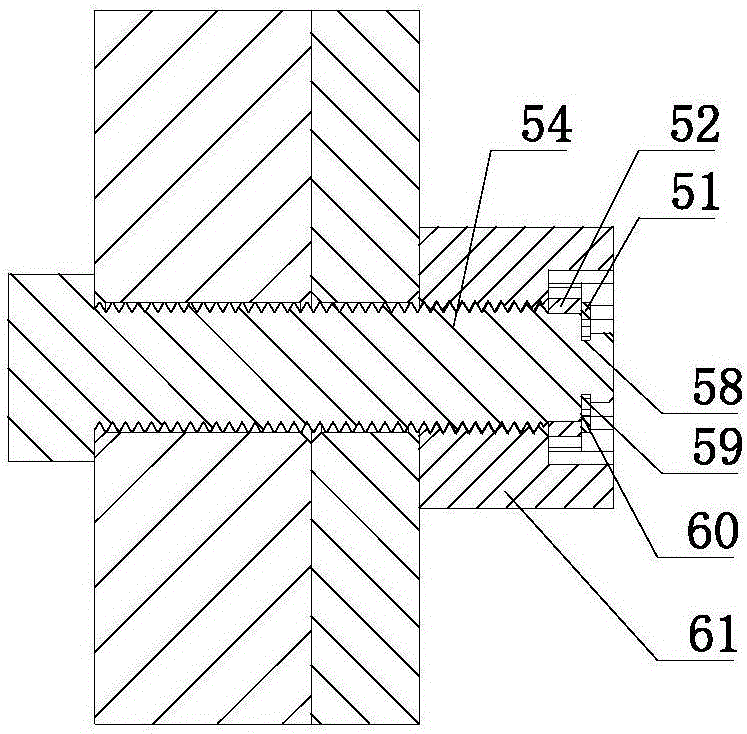

[0163] Such as Figure 6 , Figure 7 As shown, the difference from Embodiment 1 is that the stopper of the anti-rotation sleeve is a snap ring 51 . Two axial clamping recesses 53 symmetrical to the axis of the anti-rotation sleeve 52 are provided on the outer periphery of the anti-rotation sleeve 52 . A mounting portion 57 is provided on the end surface of the anti-rotation shaft 55 of the screw 54 away from the resisting portion 56 , and an annular locking groove 58 is provided on the outer periphery of the mounting portion 57 , and the locking groove 58 faces the side wall 59 of the anti-rotation shaft 55 and the anti-rotation shaft 55 The end face 60 is flush, so that when the snap ring 51 axially limits the stop sleeve 52, there is no axial gap between the stop sleeve 52, the lock nut 61, and the snap ring 51, and the stop sleeve 52 does not fit in the slot 58. It can move axially, which greatly reduces noise in places with large vibrations. The maximum outer diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com