copper zinc alloy

An alloy, copper-zinc technology, applied in the field of metal materials, can solve the problems that the hardness and toughness of copper-zinc alloys cannot meet the actual needs, and achieve the effects of high toughness, high surface quality, and increased hardness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

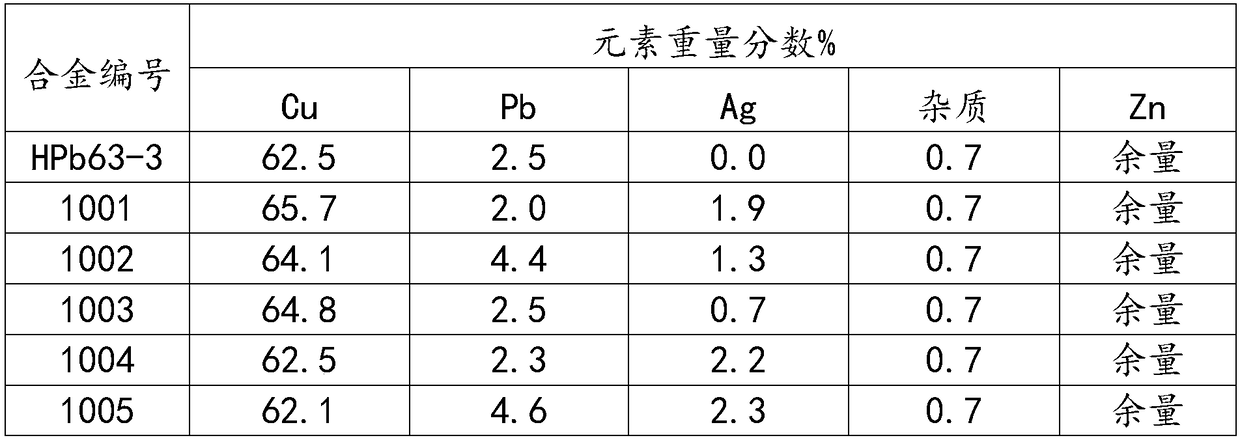

[0033] Table 1 Composition of copper-zinc alloy

[0034]

[0035]

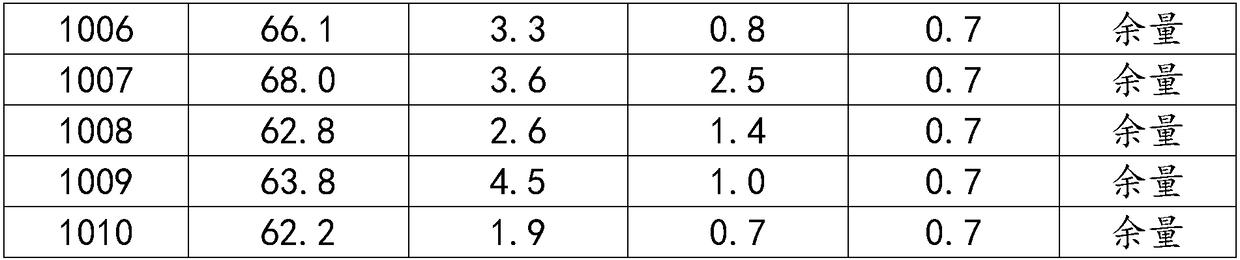

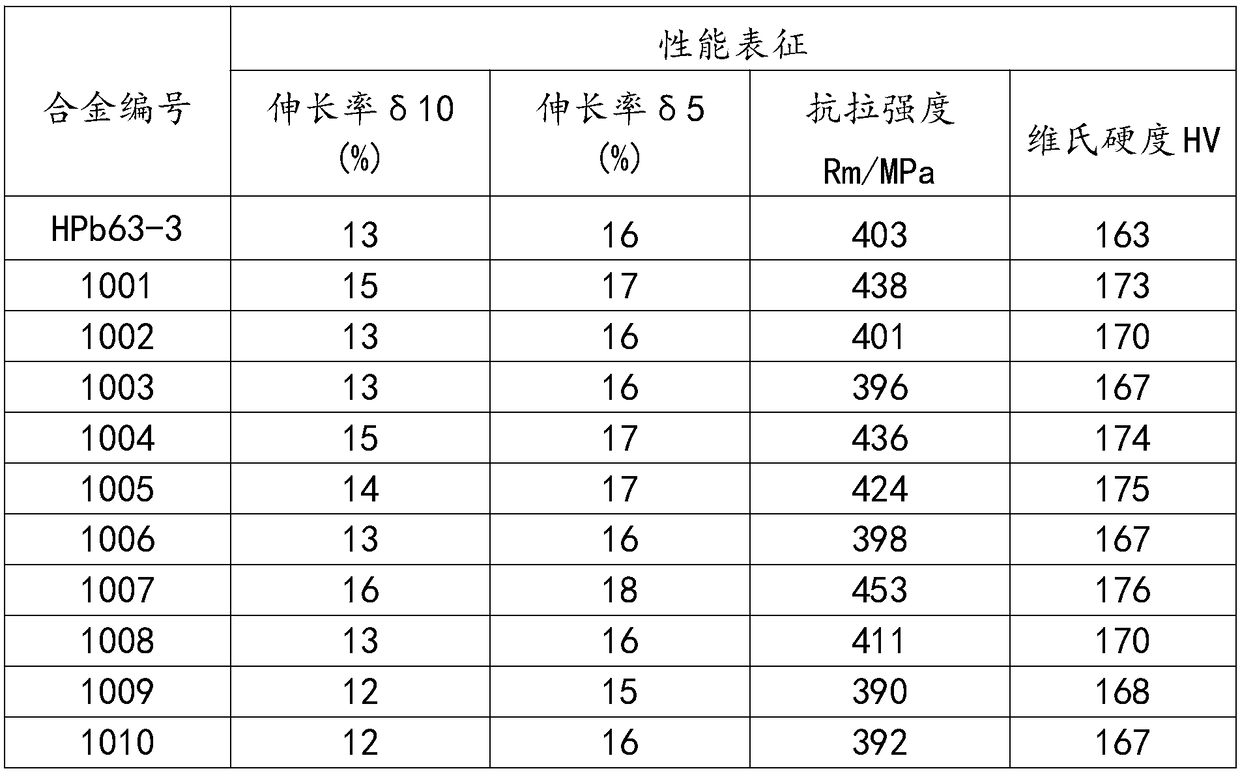

[0036] Table 2 Performance Characterization of Copper-Zinc Alloy

[0037]

[0038] The elongation δ10, elongation δ5, and tensile strength of the above alloy materials are obtained by testing according to the method recorded in GBT228-2002.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com