High-temperature corrosion inhibitor for oilfield exploitation and petroleum refining process and preparation method of high-temperature corrosion inhibitor

A high-temperature corrosion inhibitor, petroleum refining technology, applied in the petroleum industry, chemical instruments and methods, earth-moving drilling, etc., can solve the problems of affecting the production and operating environment, irritating odor, limited corrosion inhibition effect, etc. To achieve the effect of safe and reliable production and use operation process, good corrosion inhibition effect and good corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

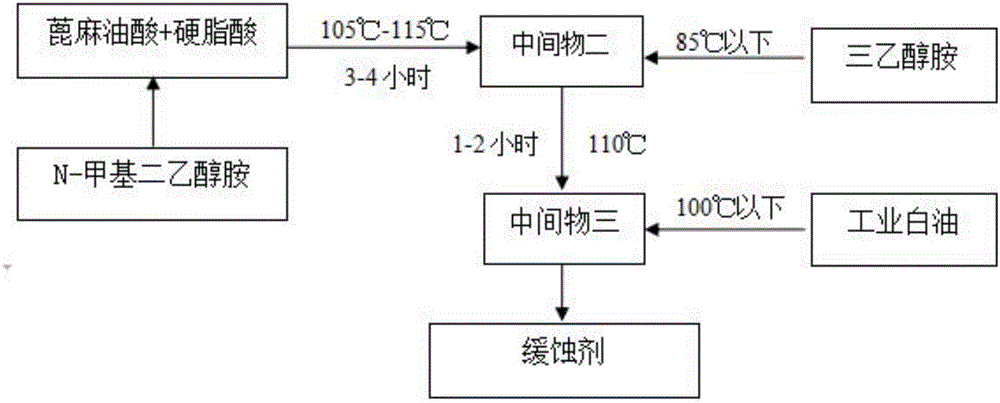

[0017] Such as figure 1 As shown, this example provides a high-temperature corrosion inhibitor used in oil field exploitation and petroleum refining processes. The specific preparation method is as follows: Weigh 6 kg of ricinoleic acid and 2 kg of stearic acid and mix them uniformly to obtain intermediate one. Add 1.44kg of N-methyldiethanol to the intermediate one, raise the temperature to 105°C, keep stirring at 105-115°C for 3h to obtain intermediate two. The intermediate product 2 was cooled down to 85° C., and then 480 g of triethanolamine was added to the intermediate product 2, and stirred and kept at 105° C. for 1 hour to obtain the intermediate product 3 . The intermediate product 3 was cooled down to 100°C, and then 2.8kg of industrial white oil was added, kept stirring continuously and dropped to room temperature to obtain the high temperature corrosion inhibitor of this example.

Embodiment 2

[0019] This example provides a high-temperature corrosion inhibitor used in oil field exploitation and petroleum refining processes. The specific preparation method is as follows: Weigh 7 kg of ricinoleic acid and 3 kg of stearic acid and mix them uniformly to obtain intermediate one. 1.9 kg of N-methyldiethanol was added to the intermediate one, the temperature was raised to 110°C, and kept at 105-115°C with stirring and heat preservation for 3.5h to obtain intermediate two. The intermediate product 2 was cooled down to 80° C., and then 700 g of triethanolamine was added to the intermediate product 2, and stirred and kept at 110° C. for 1.5 h to obtain the intermediate product 3 . The intermediate product 3 was cooled down to 95°C, then 3.8 kg of industrial white oil was added, and the high temperature corrosion inhibitor of this example was obtained by keeping stirring continuously and dropping to room temperature.

Embodiment 3

[0021] This example provides a high-temperature corrosion inhibitor used in oil field exploitation and petroleum refining processes. The specific preparation method is as follows: Weigh 8 kg of ricinoleic acid and 4 kg of stearic acid and mix them uniformly to obtain intermediate one. 2.4 kg of N-methyldiethanol was added to the intermediate one, the temperature was raised to 115° C., and kept at 105-115° C. for 3 h with stirring to obtain intermediate two. The intermediate product 2 was cooled to 80° C., and then 960 g of triethanolamine was added to the intermediate product 2, and stirred and kept at 115° C. for 2 hours to obtain the intermediate product 3 . The intermediate product 3 was cooled down to 90°C, and then 4.8 kg of industrial white oil was added, and the high-temperature corrosion inhibitor of this example was obtained by keeping stirring continuously and dropping to room temperature.

[0022] The corrosion inhibition rate of the high-temperature corrosion inhib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com