Large-particle ammonium nitrate product and preparation method thereof

A technology of ammonium nitrate and large particles, which is applied in the direction of ammonium nitrate, chemical instruments and methods, and ammonia compounds. The effect of high looseness and low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be described in detail below.

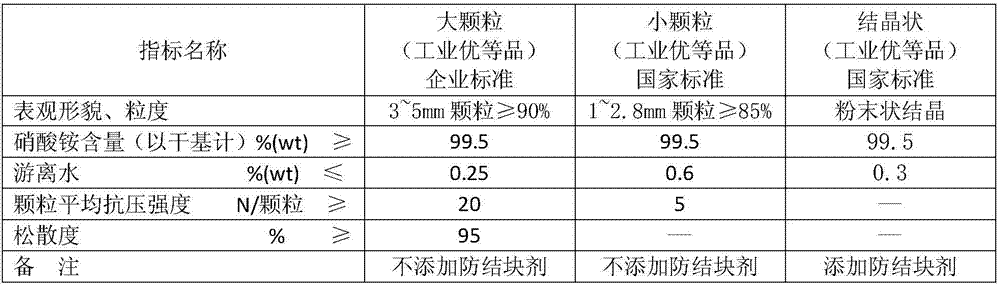

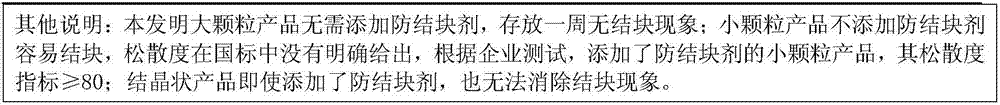

[0026] The granular ammonium nitrate created by the present invention has a particle size of more than 3mm, preferably 3-5mm. Further, the ammonium nitrate has an average compressive strength of more than 20N / particle; free water content is less than 0.25wt%; under the condition of not adding caking agent, the looseness is more than 95%. The product index of large particle ammonium nitrate provided by the present invention is compared with the existing product index as shown in Table 1.

[0027] Table 1

[0028]

[0029]

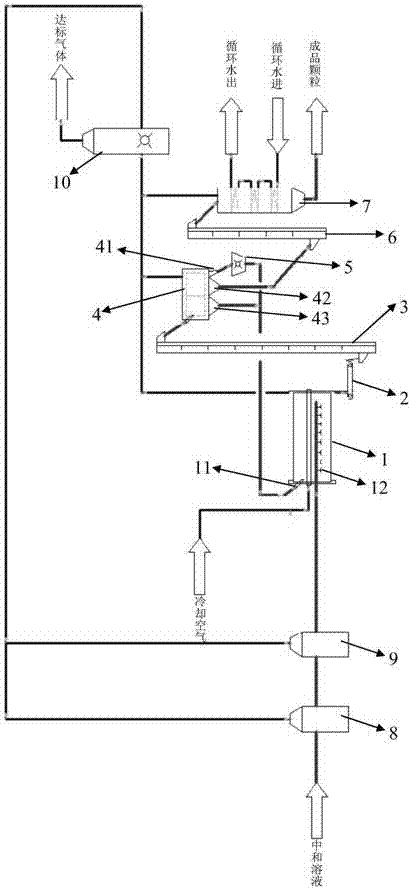

[0030] The present invention creates a method for preparing the above-mentioned large-grain ammonium nitrate, which includes the following granulation steps: the ammonium nitrate particles are repeatedly coated by the atomized ammonium nitrate concentrate, and the ammonium nitrate concentrate is coated with ammonium nitrate after each coating. The surface of the particles is allowed to crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com