Preparation method for super absorbent resin

A technology of super absorbent resin and resin particles, which is applied in the fields of daily hygiene materials, the manufacture of super absorbent resin, and the preparation of polyacrylic acid type super absorbent resin, can solve the problems of affecting application performance, low compressive water absorption, gel It can improve the drying efficiency, improve the anti-caking performance, and reduce the amount of glue linking agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

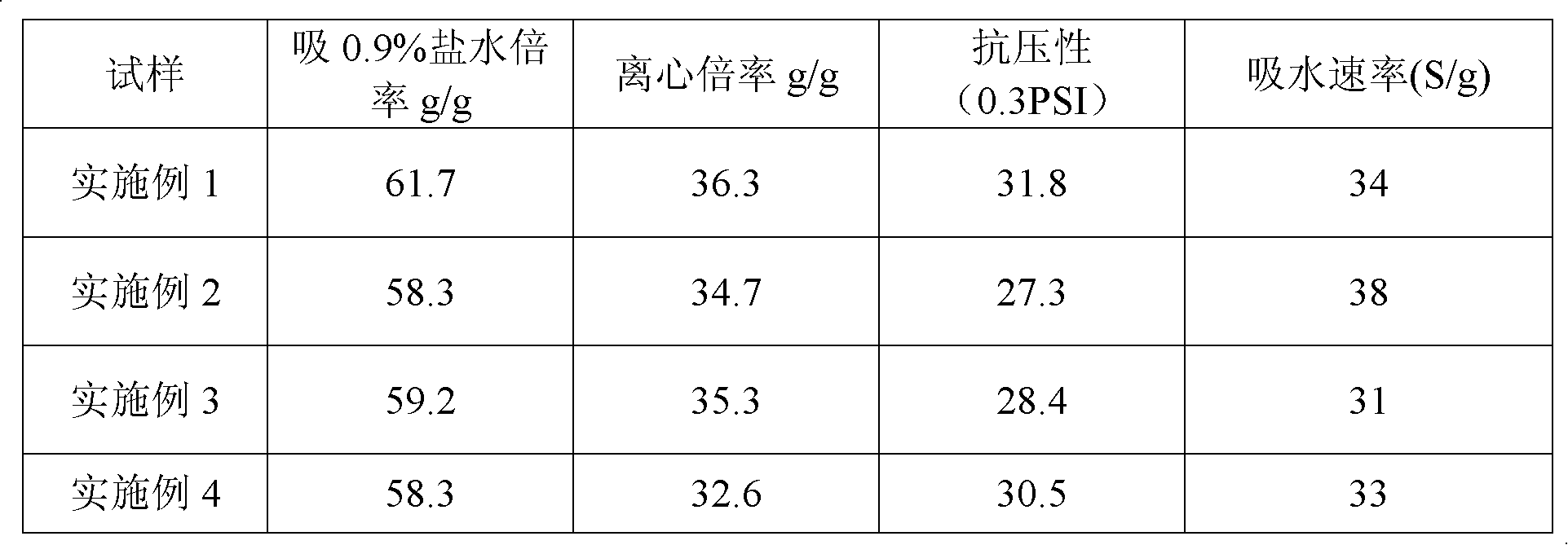

Embodiment 1

[0021] Add 200g of high-purity acrylic acid and 180g of deionized water into a 2000ml four-necked flask, which is equipped with a stirrer, a reflux condenser, a dropping funnel and a thermometer. Under the condition of temperature control at 40° C., 173.5 g of 48% wt % sodium hydroxide aqueous solution was added dropwise into the flask with a dropping funnel to carry out neutralization reaction. Continue to add cross-linking agent N,N'-methylenebisacrylamide (MBA): 0.04g, polyethylene glycol 2000: 0.24g. Pour the uniformly mixed solution into a 2000ml beaker, heat it in an electric furnace to 35°C, add 0.60g of sodium persulfate and 0.60g of sodium sulfite under stirring, and start the reaction after 3 minutes. After the reaction is completed, a hydrogel is obtained. The obtained colloid is granulated with a small meat grinder, dried in a blast oven, and finally pulverized. A total of 241.5 g of water-absorbent resin particles was obtained. The obtained resin particles were ...

Embodiment 2

[0023]Add 200g of high-purity acrylic acid and 200g of deionized water into a 2000ml four-neck flask equipped with a stirrer, a reflux condenser, a dropping funnel and a thermometer. Under the condition of external cooling and temperature control of 30° C., 173.5 g of 48% wt % sodium hydroxide aqueous solution was added dropwise into the flask with a dropping funnel to carry out neutralization reaction. Continue to add cross-linking agent MBA: 0.1 g, polyethylene glycol diglycidyl ether: 0.06 g. Pour the uniformly mixed solution into a 2000ml beaker, heat it in an electric furnace to 35°C, add 0.60g of sodium persulfate and 0.60g of sodium sulfite under stirring, and start the reaction after 3 minutes. After the reaction is completed, a hydrogel is obtained. The obtained colloid is granulated with a small meat grinder, dried in a blast oven, and finally pulverized. A total of 242.3 g of water-absorbent resin was obtained. The obtained resin particles were subjected to second...

Embodiment 3

[0025] Add 200g of high-purity acrylic acid and 250g of deionized water into a 2000ml four-necked flask, which is equipped with a stirrer, a reflux condenser, a dropping funnel and a thermometer. Under the condition of external cooling and temperature control of 40°C, 174.9g of sodium bicarbonate was added dropwise into the flask with a dropping funnel to carry out neutralization reaction. Continue to add cross-linking agent MBA: 0.03g, polyethylene glycol 2000: 0.24g. Pour the uniformly mixed solution into a 2000ml beaker, heat it in an electric furnace to 35°C, add 0.60g of sodium persulfate and 0.60g of sodium sulfite under stirring, and start the reaction after 3 minutes. After the reaction is completed, a hydrogel is obtained. The obtained colloid is granulated with a small meat grinder, dried in a blast oven, and finally pulverized. A total of 242.3 g of water-absorbent resin particles was obtained. The obtained resin particles were subjected to secondary crosslinking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com