Multi-directional vamp polishing device

A technology of shoe upper and end face, which is applied to the grinding drive device, the device for fixing the grinding wheel, and footwear, etc., can solve the problems of the weight of the grinding wheel, affecting the quality of leather shoe grinding, and the grinding machine not using centralized management operations, etc. The process is convenient and effective, and the structure principle is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

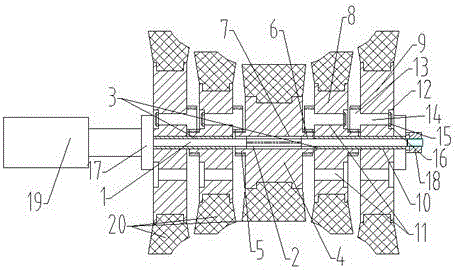

[0012] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0013] Such as figure 1 The shown multi-directional vamp grinding device includes a round rod 1 connected in series, a locking boss 2, an isolation sleeve 3, a driving wheel 4, an outer tooth boss 5, a round rod perforation 6, a slot 7, Middle runner 8, outer runner 9, sleeve perforation 10, adjustment jack 11, ring groove 12, adjustment outer tooth 13, insertion rod 14, positioning groove 15, snap spring 16, limit baffle 17, compression screw Cap 18, constant speed motor 19, ring brush 20.

[0014] The locking boss 2 is located in the middle section of the cylindrical surface of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com