Metal powder and preparation and application thereof

A metal powder, metal micropowder technology, applied in the field of materials, can solve the problem of not being able to cover the X-band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] The present invention also provides a method for preparing the metal powder, the method comprising the following steps:

[0109] 1) providing a mixture comprising Fe, M and R according to the atomic number ratio of the metal powder;

[0110] 2) melting the mixture described in step 1) under the protection of an inert gas to obtain an alloy comprising Fe, M and R;

[0111] 3) pulverizing the alloy obtained in step 2) to obtain metal fine powder comprising Fe, M and R;

[0112] 4) Optionally nitriding the metal fine powder obtained in step 3) to obtain the metal powder.

[0113] In another preferred example, M and R are as defined above.

[0114] In another preferred embodiment, the inert gas is selected from the group consisting of Ar, H 2 , He, Ne, Kr, or combinations thereof.

[0115] In another preferred example, the number of smelting is 1-10 times, preferably 2-5 times.

[0116] In another preferred embodiment, the crushing includes the following steps:

[011...

Embodiment 1

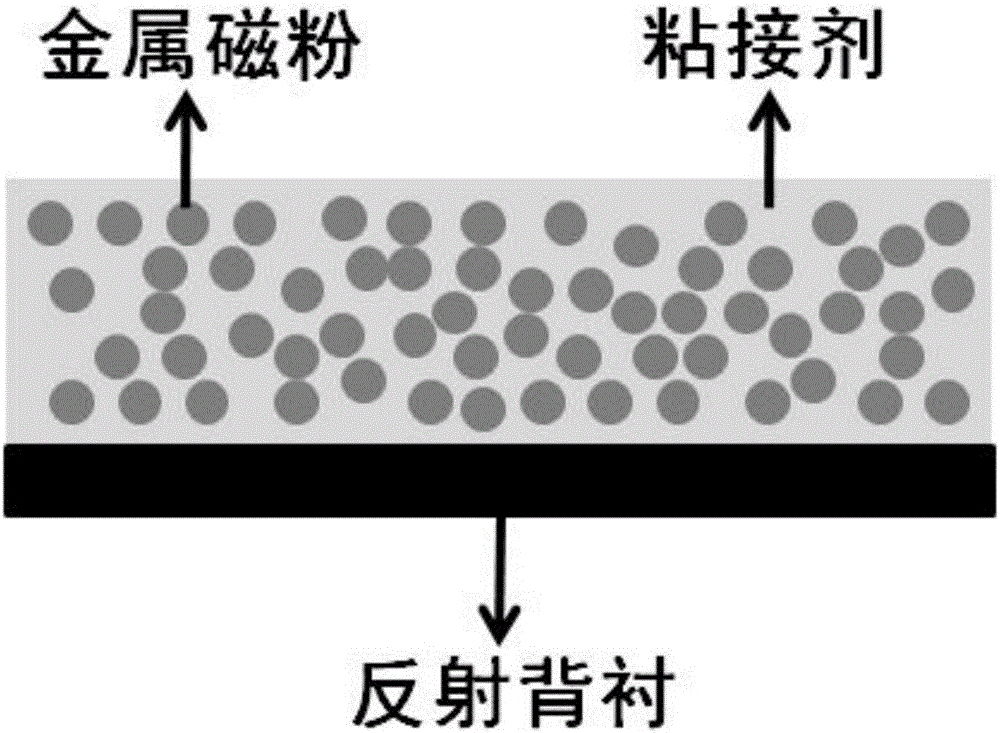

[0190] Example 1Fe 72 co 10 Ce 5 PR 5 N 8 Metal powder 1-1, styrene-butadiene rubber and copper foil composite absorbing material 1

[0191] Weigh Ce, Pr, Fe and Co elements according to the alloy ratio, melt them into a master alloy under the protection of an inert gas (such as Ar, He, Ne and / or Kr), and use a melt rapid quenching method to obtain a quenched alloy strip. The linear speed of melt quenching is 10 m / s;

[0192] After coarse crushing, the quick-quenched strip is ground into powder by ball milling. The ball mill is wet-milled by adding isopropanol and phthalate coupling agent. hour, obtain a metal powder 1 with a particle size of less than 4 microns;

[0193] Put the ball-milled metal powder 1 in a high-pressure reactor for nitriding, pressurize pure nitrogen to 5MPa, control the temperature at 350°C, and control the time for 2 hours to ensure the formation of a single soft magnetic nitriding phase to obtain metal powder 1-1, the particle size is about 3.5 ...

Embodiment 2

[0200] Example 2Fe 2 co 89 PR 3 Y 3 Nd 3 Wave-absorbing material composed of metal micropowder 2, TPU and graphene conductive film 2

[0201] Weigh Pr, Y, Nd, Fe and Co elements according to the alloy ratio, melt them into a master alloy under the protection of an inert gas (such as Ar, He, Ne and / or Kr), and use the melt rapid quenching method to obtain a quenched alloy strip material, the linear speed of melt quenching is 20 m / s;

[0202] After coarse crushing, the quick-quenched strip is ground into powder by ball milling. The ball mill is wet-milled by adding isopropanol and phthalate coupling agent. hours, the metal micropowder 2 with a particle size of less than 4 microns is obtained, and its particle size is about 3.5 microns;

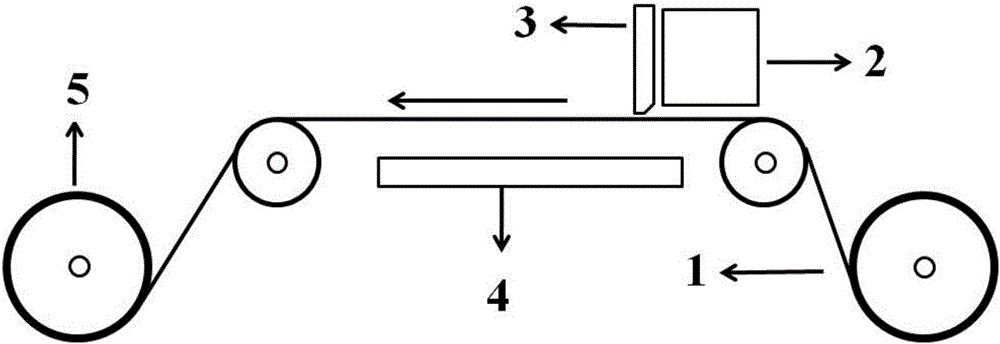

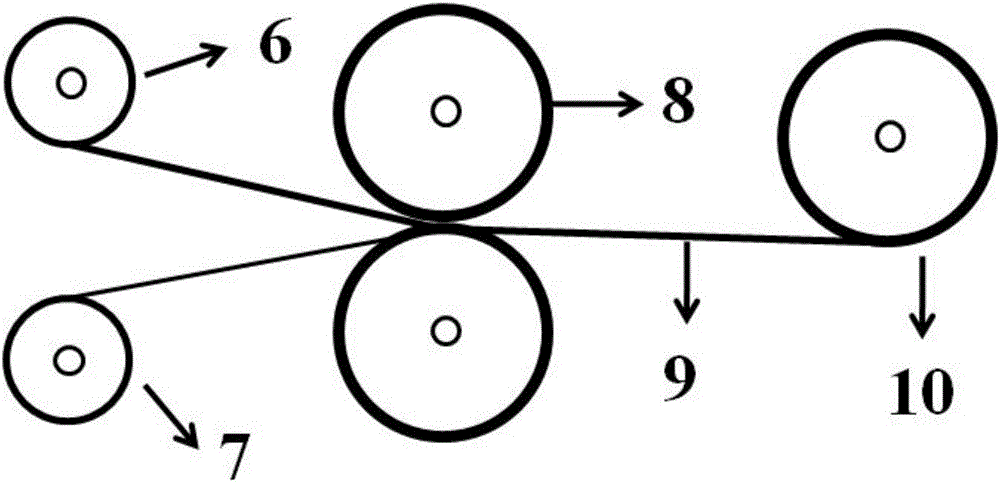

[0203] Mix TPU, acetone and toluene, and mix them into a wave-absorbing slurry according to the weight ratio of TPU and metal micropowder 2 at a ratio of 1:3.5. After the slurry is stirred evenly, it is poured into the casting feeding tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com