Accurate and continuous feeding device for punching of clutch coil housing

An uninterrupted and clutch technology, applied in the field of stamping equipment, can solve the problems of safety hidden danger that the automatic feeding device cannot achieve continuity, labor consumption, and low efficiency of stamping manual feeding, and achieves a simple structure, convenient operation, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

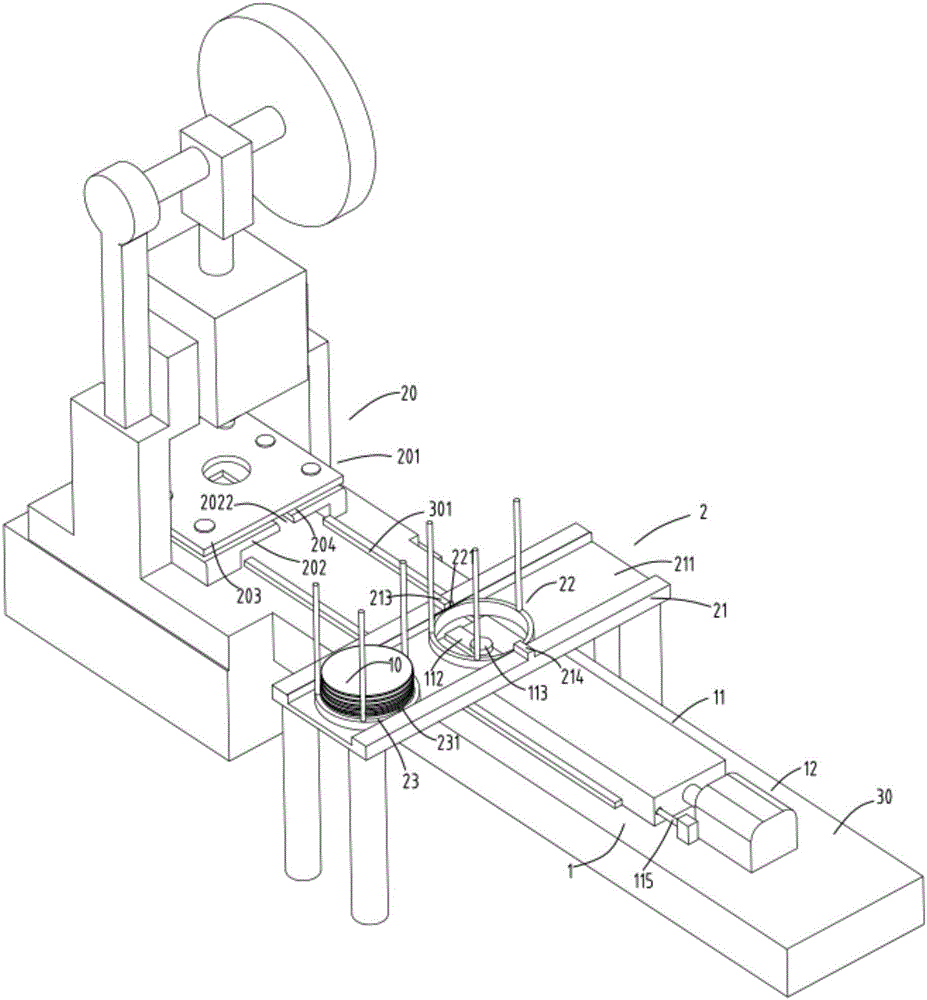

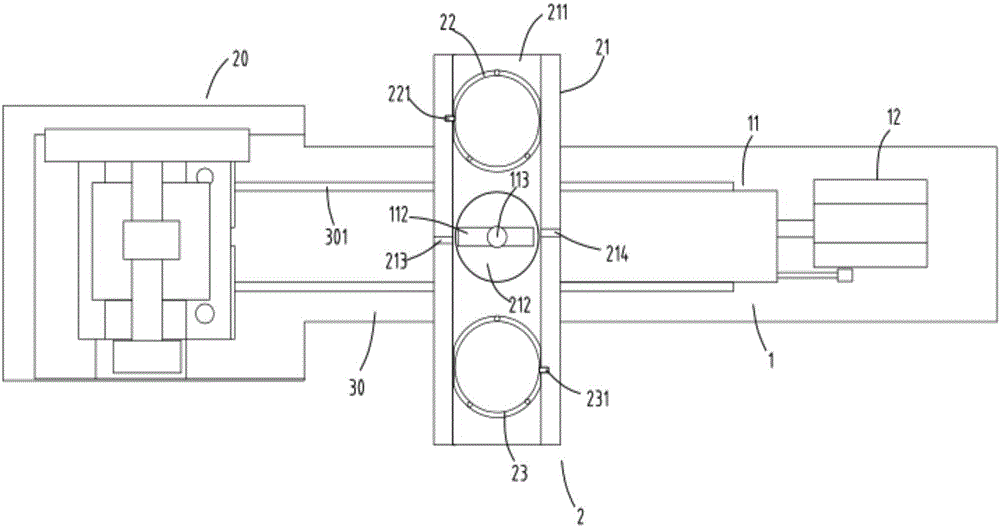

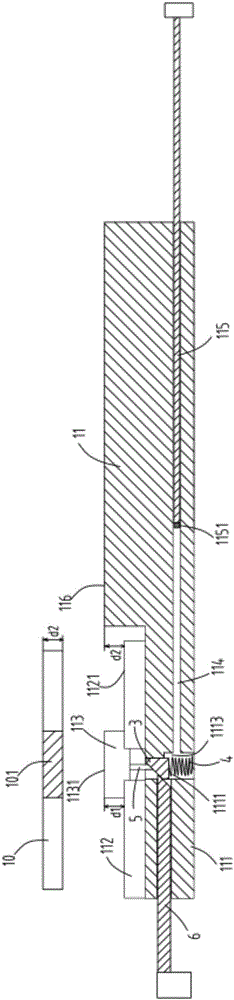

[0027] figure 1 The three-dimensional schematic diagram of the precise and uninterrupted feeding device for the clutch coil shell stamping, figure 2 The top view schematic diagram of the precise and uninterrupted feeding device for the clutch coil shell stamping, image 3 Is a schematic cross-sectional view when the carrier is about to reach the stamping position, Figure 4 Is a schematic cross-sectional view when the carrier reaches the stamping position, Figure 5 Is a schematic cross-sectional view when the carrier is about to return to the feeding position, Image 6 Is a schematic cross-sectional view of the internal structure of the carrier's step position, Figure 7 It is a three-dimensional schematic diagram of part of the structure of the precise and uninterrupted feeding device for the clutch coil shell stamping. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, a clutch coil housing stamping precise and uninterrupted f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com