Modified calcium-based absorbent for absorbing CO2, and preparation method thereof

A calcium-based absorbent and modification technology, applied in the field of CO2 capture, can solve the problem of low anti-sintering performance, achieve the effects of improving anti-sintering performance, reducing mutual contact, and increasing carbonation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

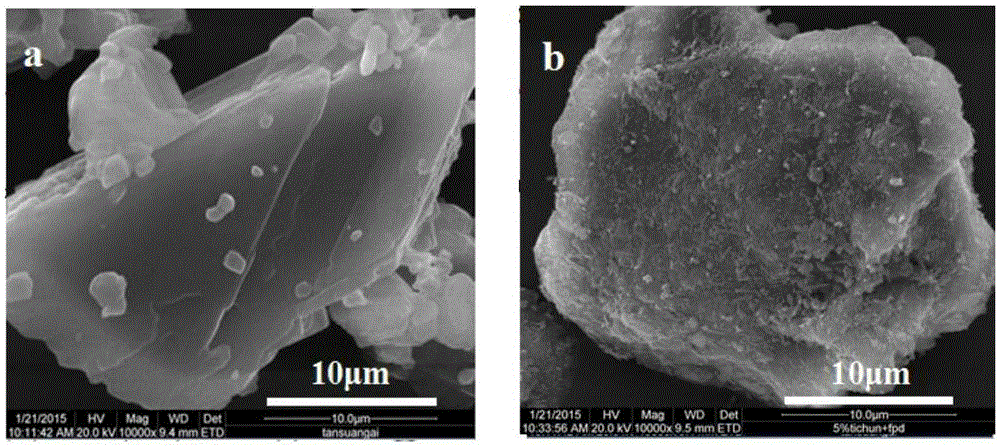

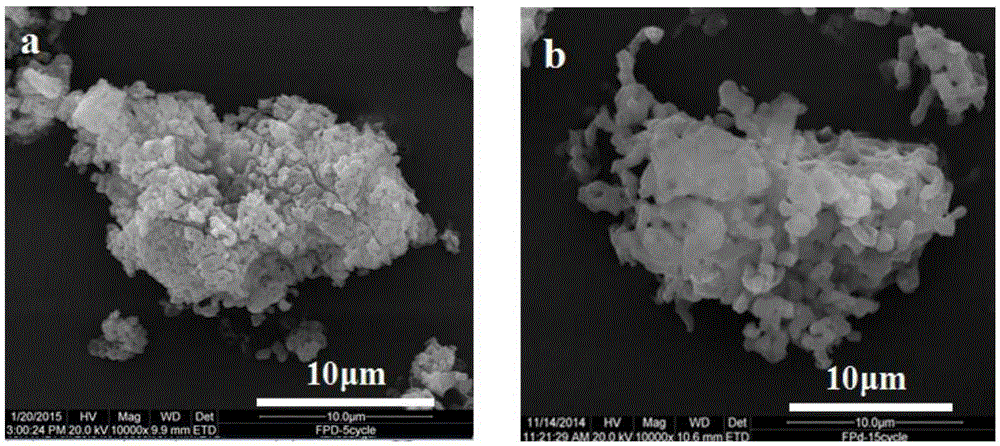

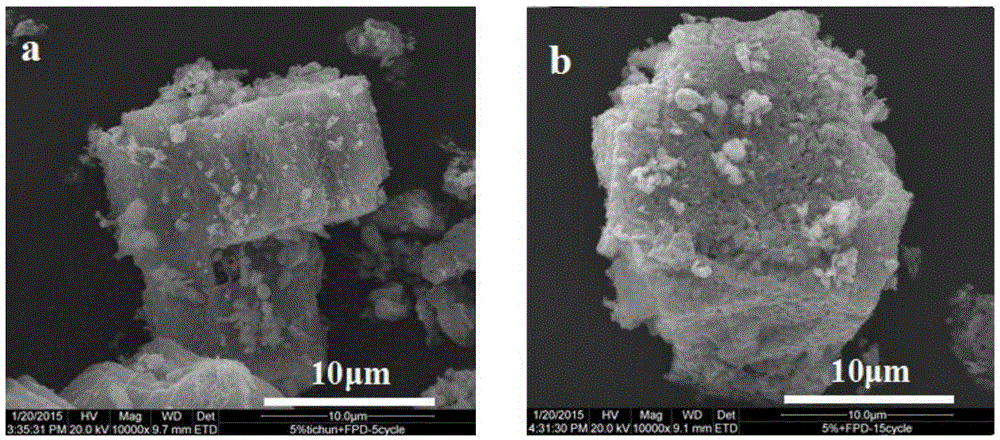

[0028] This embodiment provides a method for absorbing CO 2 The modified calcium-based absorbent includes limestone, and the nanofiber material attached to the surface of the limestone; the nanofiber material accounts for 1%-20% by weight of the modified calcium-based absorbent.

[0029] This modified calcium-based absorbent, with nanofibrous material as an additive, is adsorbed on the surface of limestone and acts as a skeleton, which can effectively reduce the mutual contact between limestone particles and avoid the capture of CO by limestone particles in the cycle. 2 The sintering and fusion between the particles during the process greatly improves the anti-sintering ability of the calcium-based absorbent and greatly improves the carbonation rate; at the same time, the content of nanofiber materials in the modified calcium-based absorbent should not be too high , if it is too high, the content of limestone in the calcium-based absorbent is low, and it itself absorbs CO 2 T...

Embodiment 2

[0033] This embodiment 2 provides a method for absorbing CO provided in embodiment 1 2 The preparation method of the modified calcium-based absorbent, comprising the following steps:

[0034] According to the proportioning relationship between the limestone and the nanofiber material in the above-mentioned embodiment 1, the limestone and the nanofiber material are matched, and then the prepared limestone and the nanofiber material are dissolved in an organic solvent, and after being fully dispersed, the The mixed liquid is dried in an oven, and the modified calcium-based absorbent is prepared after drying.

[0035] Limestone and nanofibrous materials are dissolved in an organic solvent. In view of the fact that nanofibrous materials are easily dispersed in organic solvents, it is convenient for nanofibrous materials to fully adsorb on the surface of limestone; during the entire preparation process, only simple physical mixing and drying, The preparation method is simple, the ...

Embodiment 3

[0052] This embodiment provides a method for absorbing CO 2 The difference between the preparation method of the modified calcium-based absorbent and Example 2 is that the nanofibrous material is purified before the limestone is mixed with the nanofibrous material.

[0053] For example, if attapulgite is used as nanofiber material, attapulgite raw ore is firstly purified, and the purification steps are as follows:

[0054] (1) Weigh 15-20g of natural attapulgite raw ore, 0.3-0.4g of sodium hexametaphosphate, add 1500mL of deionized water, fully disperse, and mechanically stir for 1.5-2 hours;

[0055] (2) The stirred mixed solution is activated in a water bath at 95-100° C. for 2 hours with 1 mol / L hydrochloric acid solution;

[0056] (3) Add 4.5-5 g of EDTA disodium salt to the activated mixed solution, stir it electromagnetically for 1.5-2 hours, centrifuge and wash twice after 24 hours, and recover the solid;

[0057] (4) Add 22-25g of anhydrous Na in the recovered solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com