Cereal cake premixed flour, cereal cake and preparation method thereof

A premixed powder and cake technology, which is applied in the direction of dough preparation, prebaked dough processing, dough/premix, etc., can solve the problem of not many types, achieve full and complete shape, increase water retention, and ensure foaming volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

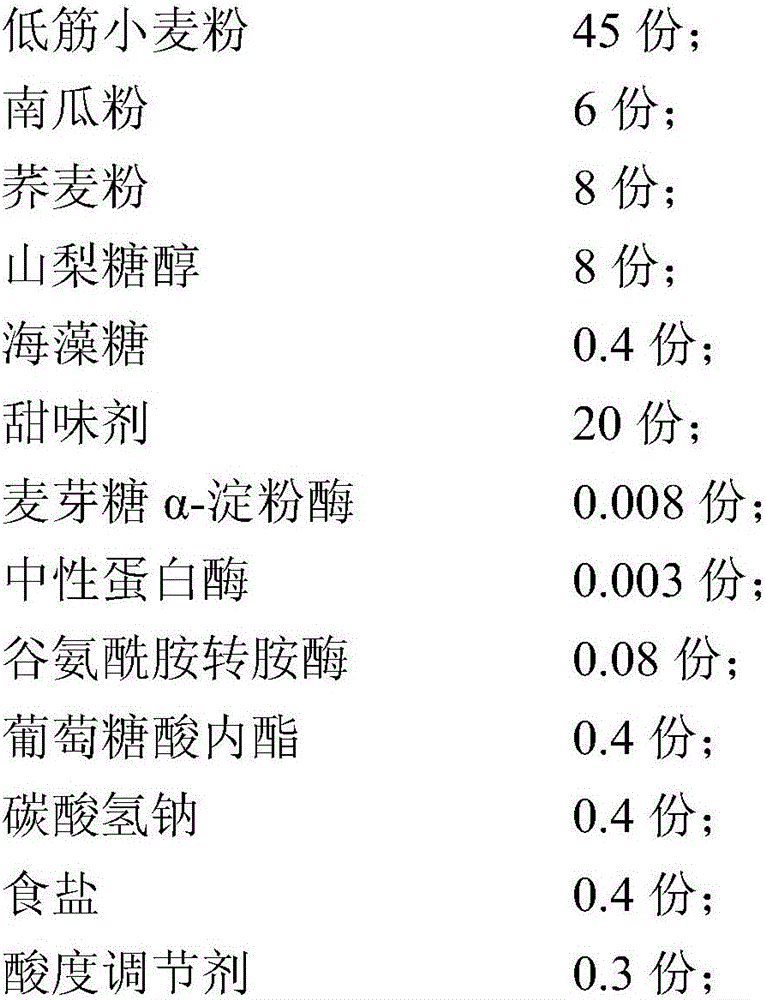

[0051] A multigrain cake premix, comprising the following components in parts by mass:

[0052]

[0053] A preparation method of multigrain cake, comprising the steps of:

[0054] (1) Mix all the components of the above multigrain cake premix evenly to obtain the multigrain cake premix;

[0055](2) Mix the multigrain cake premix powder prepared in step (1) with whole egg liquid and water, and stir evenly at a stirring speed of 20 rpm to obtain a multigrain cake slurry; wherein, the amount of whole egg liquid is 140% of the mass of the powder mix; the amount of water added is 25% of the mass of the multigrain cake premix powder;

[0056] (3) send the miscellaneous grains cake slurry that step (2) makes, the specific gravity of controlling miscellaneous grains cake slurry is 0.31;

[0057] (4) under the condition of stirring (stirring speed of 20rpm), add corn oil at a speed of 7ml / s in the miscellaneous grain cake slurry sent in step (3), and control the proportion of the ...

Embodiment 2

[0061] A multigrain cake premix, comprising the following components in parts by mass:

[0062]

[0063] A preparation method of multigrain cake, comprising the steps of:

[0064] (1) Mix all the components of the above multigrain cake premix evenly to obtain the multigrain cake premix;

[0065] (2) Mix the multigrain cake premix powder prepared in step (1) with whole egg liquid and water, and stir evenly at a stirring speed of 15 rpm to obtain a multigrain cake slurry; wherein, the amount of whole egg liquid is 130% of the mass of the powder mix; the amount of water added is 30% of the mass of the multigrain cake premix powder;

[0066] (3) send the miscellaneous grains cake slurry that step (2) makes, the specific gravity of controlling miscellaneous grains cake slurry is 0.31;

[0067] (4) under the condition of stirring (stirring speed of 15rpm), add corn oil at a speed of 6ml / s in the miscellaneous grain cake slurry sent in step (3), and control the proportion of the...

Embodiment 3

[0071] A multigrain cake premix, comprising the following components in parts by mass:

[0072]

[0073] A preparation method of multigrain cake, comprising the steps of:

[0074] (1) Mix all the components of the above multigrain cake premix evenly to obtain the multigrain cake premix;

[0075] (2) Mix the multigrain cake premix powder prepared in step (1) with whole egg liquid and water, and stir evenly at a stirring speed of 25 rpm to obtain a multigrain cake slurry; wherein, the amount of whole egg liquid is 160% of the mass of the powder mix; the amount of water added is 20% of the mass of the multigrain cake premix powder;

[0076] (3) send the miscellaneous grains cake slurry that step (2) makes, the specific gravity of controlling miscellaneous grains cake slurry is 0.32;

[0077] (4) under the condition of stirring (stirring speed of 25rpm), add soybean oil at a speed of 8ml / s in the miscellaneous grain cake slurry sent in step (3), and control the proportion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com