Large target surface high-precision optics heat-free temperature measurement lens and adjustment method

A high-precision, large-target technology, used in optical radiometry, radiation pyrometry, optics, etc., can solve the problem that the imaging field angle is small and cannot fully obtain the overall structure, concentricity, accuracy and axial position of the test object. Accuracy, optical system focal length change and other issues, to achieve the effect of reasonable lens design, wide-spectrum confocal, and clear imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

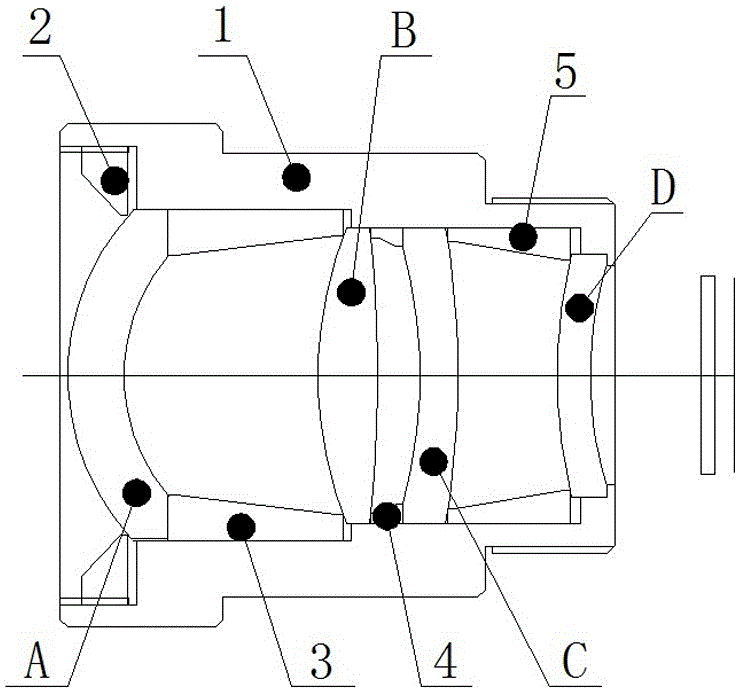

[0023] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

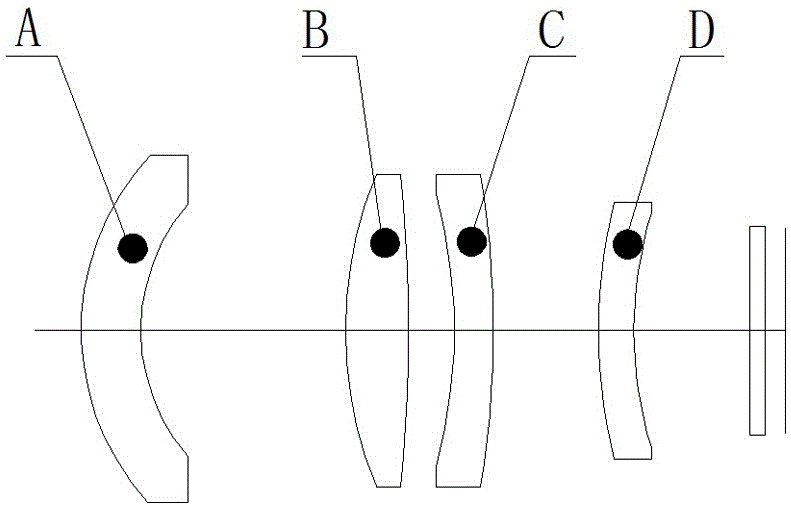

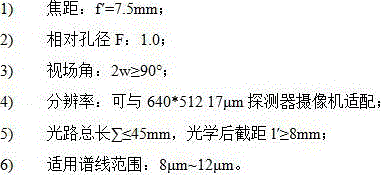

[0024] Such as Figure 1~2 As shown, a high-precision optical athermalization temperature measurement lens with a large target surface includes a negative crescent lens A, a biconvex lens B, a negative crescent lens C, and a negative crescent lens D arranged in sequence along the incident direction of light from left to right.

[0025] In the embodiment of the present invention, the air gap between the negative crescent lens A and the biconvex lens B is 13mm, the air gap between the biconvex lens B and the negative crescent lens C is 3mm, and the negative crescent lens C and the The air space between the negative crescent lenses D is 7mm.

[0026] In the embodiment of the present invention, the material of the negative crescent lens A, biconvex lens B, negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com