A diamond wire saw production line

A diamond wire saw and production line technology, applied in the direction of electrolytic coating, coating, electrolytic process, etc., can solve the problems of easy blockage of wire holes, slow production line speed, easy wire breakage, etc., so as to overcome jitter and wire breakage. phenomenon, improve the traveling speed, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

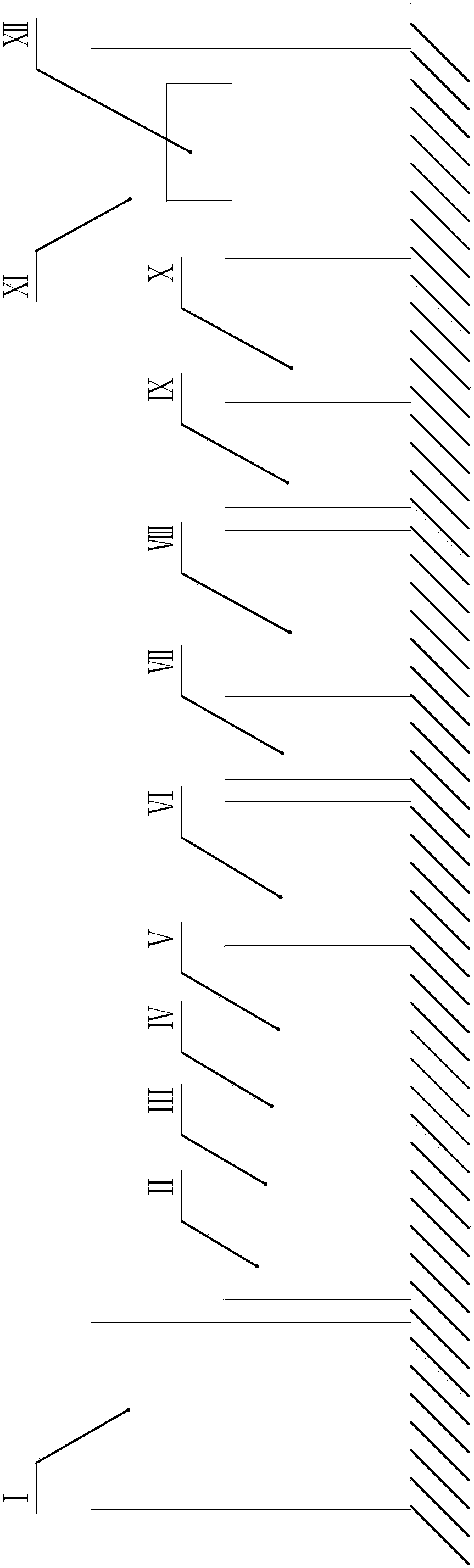

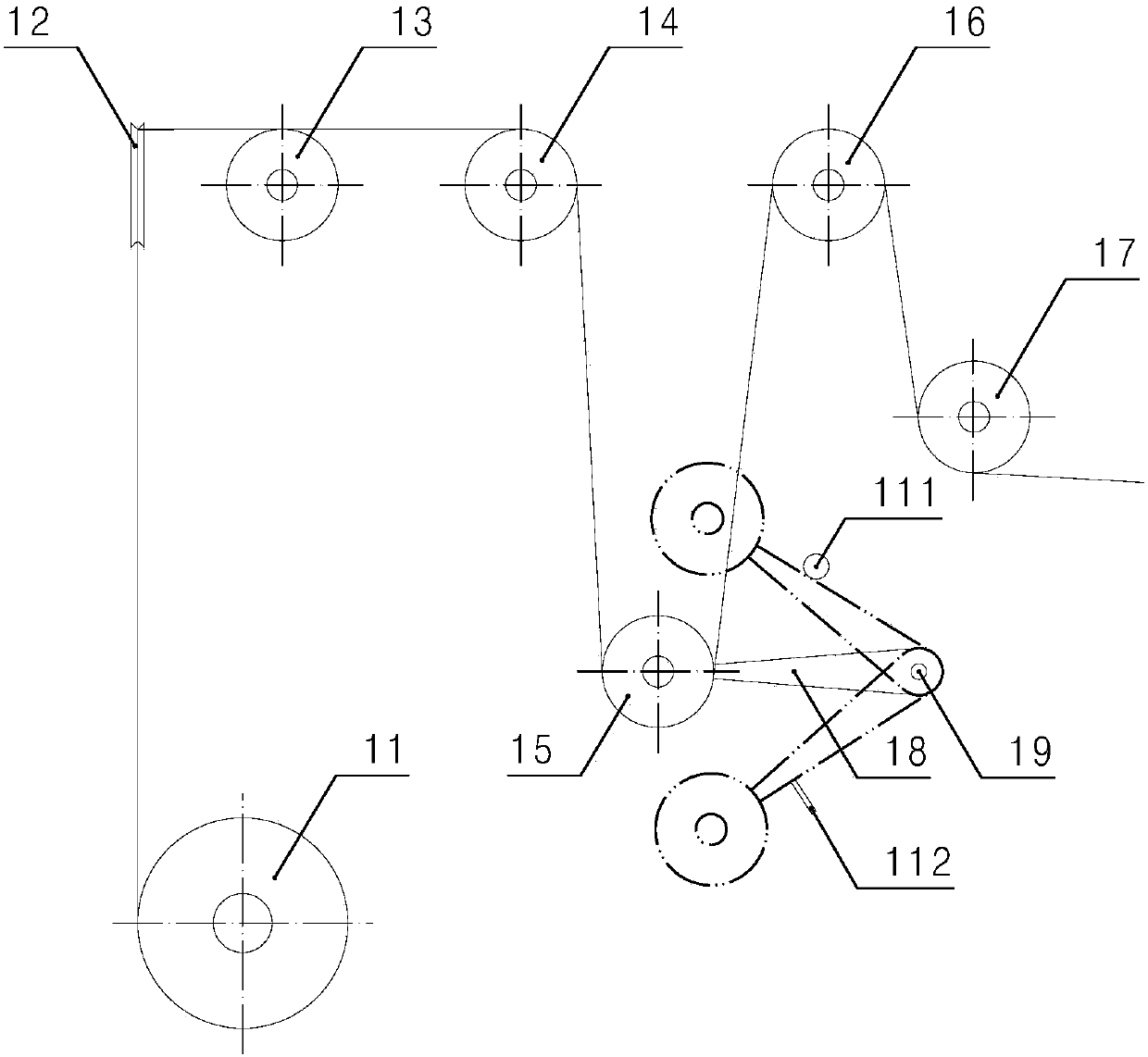

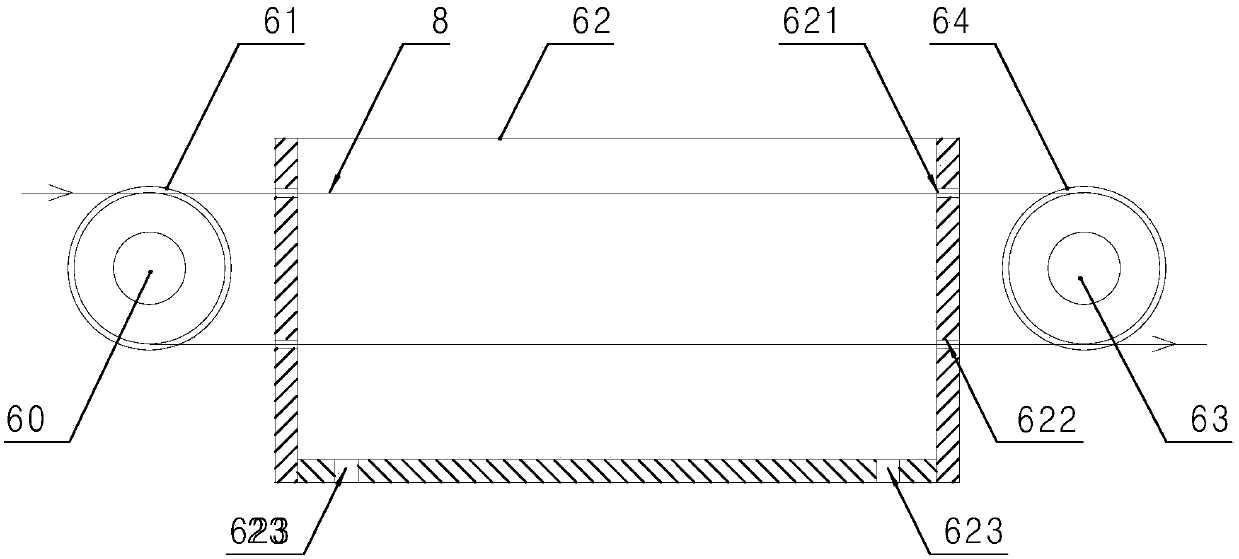

[0025] Attached below Figures 1 to 7 , to describe in detail the specific implementation of a diamond wire saw production line according to the present invention.

[0026] Such as figure 1 As shown, the diamond wire saw production line according to the present invention has a structure comprising: along the direction of travel of the metal wire used for electroplating diamond micropowder, a wire-releasing device I, an alkali cleaning device II, a water washing device III before pickling, an acid Washing device IV, water washing device before sand loading V, sand loading device VI, water washing device after sand loading VII, sand fixing device VIII, water washing device after sand fixing IX, drying device X, wire take-up device XI, and wire take-up device XI Equipped with real-time monitoring device Ⅻ (alkali washing device Ⅱ, water washing device before pickling III, pickling device Ⅳ, water washing device before sanding Ⅴ, water washing device after sanding Ⅶ, sand fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com