Focusing mechanism and lens comprising same

A focusing and lens barrel technology, used in installation, optics, instruments, etc., can solve problems such as poor performance, and achieve the effect of ensuring service life, large focusing range, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

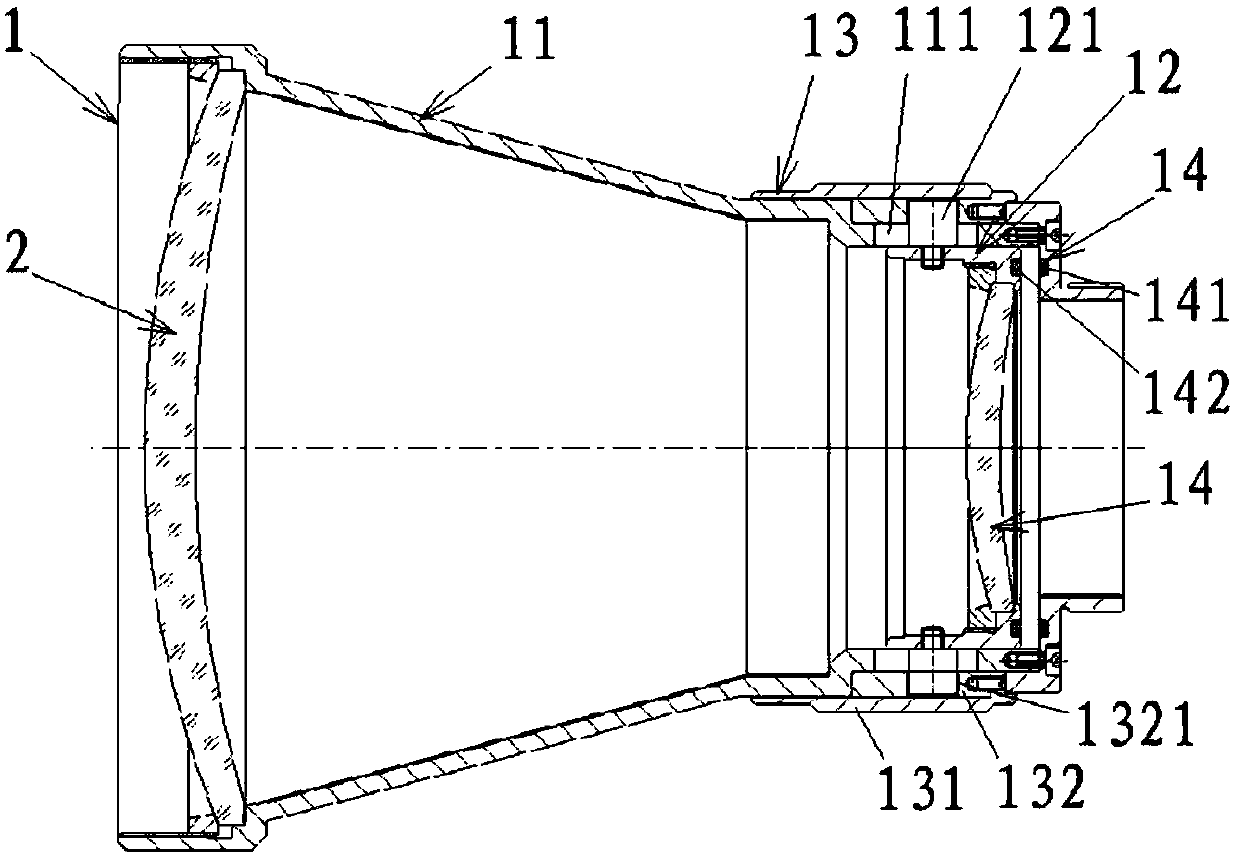

[0038] Such as figure 1 As shown, according to an embodiment of the present invention, the lens of the present invention includes: a focusing mechanism 1 , a first lens group 2 and a second lens group 3 . In this embodiment, the first lens group 2 and the second lens group 3 are installed on the focusing mechanism 1 respectively. The adjustment of the distance between the first lens group 2 and the second lens group 3 is realized through the adjustment function of the focus adjustment mechanism 1 , thereby realizing the focus adjustment of the lens of the present invention.

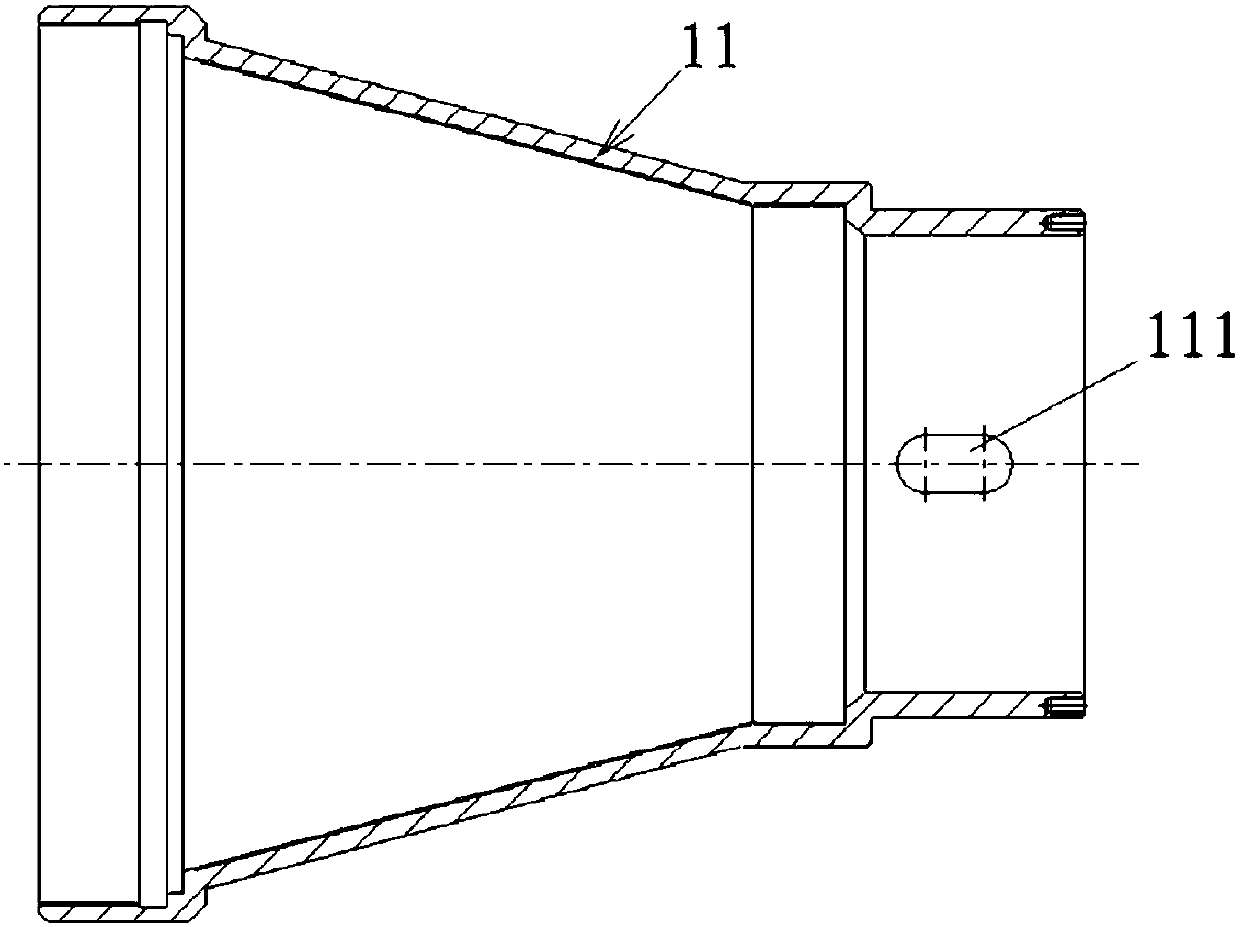

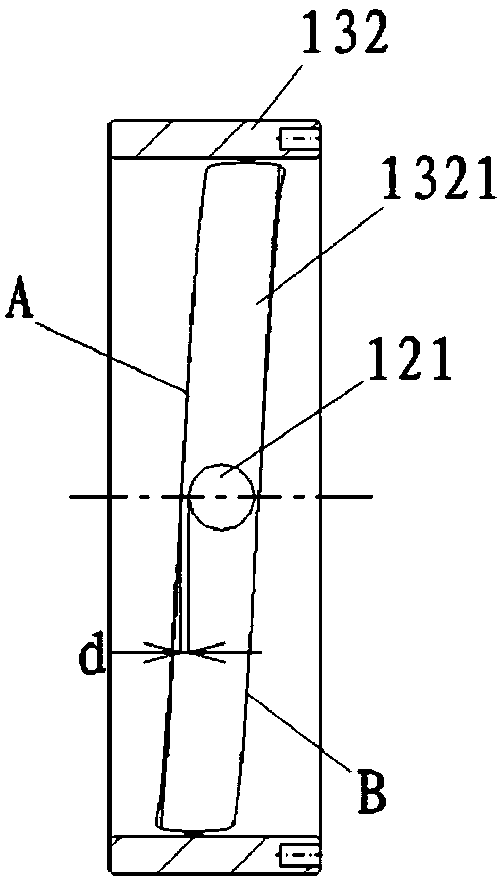

[0039] Such as figure 1 As shown, according to an embodiment of the present invention, the focusing mechanism 1 of the present invention includes: a first lens barrel 11 , a second lens barrel 12 , an adjustment assembly 13 and a force application assembly 14 . In this embodiment, the second lens barrel 12 is slidably connected with the first lens barrel 11 . The aperture of the first lens barrel 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com