Method for determining content of calcium in calcium-silicon alloy by potentiometric titration

A calcium-silicon alloy and potentiometric titration technology, which is applied in the field of chemical analysis, can solve problems such as harsh conditions of use, high detection costs, and short service life, and achieve the goals of reducing analysis costs, improving precision and accuracy, and shortening the analysis cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

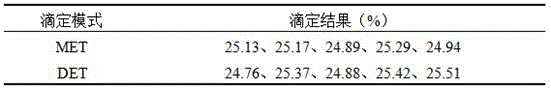

Examples

Embodiment

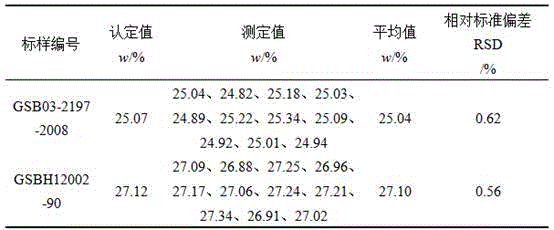

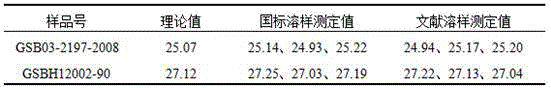

[0037] Take silicon-calcium alloy standard samples GSB03-2197-2008 and GSBH12002-90 for testing.

[0038] Specifically include the following steps:

[0039] 1. Sample treatment: first calibrate the concentration of EDTA with calcium standard solution, and then take 0.025 mol / L CuSO 4 Put 10 mL of the solution in a beaker, add 10 mL of ammoniacal ammonium chloride buffer solution, and titrate CuSO with EDTA 4 To the end point, record the volume V mL, and then take 0.025 mol / L CuSO 4 Solution 10mL was placed in a beaker, and V mL of EDTA was quantitatively added to form a 1:1 CuEDTA solution.

[0040] Weigh 0.1000 g of samples respectively and place them in a polytetrafluoroethylene beaker, add 10 mL of nitric acid, and drop about 5 mL of hydrofluoric acid. Decompose while cooling with water. After the violent reaction stops, add 10 mL of perchloric acid, evaporate until white fumes of perchloric acid appear, and concentrate its volume to about 1 mL.

[0041]Remove the polyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com