A prefabricated concrete urban comprehensive pipe gallery structure and construction method

A comprehensive pipe gallery and prefabricated assembly technology, applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of high construction cost, difficult construction, and increased water seepage rate of nodes, so as to reduce the construction period and improve Improve construction efficiency and improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

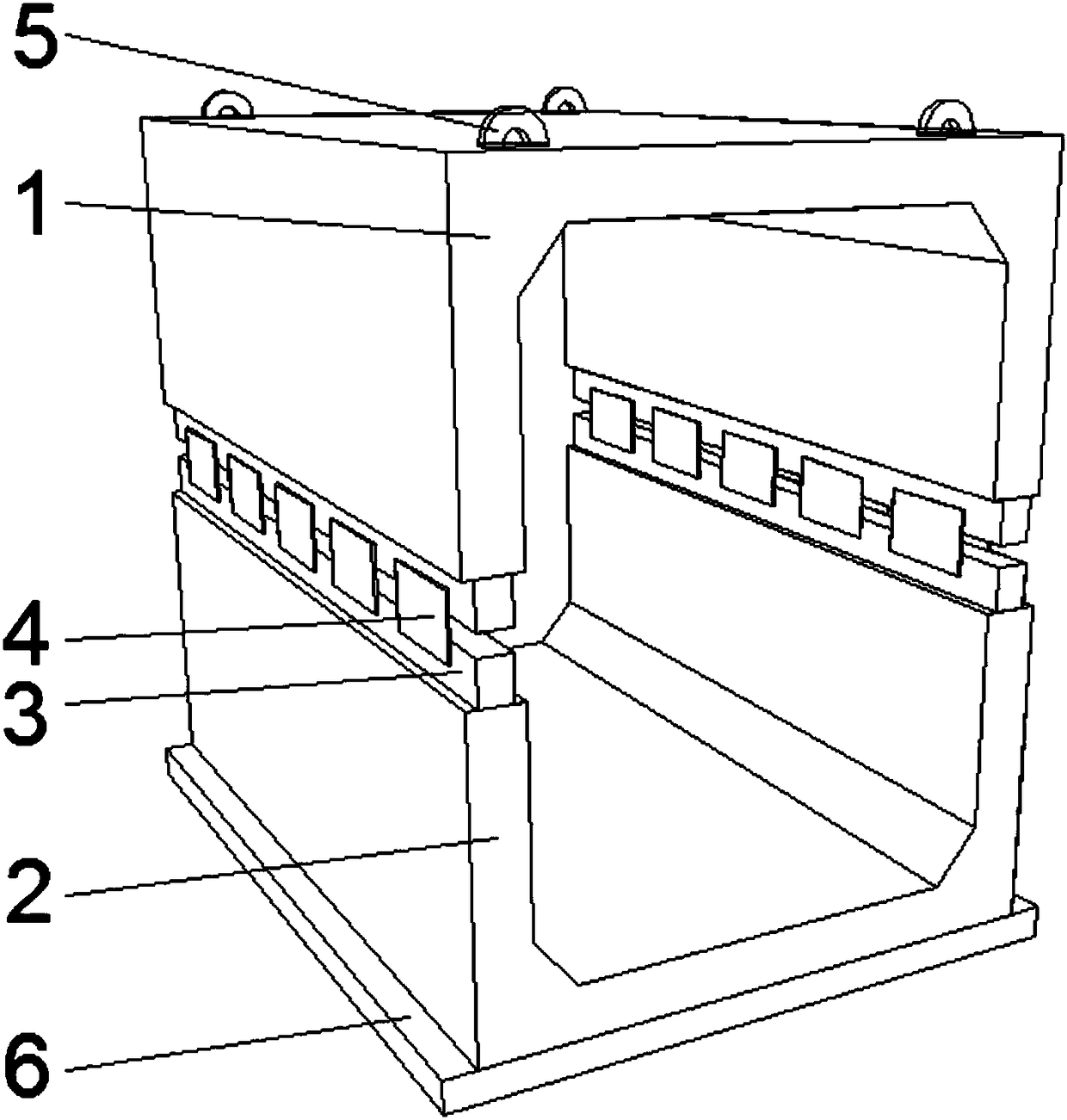

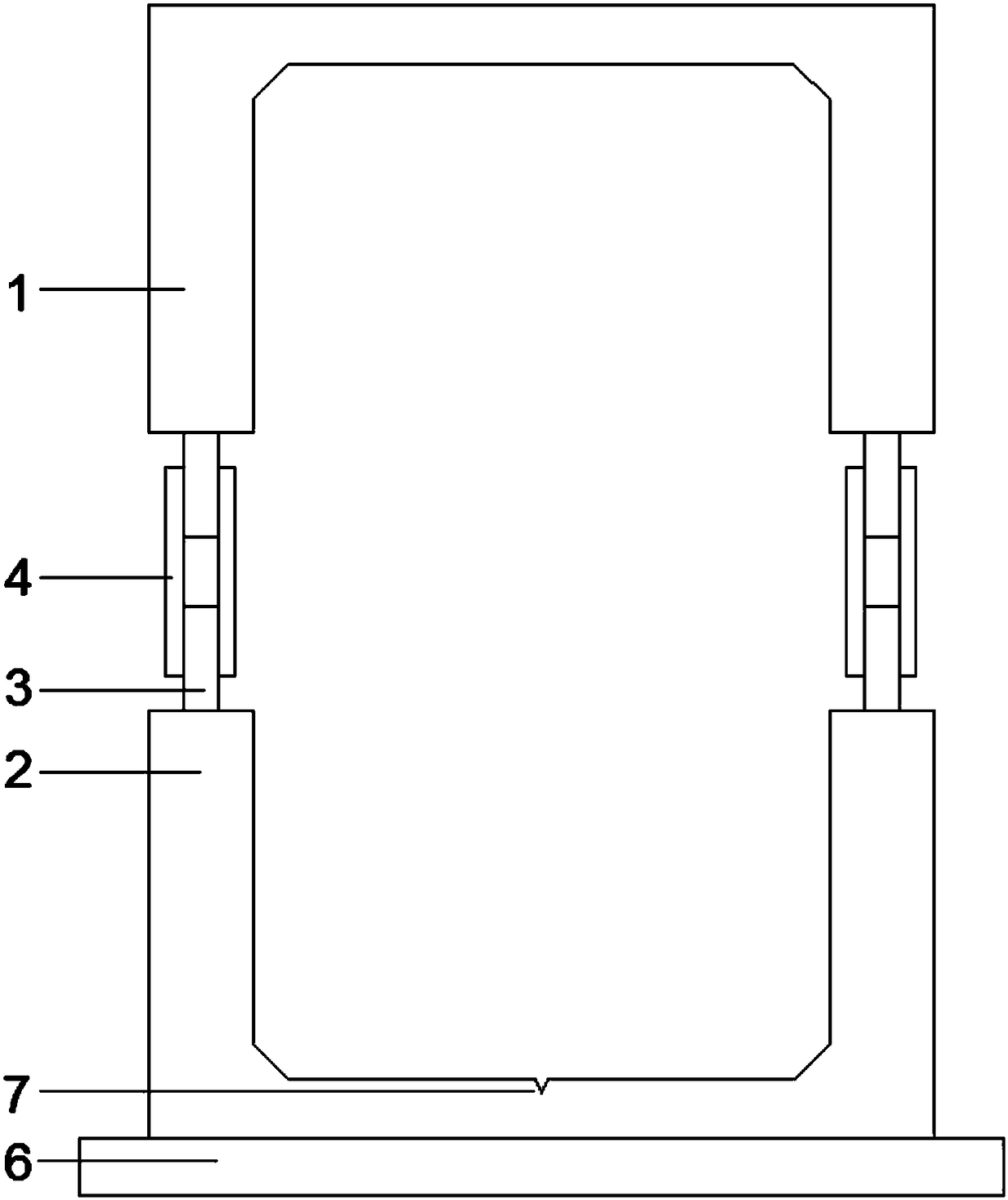

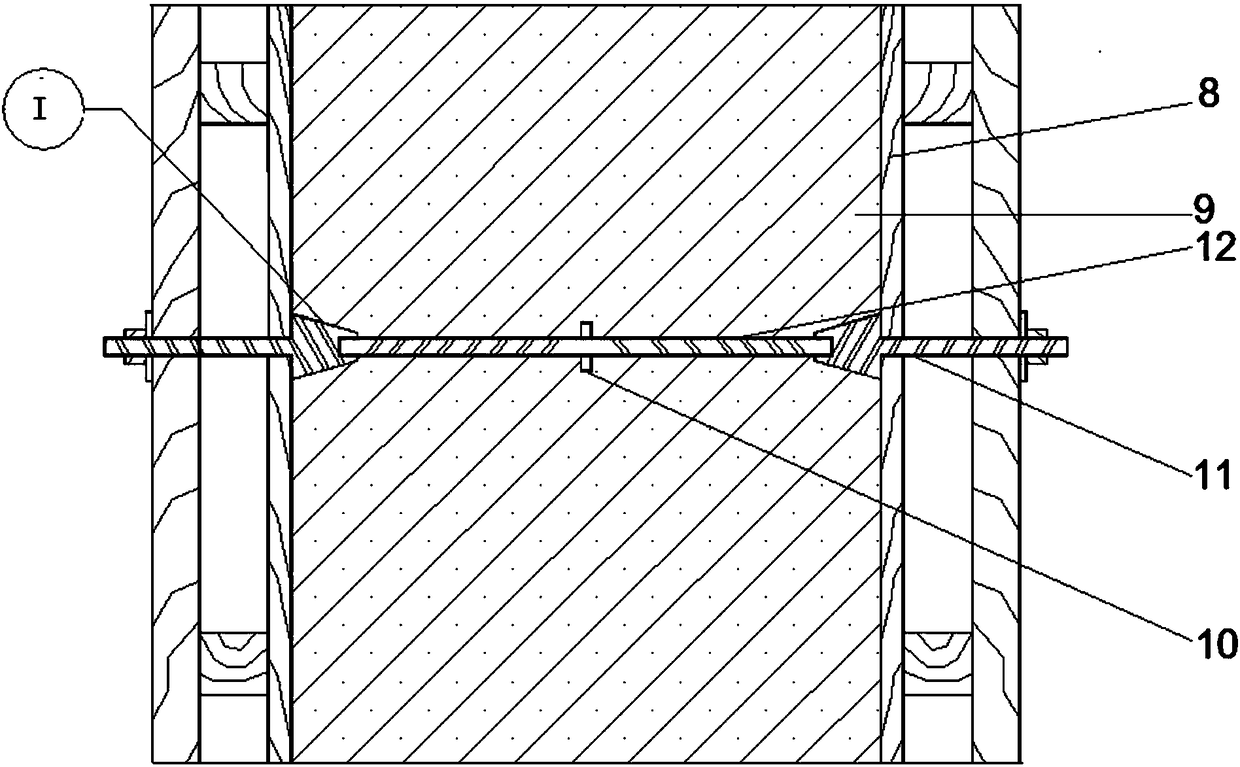

[0022] Refer to attached Figure 1-3 , the specific embodiment of the present invention includes an inverted U-shaped prefabricated pipe gallery 1 on the upper side and a positive U-shaped prefabricated pipe gallery 2 on the lower side, the left and right vertical plates of the positive U-shaped prefabricated pipe gallery and the left and right vertical plates of the inverted U-shaped prefabricated pipe gallery. , the ends of the right vertical plate are respectively embedded with rectangular steel pipes 3, part of the rectangular steel pipes are built-in, and some of the ends of the vertical plate are externally placed. Concrete grouting material, there is a central longitudinal drainage ditch 7 in the middle of the upper surface of the bottom of the U-shaped prefabricated pipe gallery. If the slope is increased in areas with frequent precipitation, four pre-buried Annular lifting lugs 5 are convenient for installation and transportation. When assembling the comprehensive pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com