Process for enzymatic preparation of gelatin

An enzymatic preparation and gelatin technology, applied in the direction of fermentation, etc., can solve the problem of not meeting the requirements of gelatin for capsules, and achieve the effects of reducing the workload of sewage treatment, improving efficiency, and reducing construction investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

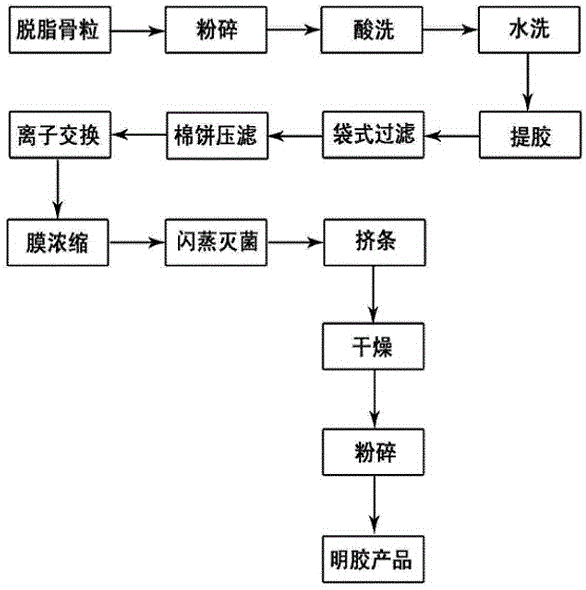

[0029] Such as figure 1 Shown, bioenzyme method manufactures gelatin industrialized production process for capsule, comprises the following steps:

[0030] S1: Bone particle pulverization: use a special pulverizer to pulverize the selected defatted bone particles to a bone meal below 8 mesh;

[0031] S2: Pickling: Send the bone meal below 8 mesh into 30m at the water-to-material ratio of 3:1 3 In the pickling tank, add hydrochloric acid with a mass concentration of 5% to adjust the pH value to 1-2.5, and stir to clean the bone powder to remove calcium and other impurities. The stirring speed is 20~40r / min, and soak for 6-10h The decanter centrifuge separates the bone, and the solid matter settled on the inner wall of the drum is discharged from the solid phase (ostein) outlet through the screw pusher installed in the inner cavity of the drum, and the liquid phase in the center of the drum passes through the rotating drum. The liquid phase (calcium water) overflow port instal...

Embodiment 2

[0040] Such as figure 1 Shown, bioenzyme method manufactures gelatin industrialized production process for capsule, comprises the following steps:

[0041] S1: Bone particle pulverization: use a special pulverizer to pulverize the selected defatted bone particles to a bone meal below 80 mesh;

[0042] S2: Pickling: Send the bone meal below 80 mesh into 40m at the water-to-material ratio of 5:1 3 In the pickling tank, add hydrochloric acid with a mass concentration of 12% to adjust the pH value to 1-2.5, and stir to clean the bone powder to remove calcium and other impurities. The stirring speed is 100r / min; after soaking for 8-10h, settle and centrifuge The machine separates the bone, and the solid matter settled on the inner wall of the drum is discharged from the drum through the screw pusher installed in the inner cavity of the drum from the solid phase (ostein) outlet, and the liquid phase in the center of the drum passes through the drum. The set liquid phase (calcium w...

Embodiment 3

[0051] Such as figure 1 Shown, bioenzyme method manufactures gelatin industrialized production process for capsule, comprises the following steps:

[0052] S1: Bone particle pulverization: use a special pulverizer to pulverize the selected defatted bone particles to a bone meal below 120 mesh;

[0053] S2: Pickling: send the bone meal below 120 mesh into 20m 3 Add phosphoric acid with a mass concentration of 15% to the special pickling tank, adjust the pH value to 1-2.5, and stir to clean the bone meal to remove calcium and other impurities. The stirring speed is 200r / min, soak for 6-10h and then settle The centrifuge separates the bone, and the solid matter settled on the inner wall of the drum is discharged from the solid phase (ostein) outlet through the screw pusher installed in the inner cavity of the drum, and the liquid phase in the center of the drum passes through the drum. The liquid phase (calcium water) overflow port set in the body is discharged out of the drum;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com