A kind of alkalophilic bacillus ntt33c6 producing constitutive mannanase and its application

A technology of NTT33C6 and alkalophilic bacillus, applied in the field of microorganisms, can solve the problems of high production cost, high processing cost, high consumption of raw materials and energy consumption, etc., achieve high production stability, avoid secondary pollution, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

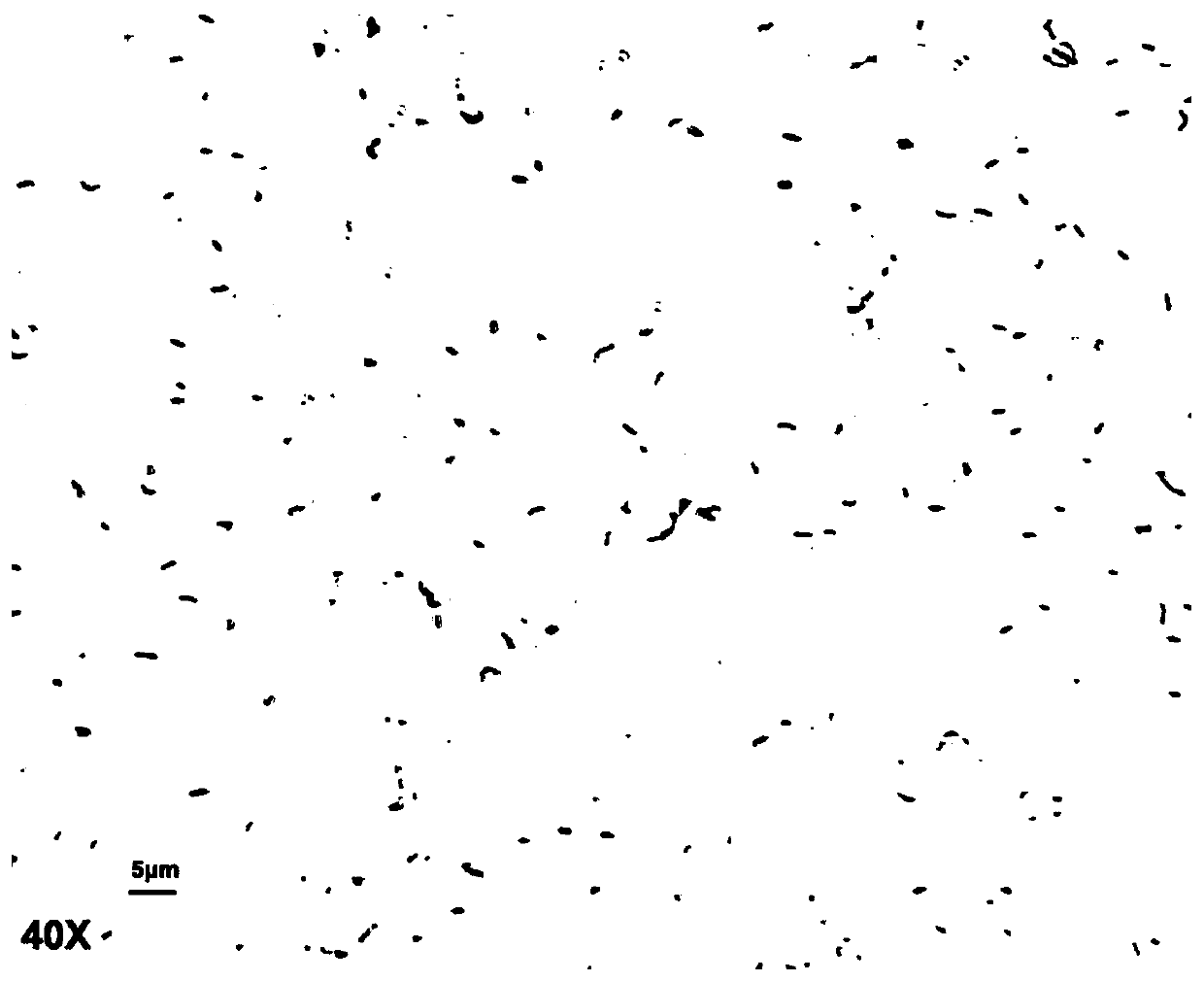

[0053] The isolation and screening method of alkalophilic bacillus NTT33C6, its steps are:

[0054] 1) Sample collection

[0055] Soil sampling was carried out from the Zhelimu League area of Inner Mongolia Autonomous Region, China. 1g of the soil sample was suspended in sterile water and mixed evenly; the supernatant was put into the separation medium, and its composition was: glucose 10g, peptone 5g, yeast extract 5g, K 2 HPO 4 1g, MgSO 4 ·7H 2 O 0.2g, agar 18g, water 1000mL, with Na 2 CO 3 Adjust the pH to 10-11; incubate at 28°C for 24-48 hours.

[0056] 2) Separation and purification

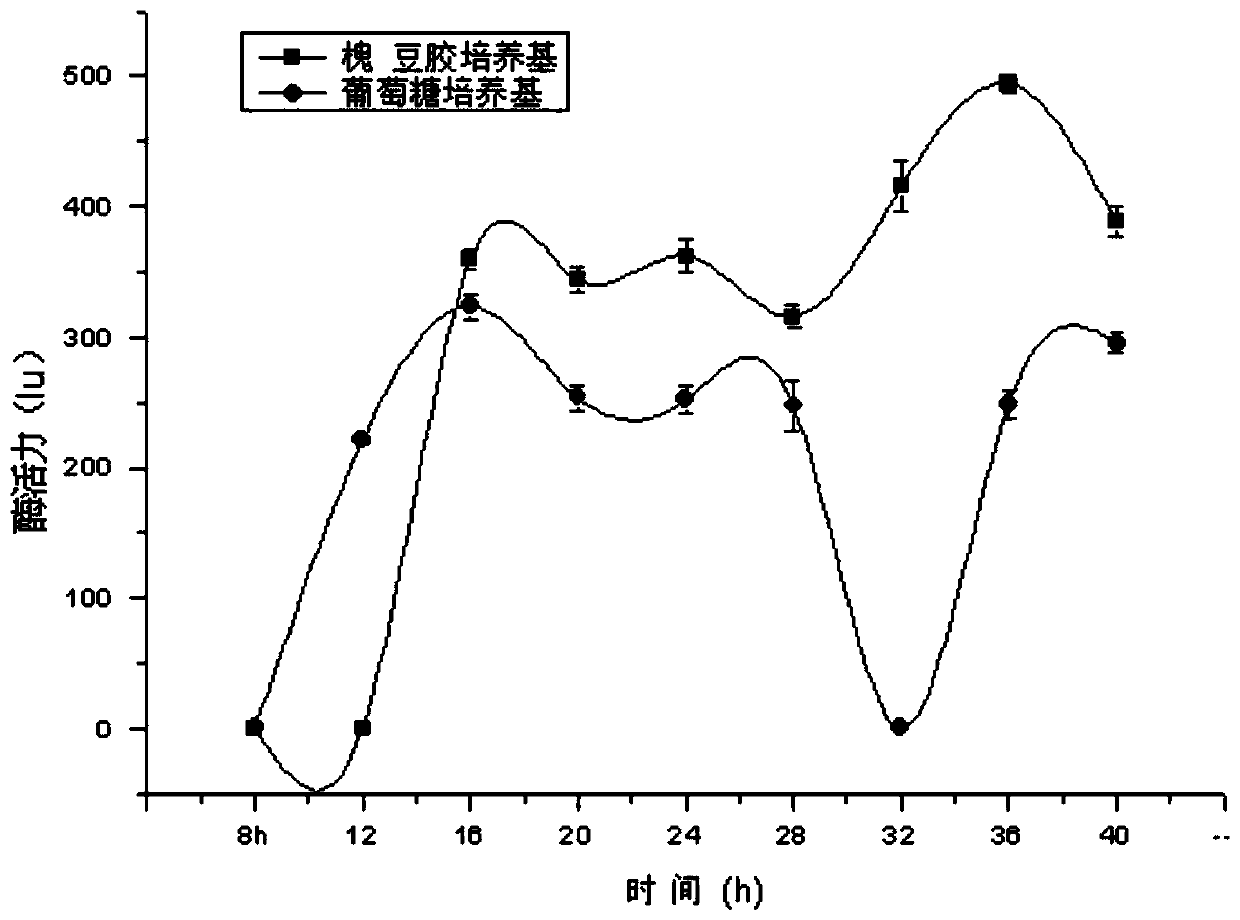

[0057] Select a single colony in the isolation medium and transfer it to the locust bean gum solid medium, the composition of which is locust bean gum 10g, yeast extract 5g, peptone 5g, K 2 HPO 4 1g, MgSO 4 ·7H 2O 0.1g, agar 18g, water 1000mL, with Na 2 CO 3 Adjust the pH to 10-11; select the bacterial strains that produce a transparent circle around the colony, and place th...

Embodiment 2

[0076] The application and effect analysis of Bacillus alkalophilus NTT33C6 in the biological degumming of cannabis, the steps are:

[0077] 1) The obtained mutant strain NTT33C6 was cultured in locust bean gum liquid medium at 37°C, 200 rpm, and activated for 36-48 hours;

[0078] 2) transfer to the culture medium containing hemp respectively, shake at 37°C, 200rpm, and cultivate for 6-8 hours; 4 ) 2 SO 4 1.5g, K 2 HPO 4 0.2g, MgSO 4 ·7H 2 O0.25g, water 150mL, and use Na 2 CO 3 Adjust pH to 10-11;

[0079] 3) Observe the fiber dispersion in the culture medium, measure the residual glue rate, and analyze the lipid waxy, water-soluble, pectin, hemicellulose, lignin and cellulose content of the hemp raw hemp and the fiber after biological degumming [Chinese people Republic "Quantitative Analysis Method for Chemical Components of Ramie" (GB5889-86)]. Its measurement method and calculation formula are as follows:

[0080] ①Determination of moisture content of raw hemp ...

Embodiment 3

[0140] The application of alkalophilic bacillus NTT33C6 in cannabis production, its steps are:

[0141] 1) carry out biological degumming to cannabis according to the method described in step 1) and 2) in Example 2;

[0142] 2) The hemp after biological degumming is dispersed like cotton, after washing the hemp once, in a solution containing 0.2-0.4% mass concentration of NaOH and 0.1% mass concentration of sodium tripolyphosphate, 0.2Mpa, scouring 1-2 Hour.

[0143] 3) According to the general treatment method of chemical degumming (Jingang. Research progress of hemp degumming method [J]. Journal of Nanjing Forestry University, 2009, 33 (4): 140-144.) Washing, beating hemp, bleaching (available chlorine 0.5-0.8g / L), water washing, pickling (pH2.5), water washing, drying, oiling, drying, and drying to obtain fine-dried hemp fiber that meets national quality standards and production needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com