Polyvinyl-based micro/nano ZnO composite material and preparation technology thereof

A technology of composite materials and polyethylene, applied in the direction of nanotechnology, can solve the problems of large micron particle size, small specific surface area, high surface activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, but are not limited thereto. Any modification or equivalent replacement of the technical solutions of the present invention without departing from the spirit and scope of the technical solutions of the present invention shall be included in the present invention. within the scope of protection.

[0035] The polyethylene-based micro / nano ZnO composite material provided by the invention uses low-density polyethylene as the matrix material, adopts nano-zinc oxide and micro-zinc oxide as additives, and is prepared by a two-step melt blending method. The specific preparation steps are as follows:

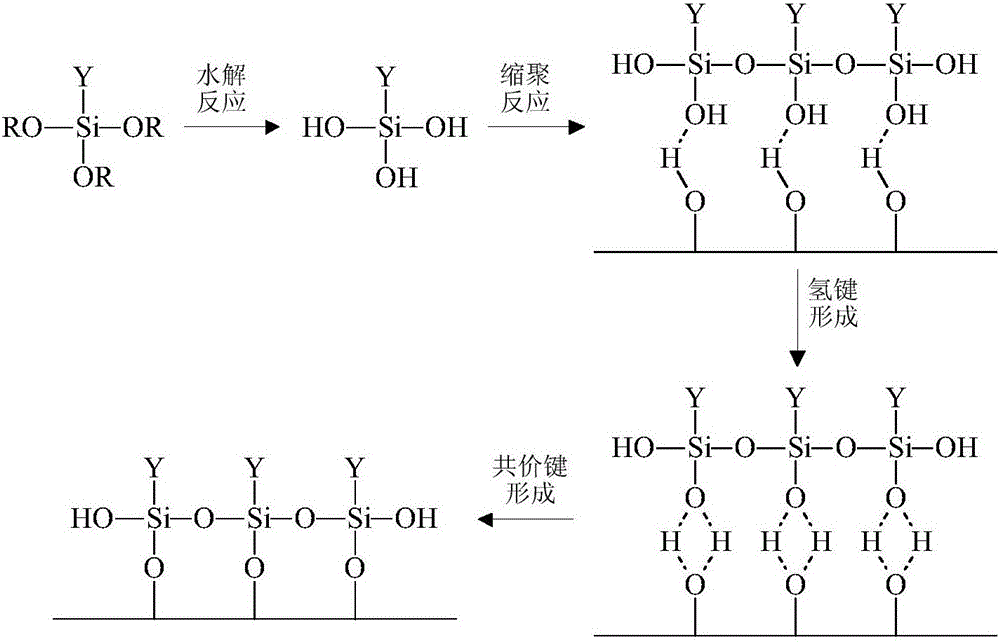

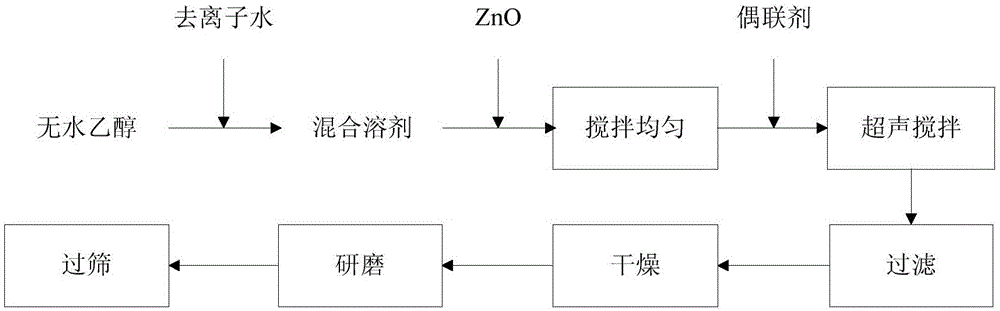

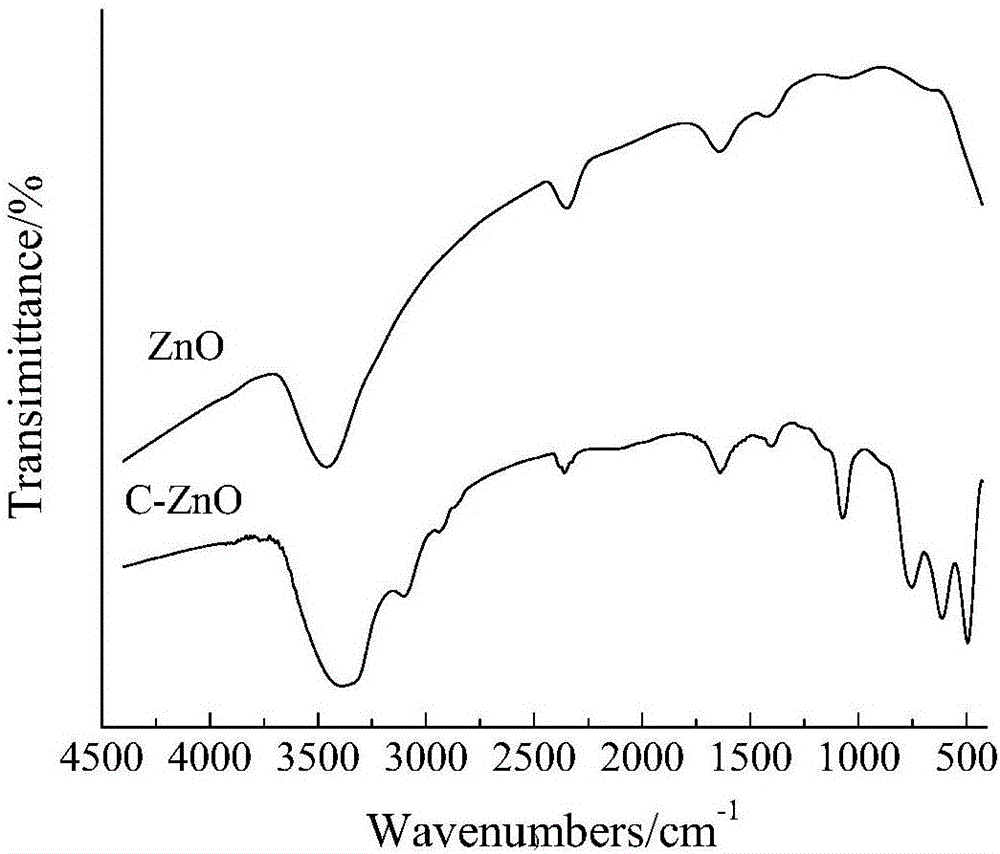

[0036] 1. Surface modification of nano-zinc oxide

[0037] As a new functional inorganic product, nano-zinc oxide has great surface energy, extremely high surface activity and extremely strong polarity. When added to organic polyethylene, poor compatibil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com