Coated glass with dual functions of highly reflecting visible light and blocking infrared rays and preparation method thereof

A technology of coated glass and reflective glass, which is applied in the field of dual-functional coated glass with high reflection of visible light and cut-off infrared rays and its preparation, to achieve the effects of energy saving, high reflectivity of visible light and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

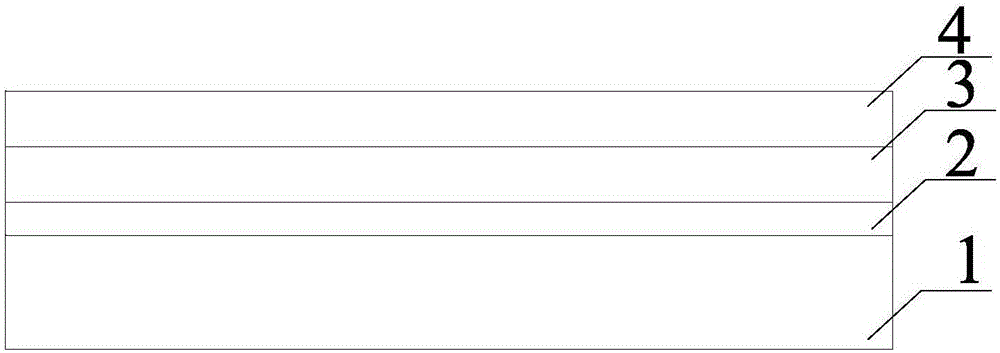

[0032] Such as figure 1 As shown, it is a dual-function coated glass with high visible light reflection and infrared cutoff provided in this embodiment. The dual-function coated glass includes a glass substrate 1 and a near-middle infrared reflection layer and a visible light enhanced reflection layer 4 sequentially arranged on the surface of the glass substrate 1 . In this embodiment, the near-middle infrared reflective layer includes an isolation layer 2 and a transparent conductive semiconductor layer 3 in sequence, and the isolation layer 2 is SiO x film layer, wherein x=1-2, the refractive index of the isolation layer 2 is 1.44-1.48; the transparent conductive semiconductor layer 3 is ITO, ATO, AZO, GZO or ZnO-SiO 2 Any one of the film layers; the visible light enhanced reflection layer 4 includes SiO arranged alternately in sequence x film layer and high refractive index medium film layer, wherein x=1-2, the SiO xThe refractive index of the film layer is 1.44-1.48; th...

Embodiment 2

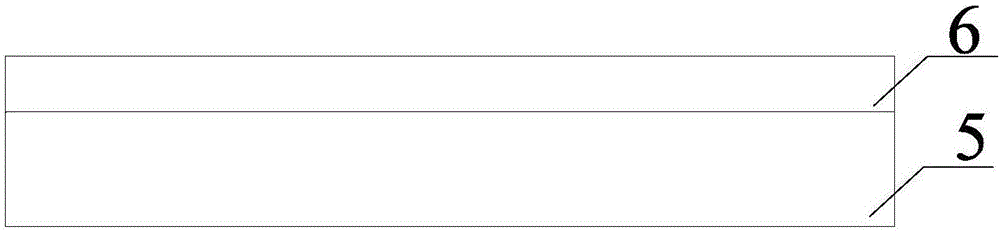

[0035] Such as figure 2 As shown, it is a dual-function coated glass with high visible light reflection and infrared cutoff provided in this embodiment. The dual-function coated glass includes a float FTO glass substrate 5 and a visible light enhanced reflection layer 6 arranged on the surface of the float FTO glass substrate 5 .

Embodiment 3

[0037] This embodiment provides a method for preparing a dual-functional coated glass with high reflection of visible light and cut-off infrared rays, including the following steps:

[0038] 1. Glass cleaning: use deionized water to clean the glass and dry it to obtain clean glass;

[0039] 2. Put the clean glass in the vacuum box of sputtering coating, and treat the glass surface with plasma formed by 500-1000V voltage under the atmospheric pressure nitrogen, and then pump the air pressure of the vacuum box to (3.5-8.5)× 10 -4 Pa;

[0040] 3. Adopt the method of magnetron sputtering to plate the isolation layer, the near-middle infrared reflection layer and the visible light enhanced reflection layer on the glass surface sequentially. The specific operation is as follows:

[0041] 1) Plating isolation film system SiO x Film layer, where X=1-2: In the vacuum box, the flow ratio of oxygen and argon is 5-15%, and the sputtering pressure is (2.5-4.5)×10 -1 Pa, use pure silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com