Ink composition, method for forming near-infrared light anti-reflection layer on substrate surface, and near-infrared light anti-reflection material

An ink composition, near-infrared light technology, applied in the directions of ink, optics, optical components, etc., can solve the problems of low transmittance of dark near-infrared light and near-infrared light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Weigh the raw materials according to the formula shown in Table 1, then slowly add the additives dropwise into the solvent and stir for 5 minutes; then add pearlescent powder, titanium dioxide and matting powder in turn, and stir for 10 minutes; then add fluorescent whitening agent, stirred for 10 minutes; finally added the resin, stirred for 15 minutes to obtain a white ink, and obtained the ink composition S1 of this embodiment.

[0038] (2) Print the ink composition S1 on a transparent glass substrate with a thickness of 0.8 mm using a 300-mesh polyester screen with a thickness of 15 μm and a 75-degree (Shore hardness unit) glue blade, and then cure it at 150 ° C After 30 minutes, a first layer of coating with a thickness of 8 μm was formed on the surface of the transparent glass, and the obtained sample was designated as S10.

[0039] (3) On the surface of the first layer of S10, continue to screen-print Nippon Seiko's BMR-008-107C dark blue near-infrared light-...

Embodiment 2-4

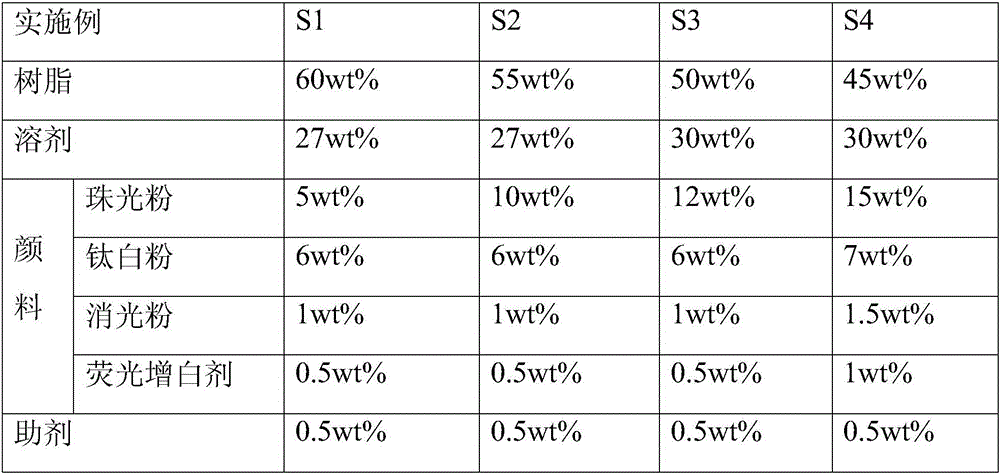

[0041] Ink compositions S2-S4, samples S20-S40, and near-infrared anti-reflection materials S22-S44 were prepared in the same steps as in Example 1, except that the ratio of raw materials in step (1) is shown in Table 1.

[0042] Table 1

[0043]

[0044] Note: In the above table 1, the resin is epoxy acrylic resin; the solvent is a mixed solvent of ethylene glycol butyl ether and butyl acetate with a mass ratio of 3:2; the pearl powder is CQV R-901S, with an average particle size of 10 μm; titanium The white powder is TRONOX R 828; the matting powder is Degussa OK520; the fluorescent whitening agent is CibaOB.

Embodiment 5

[0046] Using the same ink composition S1 and the same steps as in Example 1 to prepare sample S50 and near-infrared anti-reflection material S55, the difference is that in step (2), the curing temperature is 145 ° C, and the curing time is 1 hour. The thickness of the first layer of coating is 10 μm; in step 3, the curing temperature is 160° C., the curing time is 30 minutes, and the thickness of the second layer of coating is 8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com