Environment-friendly high-reflection coating material and preparation method thereof

A technology of coating materials and highly reflective fillers, applied in reflective/signal coatings, coatings, etc., to solve problems such as pungent odor and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

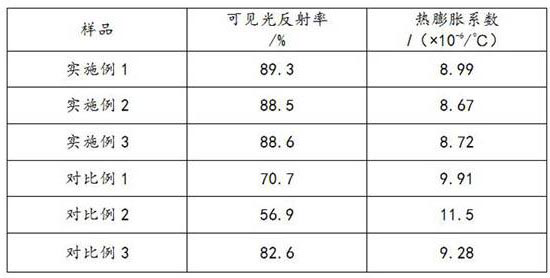

Examples

Embodiment 1

[0037] This embodiment is an environment-friendly high-reflection coating material, comprising the following steps:

[0038] S1: The inorganic environmental protection flux is melted, quenched, dried, and then ball milled to a particle size of 0.5 μm;

[0039] S2: Mix titanium dioxide, calcium sulfate, inorganic environmental protection flux, zirconium silicate, tin oxide, barium sulfate, high-reflective filler and high-temperature binder, ball mill and disperse, then precipitate, dehydrate, dry, and powder to obtain a blend material;

[0040] S3: adding varnish to the blend for grinding and dispersing to obtain a highly reflective coating material;

[0041] Wherein the preparation process of high temperature adhesive is as follows:

[0042] S31: Prepare phosphoric acid as a phosphoric acid solution, add it to a beaker, heat it in a water bath to 80° C., start mechanical stirring, add aluminum hydroxide, and stir for 10 hours to obtain intermediate A;

[0043] S32: Add mull...

Embodiment 2

[0049] This embodiment is an environment-friendly high-reflection coating material, comprising the following steps:

[0050] S1: The inorganic environmental protection flux is melted, quenched, dried, and then ball milled to a particle size of 0.5 μm;

[0051] S2: Mix titanium dioxide, calcium sulfate, inorganic environmental protection flux, zirconium silicate, tin oxide, barium sulfate, high-reflective filler and high-temperature binder, ball mill and disperse, then precipitate, dehydrate, dry, and powder to obtain a blend material;

[0052] S3: adding varnish to the blend for grinding and dispersing to obtain a highly reflective coating material;

[0053] Wherein the preparation process of high temperature adhesive is as follows:

[0054] S31: Prepare phosphoric acid as a phosphoric acid solution, add it to a beaker, heat it in a water bath to 90° C., start mechanical stirring, add aluminum hydroxide, and stir for 12 hours to obtain intermediate A;

[0055] S32: Add mull...

Embodiment 3

[0061] This embodiment is an environment-friendly high-reflection coating material, comprising the following steps:

[0062] S1: The inorganic environmental protection flux is melted, quenched, dried, and then ball milled to a particle size of 0.5 μm;

[0063] S2: Mix titanium dioxide, calcium sulfate, inorganic environmental protection flux, zirconium silicate, tin oxide, barium sulfate, high-reflective filler and high-temperature binder, ball mill and disperse, then precipitate, dehydrate, dry, and powder to obtain a blend material;

[0064] S3: adding varnish to the blend for grinding and dispersing to obtain a highly reflective coating material;

[0065] Wherein the preparation process of high temperature adhesive is as follows:

[0066] S31: Prepare phosphoric acid as a phosphoric acid solution, add it to a beaker, heat it in a water bath to 90° C., start mechanical stirring, add aluminum hydroxide, and stir for 12 hours to obtain intermediate A;

[0067] S32: Add mull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com