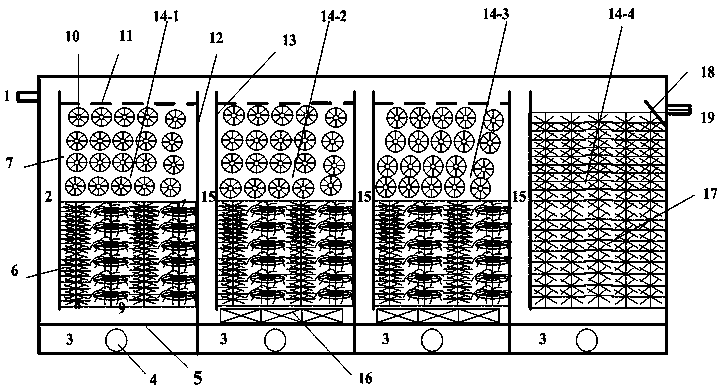

A biofilm pretreatment device suitable for the purification of polluted raw water

A pretreatment device and biofilm technology, applied in sustainable biological treatment, aerobic process treatment and other directions, can solve the problems of delaying the normal operation of water plants, increasing the difficulty of daily management and maintenance, and single habitat for biofilm operation, so as to improve adhesion Diversity of environmental and microbial species, reducing the risk of disinfection by-products, and overcoming the effect of a single aerobic habitat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The effective volume of the reaction device is 2.4m 3 , divided into four processing units 14 by the water inlet and drainage area 2, a screen 20 with a height h1 of 0.1 m is arranged on the top of the partition plate 12, and the mesh aperture of the screen 20 and the flow net 18 is 2 cm. The anti-floating screen 11 is located at a position 10 cm underwater, and the mesh aperture of the screen 11 is 3 cm. The first processing unit 14-1, the second processing unit 14-2, and the third processing unit 14-3 have a ratio of 1:1 between the volume V1 of the lower suspended packing area 6 and the volume V2 of the upper suspended packing area 7, and the lower suspended packing area 6 The volume ratio of the elastic filler 8 and the combined filler 9 is 0.5:1, the distance between the elastic filler 8 and the combined filler 9 is -10 cm, the upper suspended filler area 7 is filled with suspended filler 10, and its density is 0.92 kg / m 3, using suspension ball packing, its diame...

Embodiment 2

[0037] The effective volume of the reaction device is 2.4m 3 , divided into four processing units 14 by the water inlet and drainage area 2, a screen 20 with a height h1 of 0.5 m is arranged on the top of the partition plate 12, and the mesh aperture of the screen 20 and the flow net 18 is 5 cm. The anti-floating screen 11 is located at a position 10 cm underwater, and the mesh aperture of the screen 11 is 5 cm. The ratio of the volume V1 of the lower suspended packing area 6 to the volume V2 of the upper suspended packing area 7 is 2:1, the volume ratio of the elastic packing 8 combined packing 9 arranged in the lower hanging packing area 6 is 3:1, the elastic packing 8 and the combined packing 9 The distance between them is 10cm, and the upper suspended packing area 7 is filled with suspended packing 10, whose density is less than 0.89 kg / m 3 , using suspension ball packing with a diameter of 10cm (more than 30% of the hole diameter of the screen 20 at the top of the floati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com