Chain cleaning oiling device

A chain cleaning and equipment technology, applied to metal chains and other directions, can solve the problems of inability to meet the needs of use, incomplete cleaning, time-consuming and labor-intensive, etc., and achieve the effects of saving manpower, uniform oiling, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

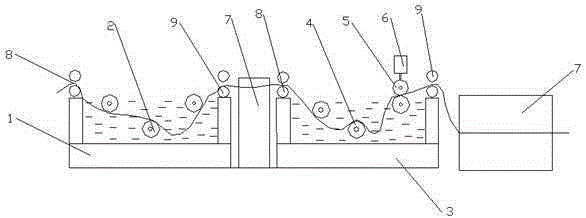

[0016] A chain cleaning and oiling device according to the present invention includes a cleaning device and an oiling device, and the cleaning device includes a cleaning box 1 for placing cleaning liquid and a plurality of cleaning rollers 2 with different heights arranged inside the cleaning box 1 , the oiling device includes an oil storage box 3 for storing chain oil and a plurality of oiling rollers 4 with different heights arranged inside the oil storage box 3, and a pressing roller 4 is arranged above the last oiling roller 4 inside the oil storage box 3. Roller 5, pressing roller 5 is connected 6 with air cylinder.

[0017] Preferably, as a possible embodiment, a dryer 7 is provided behind the oiling device.

[0018] A drier 7 is arranged between the cleaning box body 1 and the oil storage box body 3 .

[0019] Preferably, as another possible embodiment, guide rollers 8 are provided at the chain inlets of the cleaning box 1 and the oil storage box 3 , and tension roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com