Environment-friendly and efficient levodopa production method

A technology of levodopa and its production method, which is applied in the field of medicine, can solve problems such as high pressure on environmental protection and unqualified environmental assessment of manufacturers, and achieve the effects of saving energy, reducing production operations, and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

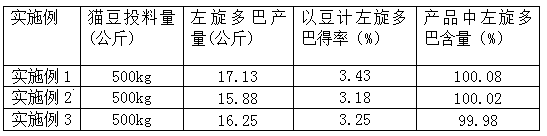

Embodiment 1

[0038] An environment-friendly and efficient production method for levodopa, comprising the following steps:

[0039] (1) Pretreatment: take dry cat beans with complete granules, add ethanol with a volume fraction of 85% by 4 times the weight of cat beans, reflux heating for 2 hours, and drain the ethanol after cooling for use;

[0040] (2) Add 10 times the amount of solution A, dynamically extract for 9 hours, and retain the extract;

[0041] (3) Add 12 times the amount of solution B or the extract obtained in step (5), perform dynamic extraction for 6 hours, and retain the extract;

[0042] (4) Extract with 10 times the amount of solution B, dynamically extract for 9 hours, and retain the extract;

[0043] (5) leaching with 12 times the amount of solution B, dynamic extraction for 6 hours, and the obtained leaching solution is used as the leaching solution of step (3) in the next production;

[0044] (6) Combine the three leaching solutions of steps (2) to (4), concentrate...

Embodiment 2

[0050] An environment-friendly and efficient production method for levodopa, comprising the following steps:

[0051] (1) Pretreatment: take dry cat beans with complete granules, add ethanol with a volume fraction of 6 times the weight of cat beans and 100% ethanol, reflux heating for 0.5 hours, and dry the ethanol after cooling for use;

[0052] (2) Add 9 times the amount of solution A, dynamically extract for 6 hours, and retain the extract;

[0053] (3) Add 10 times the amount of solution B or the leaching solution obtained in step (5), perform dynamic extraction for 3 hours, and retain the leaching solution;

[0054] (4) leaching with 8 times the amount of solution B, dynamic extraction for 9 hours, and retaining the leaching solution;

[0055] (5) leaching with 15 times the amount of solution B, dynamic extraction for 9 hours, and the obtained leaching solution is used as the leaching solution of step (3) in the next production;

[0056] (6) Combine the three leaching s...

Embodiment 3

[0062] An environment-friendly and efficient production method for levodopa, comprising the following steps:

[0063] (1) Pretreatment: Take dry cat beans with complete granules, add ethanol with a volume fraction of 75% 8 times the weight of cat beans, reflux heating for 1.5 hours, and drain the ethanol after cooling for use;

[0064] (2) Add 8 times the amount of solution A, dynamically extract for 3 hours, and retain the extract;

[0065] (3) Add 15 times the amount of solution B or the leaching solution obtained in step (5), perform dynamic extraction for 9 hours, and retain the leaching solution;

[0066] (4) leaching with 10 times the amount of solution B, dynamic extraction for 3 hours, and retaining the leaching solution;

[0067] (5) leaching with 10 times the amount of solution B, dynamic extraction for 8 hours, and the obtained leaching solution is used as the leaching solution of step (3) in the next production;

[0068] (6) Combine the three leaching solutions o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com